Removing

Before you start removing parts, do the following:

- A) Remove the decorative engine cover.

- b) Remove the engine crankcase guard.

- V) Remove the support bracket and engine support assembly.

- G) Remove the alternator adjuster.

Removal of parts is carried out in the order of the numbers indicated in the figures "Removing the crankshaft pulley" And "Timing Belt Replacement".

When removing parts, pay attention to the following operations:

1. Removing the drive belt for the power steering pump and air conditioning compressor.

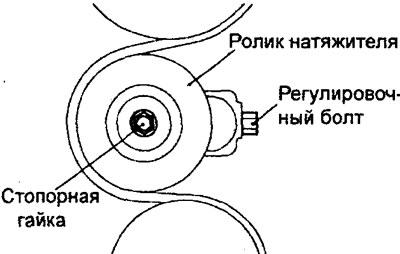

A) Loosen the lock nut of the belt tensioner pulley for the power steering pump and air conditioning compressor.

b) Loosen the adjusting bolt to release the belt tension, then remove the belt.

Attention: in case of reuse of the drive belt of the power steering pump and air conditioning compressor, it is necessary to chalk on the back (non-working) belt surface an arrow indicating the direction of rotation (clockwise).

2. Removing the alternator drive belt.

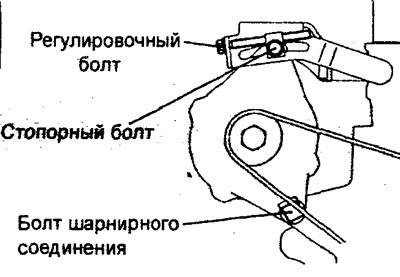

A) Loosen the set bolt on the alternator adjusting bar and the swivel bolt.

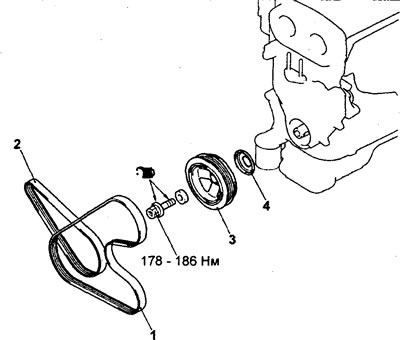

Removing the crankshaft pulley (4G93 engine). 1 - drive belt for power steering pump and air conditioning compressor, 2 - generator drive belt, 3 - crankshaft pulley, 4 - guide plate.

b) Loosen the alternator drive belt by turning the adjusting bolt, then remove the belt.

Attention: in case of reusing the alternator drive belt, it is necessary to chalk on the back (non-working) belt surface an arrow indicating the direction of rotation (clockwise).

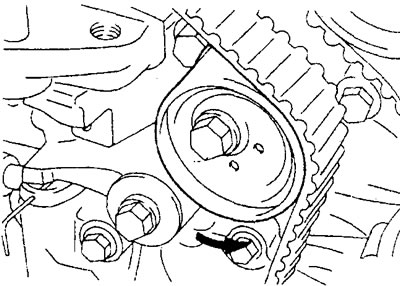

3. Removing the crankshaft pulley.

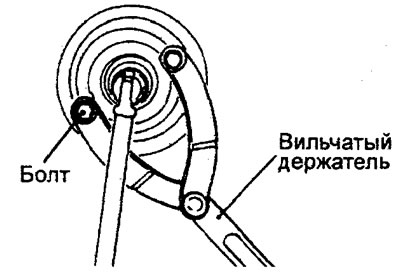

Using the special tool, fix the crankshaft pulley from turning and unscrew the crankshaft pulley mounting bolt.

Caution: secure the special tool securely so that it does not move.

4. Removing the timing belt.

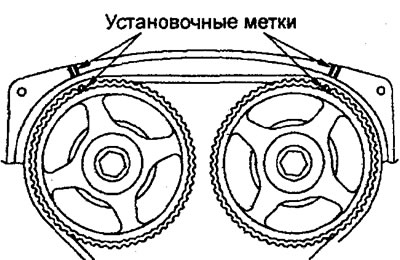

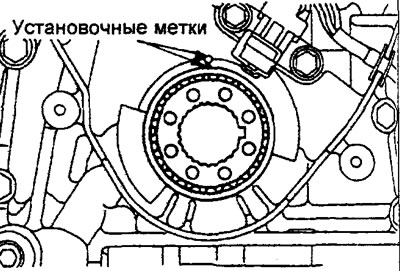

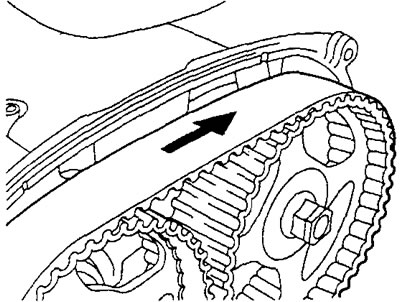

A) Turn the crankshaft clockwise until the timing marks on the camshaft pulleys and the crankshaft sprocket are aligned with the corresponding timing marks to set the #1 cylinder piston to TDC on the compression stroke.

Caution: Always turn the crankshaft in a clockwise direction only.

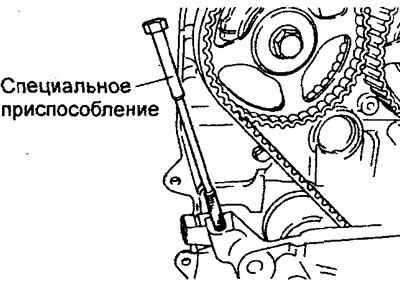

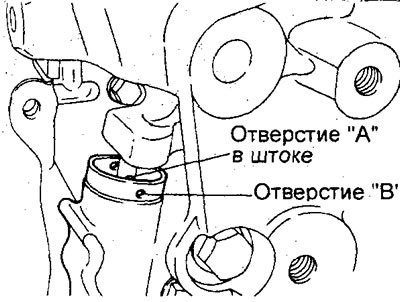

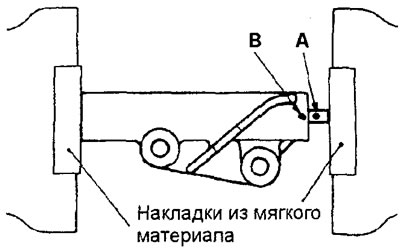

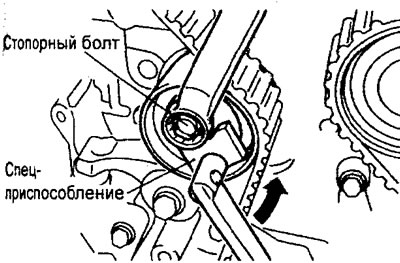

If the timing belt tensioner must not be removed or removed with a fixed rod, then:

Screw the special rod into the hole of the attachment mounting bracket so that it rests against the groove on the tensioner arm.

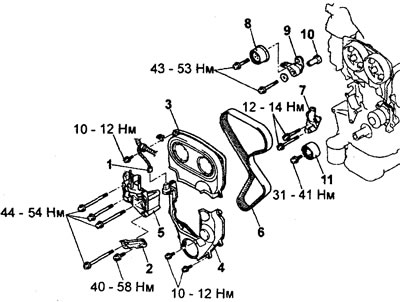

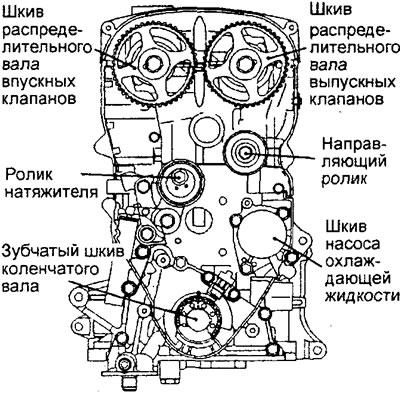

Timing Belt Replacement (4G93 engine). 1 - crankshaft position sensor connector, 2 - power steering pump strut, 3 - front upper timing belt cover, 4 - front lower timing belt cover, 5 - engine side support bracket, 6 - timing belt, 7 - tensioner timing belt (auto), 8 - tensioner roller, 9 - tensioner roller lever, 10 - bushing, 11 - guide roller.

- Slowly screw in the special rod to align the hole "IN" on the tensioner housing with a hole "A" on the tensioner rod.

Attention: when the rod hits the tensioner lever, unscrew it by 30°for 1 second, then continue to screw it in again. If the rod is difficult to turn, then be careful not to bend the tensioner rod.

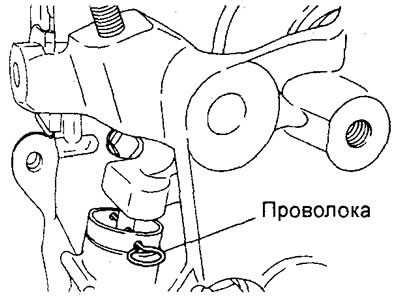

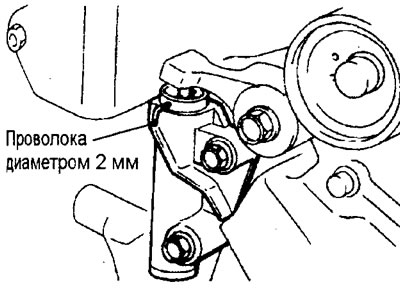

- Insert hard "L''-shaped wire with a diameter of 2 mm into the hole in the tensioner housing.

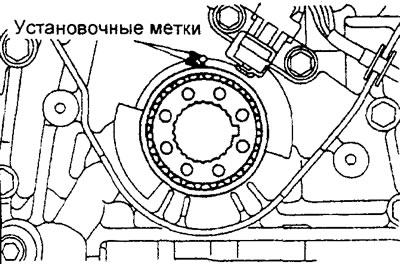

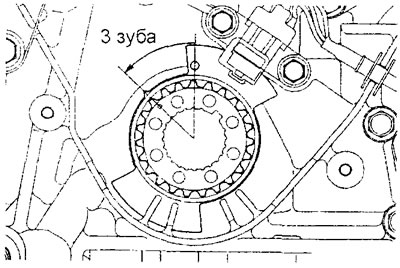

V) Rotate the crankshaft if necessary and position the crankshaft sprocket mark 3 teeth to match the matching mark on the cylinder block.

Attention: if all the alignment marks are not aligned, the valves may "meet" with piston) turning the camshaft pulley when the piston is at TDC.

G) Loosen the tensioner roller adjusting bolt and remove the timing belt.

Attention: in case of reusing the timing belt, it must be chalked on the back (non-working) belt surface an arrow indicating the direction of rotation (clockwise).

Examination

Checking the timing belt tensioner

1. Check tensioner for oil leaks. If there are leaks, replace the timing belt tensioner.

2. Check the rod for wear and damage, if necessary, replace the timing belt tensioner.

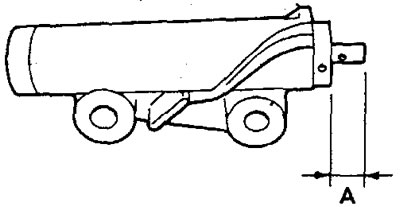

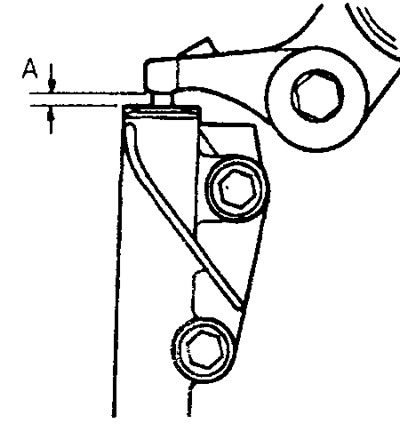

3. Measure the stem protrusion. If this value does not correspond to the nominal value, then replace the timing belt tensioner.

Rated value (A) - 11 mm

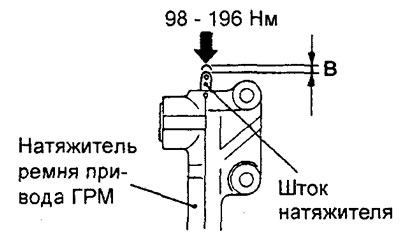

4. Take the timing belt tensioner in hand. Press on the tensioner (for example, resting it on the cylinder block), applying a force of 98-196 N, and then measure the stroke of the rod "IN". If the stroke is out of specification, replace the timing belt tensioner.

Rated value (IN) - 1 mm or less

Note: This check can be done with a vise. When installing the tensioner body in a vise, make sure that the body is not skewed in relation to the jaws of the vise. If the stem sinks easily, replace the tensioner. If the tensioner is working, then sinking the rod requires considerable effort.

Checking the tensioner pulley and guide pulley

Note: When replacing the timing belt, it is recommended that all rollers be replaced at the same time.

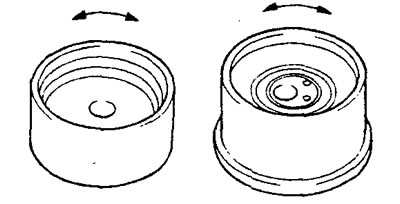

1. Check the ease and smoothness of the rotation of the rollers.

2. Make sure there is no excessive play in the bearings and no extraneous noise when the roller rotates. Replace if necessary.

Installation

Attention:

- Since water or oil can seriously reduce the life of the timing belt, when removing parts, ensure that the timing belt, pulleys and tensioner bracket are clean and dry, never wash them. Contaminated parts must be replaced.

- If any of the parts are oily, then check for oil leakage through the seals (including front camshaft oil seal).

- Check up a condition and smoothness of rotation of a roller of a tensioner.

- If a used timing belt is installed, check its condition.

Installation is made in an order, the return to removal.

When installing parts, pay attention to the following operations:

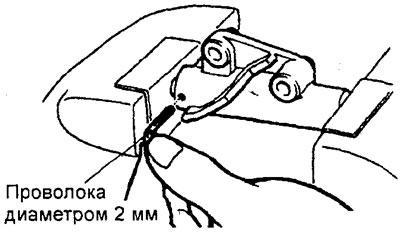

1. Installing the timing belt tensioner (if the tensioner rod is in its fully extended position).

A) Place the timing belt tensioner in a soft grip vise.

b) Gradually squeezing the vise, push the timing belt tensioner rod in as slowly as possible until the hole is aligned "A" in stem with hole "IN" in the tensioner housing.

Attention:

- The tensioner must be installed at a right angle to the vise jaw surface, without distortion.

- If the stem is pushed in too quickly, it may be damaged or bent, so do this operation slowly.

b) Insert a wire with a diameter of 2 mm into the hole for fixing the rod in the tensioner body.

Note: the wire must be strong enough (piano wire type, etc.), and should be bent at a right angle (in the shape of "L").

V) Attach the timing belt tensioner to the engine, tighten the mounting bolts to the specified torque.

Tightening torque 12 -14 N.m

2. Installing the timing belt.

Attention:

- Install the timing belt so that the belt tension does not loosen between the pulleys and rollers.

- Install a used belt so that the arrow on the back of it matches the direction of rotation of the belt (clockwise).

A) Loosen the tensioner adjusting bolt.

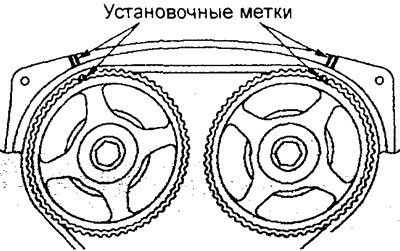

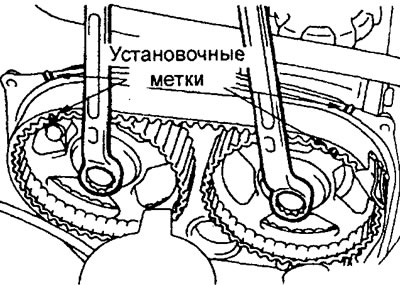

b) Check that the marks on the camshaft pulleys and the crankshaft sprocket are aligned with the corresponding alignment marks (while the piston of cylinder No. 1 will be at TDC of the compression stroke). If all the marks are aligned, then go to subparagraph "d".

Attention: if the alignment marks are not aligned, the valves may "meet" with the piston when turning the camshaft pulley when the piston is at TDC.

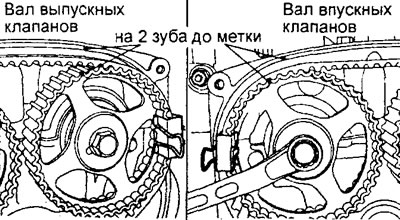

V) If the alignment marks are not aligned, then they must be aligned as follows:

- Carefully turn the crankshaft so that the mark on the crankshaft sprocket does not reach the mark on the cylinder block by three teeth (i.e. the piston of cylinder No. 1 does not reach the TDC of the Compression stroke a little).

- Rotate the camshafts and align the pulley marks with the alignment marks as shown in the figure.

Attention: when turning the camshaft pulley one full turn (to match labels), when the other camshaft pulley remains stationary (labels aligned), there may be a collision between the intake and exhaust valves due to a violation of the valve timing.

- Align the mark on the crankshaft sprocket with the alignment mark on the oil pump housing.

G) To simplify work, it is allowed to leave the pulleys in a position where the marks on the camshaft pulleys are 2 teeth, and the crankshaft toothed pulley mark is 3 teeth to the corresponding alignment marks on the cylinder block. In this case, the belt is installed starting from the camshaft pulleys. Further, when installing the belt on the crankshaft toothed pulley, it must be turned clockwise by 1 tooth.

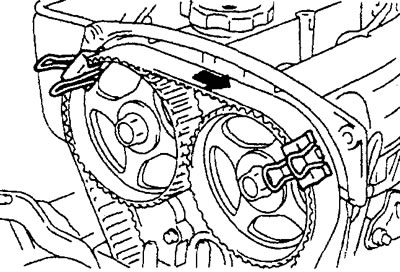

d) Install the timing belt to the crankshaft sprocket, then to the water pump pulley and idler pulley.

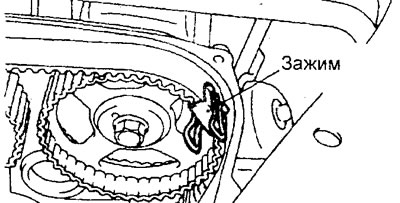

e) Install the timing belt on the exhaust camshaft pulley and secure the belt with a clip in the position shown in the figure.

and) Make sure the pulley marks are aligned with the alignment marks» and, fixing the relative position of the camshaft pulleys with two wrenches, install the timing belt on the intake camshaft pulley.

h) Using another clip, secure the timing belt to the intake camshaft pulley in the position shown in the illustration.

And) Install the timing belt on the belt tensioner pulley.

To) Insert the pins of the special tool into the 2 holes of the tensioner roller, lift the tensioner roller in the direction of the arrow, and tighten the tensioner roller lock bolt.

l) Remove the two clips that secure the belt to the pulleys.

m) Make sure all the timing marks are aligned, then adjust the timing belt tension.

3. Adjustment of the timing belt tensioner.

A) First turn the crankshaft 1/4 turn counterclockwise, then turn the crankshaft clockwise to align the timing marks.

b) Loosen the tensioner pulley lock bolt and use the special tool and torque wrench to apply torque to the tensioner pulley (tighten the belt).

The nominal value is applied to the tensioner roller - 2.6 N.m

V) Then, while holding the tensioner roller from turning with a special tool, tighten the lock bolt to the rated torque.

Caution: When tightening the stop bolt, make sure that the idler roller shaft does not rotate with the bolt.

G) Remove the L-shaped wire that was inserted into the hole in the timing belt tensioner housing (for fixing the stem).

Note: before removing, make sure that the wire can be easily removed from the hole in the tensioner body.

d) Turn the crankshaft clockwise two turns and align the timing marks.

e) Wait at least five minutes and then check again that "The L''-shaped wire can be easily installed in and out of the timing belt tensioner. If the wire cannot be easily inserted into the timing belt tensioner hole, then check that the protrusion of the tensioner rod is within the nominal range.

Rated value (A) 3.8 - 4.5 mm

and) If the protrusion of the stem does not correspond to the range of nominal values, then repeat the operations according to p.p. With "A" By "and".

h) Check again that the marks on all pulleys are aligned with the alignment marks.

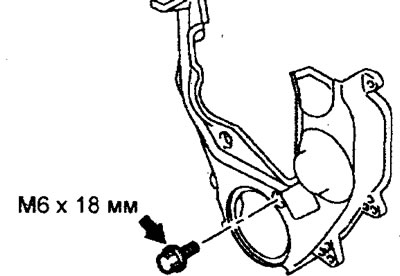

4. Installing the front lower timing belt cover.

A) Install the bolt shown in the figure first.

b) Install the remaining bolts, tighten them to the nominal torque.

Tightening torque - 10 -12 N·m

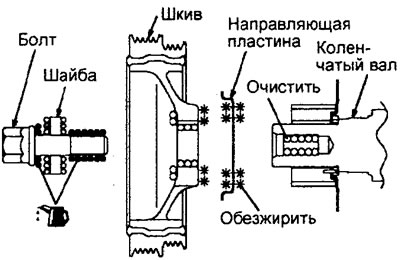

5. Installation of the guide plate and crankshaft pulley.

A) Clean then degrease the surface of the crankshaft pulley in contact with the guide plate.

Note: degreasing is necessary to improve the mating of parts.

b) Clean the threaded hole in the end of the crankshaft, the end of the shaft, the pulley bolt washer and the surfaces in contact with it.

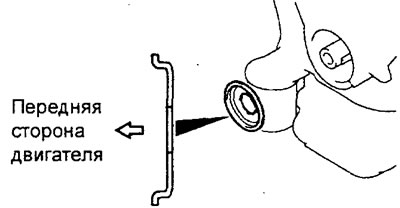

V) Install the guide plate on the crankshaft, positioning it as shown in the figure.

G) Lubricate the mating surface with a minimum amount of engine oil (cone) crankshaft nose and crankshaft bolt threads.

d) Before installing the crankshaft pulley bolt, it is necessary to install the bolt washer with the chamfered side to the bolt.

e) Using the special tool, stop the crankshaft pulley from turning or stop the flywheel from turning, and install the crankshaft pulley mounting bolt to the specified torque.

Tightening torque - 178- 186 N.m

Attention: securely fasten the special tool so that it does not rotate.

After completing the installation of the parts, perform the following operations:

- A) Establish an adjusting lath of the generator.

- b) Install the support bracket and engine mount assembly.

- V) Install the engine crankcase guard.

- G) Adjust the tension of the accessory drive belts (see chapter "Maintenance and general inspection and adjustment procedures").

- d) Install the decorative engine cover.