Removing

Before you start removing parts, do the following:

- A) Remove the decorative engine cover.

- b) Remove the engine crankcase guard.

- V) Remove the support bracket and engine support assembly.

Removal of parts is carried out in the order of the numbers indicated in the figures "Removing the crankshaft pulley" And "Timing Belt Replacement".

When removing parts, pay attention to the following operations:

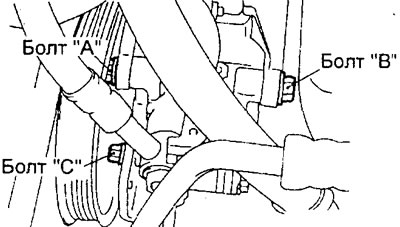

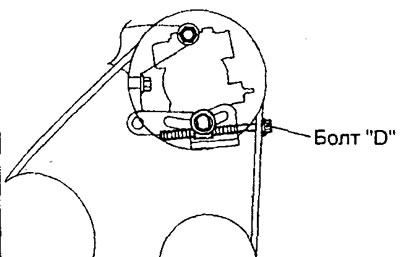

1. Removing the drive belt for the power steering pump and air conditioning compressor.

A) Loosen the bolts "A", "IN" And "WITH" power steering pump.

b) Loosen the adjusting bolt "D" to relieve belt tension, then remove the belt.

Attention: in case of reuse of the drive belt of the power steering pump and air conditioning compressor, it is necessary to chalk on the back (non-working) belt surface an arrow indicating the direction of rotation (clockwise).

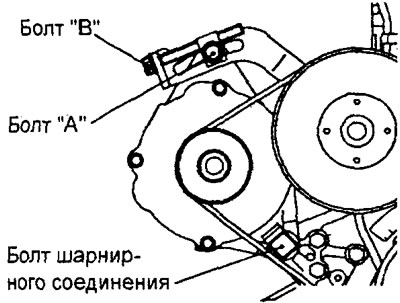

2. Removing the alternator drive belt.

A) Loosen the lock bolt "A" on the alternator adjustment bar and the swivel bolt.

b) Turning the adjusting screw "IN" release the tension on the alternator drive belt, then remove the belt.

Attention: in case of reusing the alternator drive belt, it is necessary to chalk on the back (non-working) belt surface an arrow indicating the direction of rotation (clockwise).

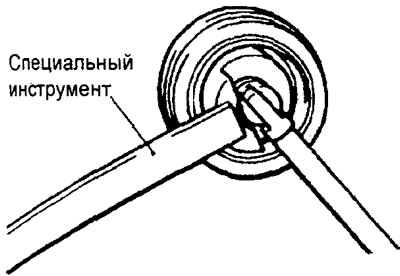

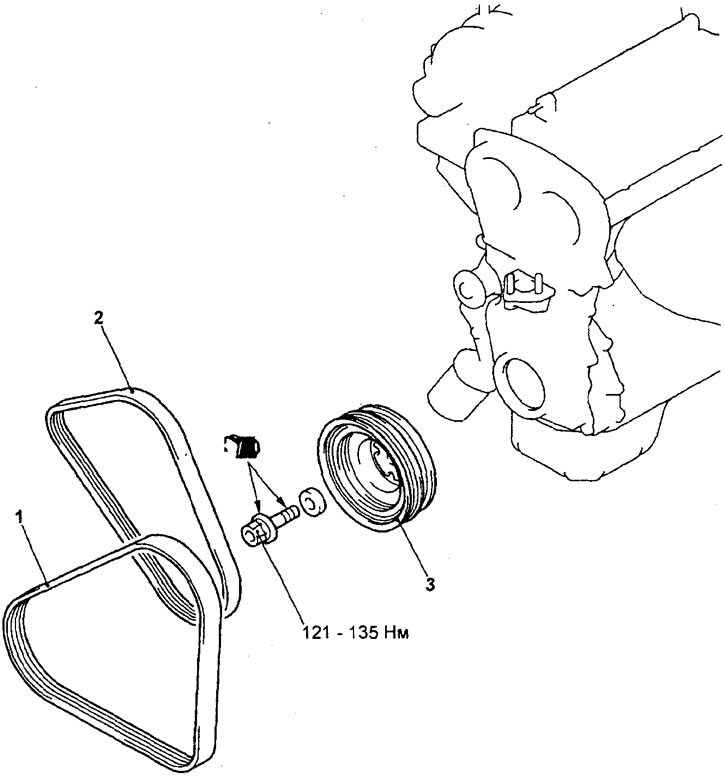

3. Removing the crankshaft pulley.

Using the special tool, fix the crankshaft pulley from turning and unscrew the crankshaft pulley mounting bolt.

Caution: secure the special tool securely so that it does not move.

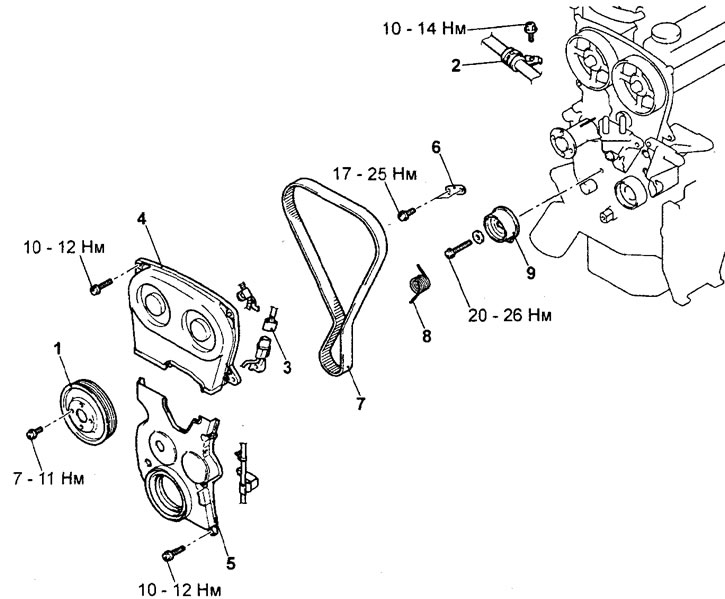

4. Removing the timing belt.

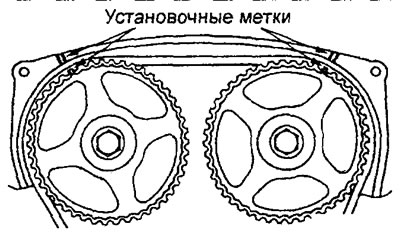

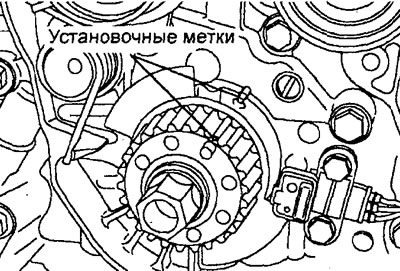

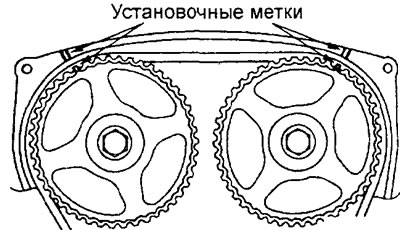

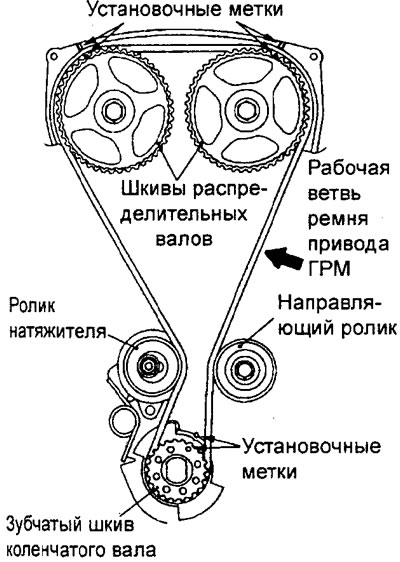

A) Turn the crankshaft clockwise until the timing marks on the camshaft pulleys and the crankshaft sprocket are aligned with the corresponding timing marks for setting the No. 1 cylinder piston to TDC on the compression stroke.

Caution: Always turn the crankshaft in a clockwise direction only.

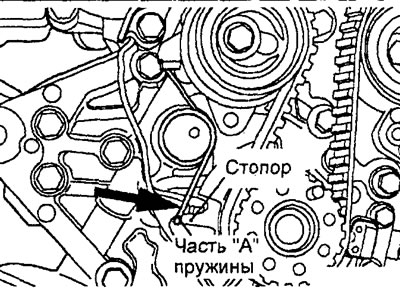

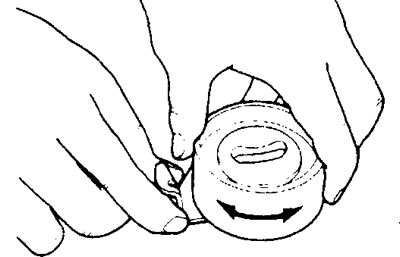

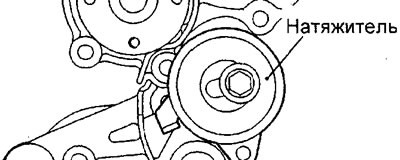

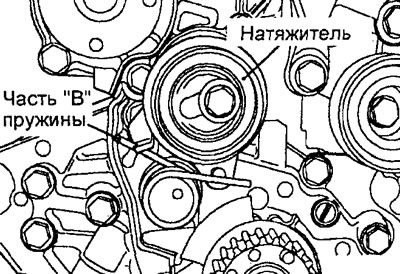

b) Use pliers to pull out part "A" tensioner springs on the stopper on the oil pump housing, then remove the spring.

Note: Be careful when removing the tensioner spring, do not damage the timing belt with part "A" springs when it is straightened.

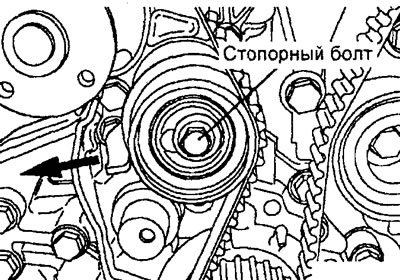

V) Loosen the timing belt tensioner lock bolt.

G) Move the timing belt tensioner in the direction of the arrow shown in the figure to release the belt tension.

Removing the crankshaft pulley (4G15 engine).1 - drive belt for power steering pump and air conditioning compressor (models with air conditioning), 2 - alternator drive belt, 3 - crankshaft pulley.

Timing Belt Replacement (4G15 engine). 1 - coolant pump pulley, 2 - power steering hydraulic pressure hose retainer, 3 - crankshaft position sensor connector, 4 - front upper timing belt cover, 5 - front lower timing belt cover, 6 - bracket, 7 - belt timing drive, 8 - tensioner spring, 9 - timing belt tensioner.

d) Remove the timing belt.

Attention: in case of reusing the timing belt, it must be chalked on the back (non-working) belt surface an arrow indicating the direction of rotation (clockwise).

Examination

Note: When replacing the timing belt, it is recommended to replace the tensioner and tensioner spring.

1. Check the ease and smoothness of the rotation of the rollers.

2. Make sure there is no excessive play in the bearings and no extraneous noise when the roller rotates. Replace if necessary.

3. Check up a condition of a spring and an arm of a tensioner.

Installation

Attention:

- Since water or oil can seriously reduce the life of the timing belt, when removing parts, ensure that the timing belt, pulleys and tensioner bracket are clean and dry, never wash them. Contaminated parts must be replaced.

- If any of the parts are oily, then check for oil leakage through the seals (including front camshaft oil seal).

- Check up a condition and smoothness of rotation of a roller of a tensioner.

- If a used timing belt is installed, check its condition (see chapter "Maintenance and general inspection and adjustment procedures").

Installation is made in an order, the return to removal.

When installing parts, pay attention to the following operations:

1. Installing the timing belt tensioner.

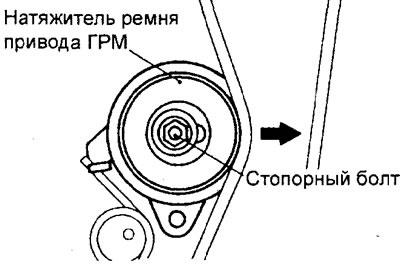

A) Set the timing belt tensioner to the position shown in the figure and temporarily tighten the lock bolt.

b) Install the tensioner spring

V) Get the part "IN" tensioner springs for the tensioner bracket.

V) Use pliers to cut the part "A" tensioner springs for the stopper on the oil pump housing.

2. Installing the timing belt.

Attention:

- Install the timing belt so that the belt tension does not loosen between the pulleys and rollers.

- Install a used belt so that the arrow on the back of it matches the direction of rotation of the belt (clockwise).

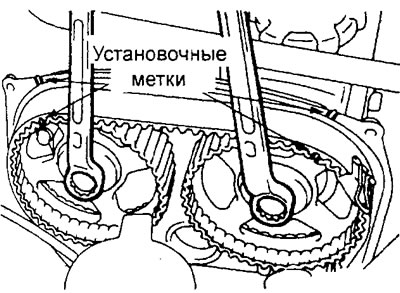

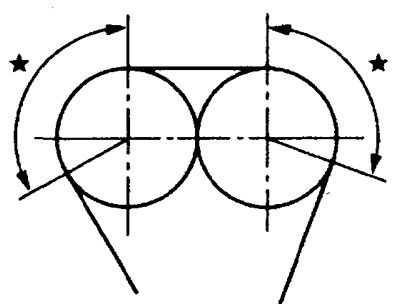

A) Check that the marks on the camshaft pulleys and the crankshaft sprocket are aligned with the corresponding alignment marks (while the piston of cylinder No. 1 will be at TDC of the compression stroke).

Attention: if the alignment marks are not aligned, the valves may "meet" with the piston when turning the camshaft pulley when the piston is at TDC.

b) Install the timing belt (avoiding belt slack between pulleys and rollers) on the crankshaft sprocket and idler roller.

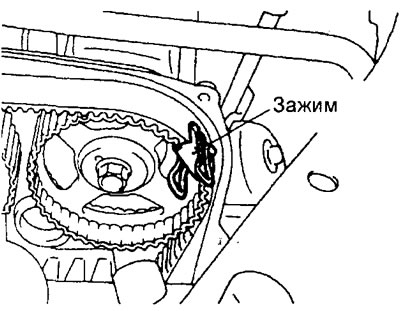

V) Maintaining tension on the belt, install the timing belt to (the exhaust camshaft pulley and secure the belt with a clip in the position shown in the figure.

G) Make sure that the pulley marks are aligned with the alignment marks and, fixing the relative position of the camshaft pulleys with two wrenches, install the timing belt on the intake camshaft pulley.

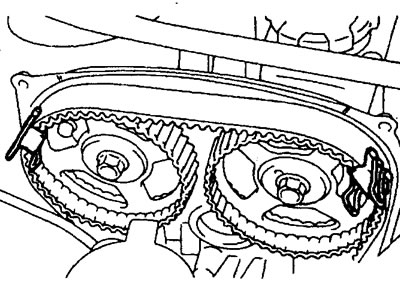

d) Using another clip, secure the timing belt to the intake camshaft pulley in the position shown in the illustration.

e) Maintaining tension on the belt, install the timing belt onto the tensioner pulley.

and) Remove the two clips that secure the belt to the pulleys.

Attention: after installing the timing belt, apply force to the camshaft pulley to turn it counterclockwise and check that the belt is fully tensioned and all the timing marks are aligned.

3. Adjusting the tension of the timing belt.

A) Loosen the lock bolt 1/4 to 1/2 turn so that the timing belt is tensioned by the tensioner spring force.

b) Turn the crankshaft in the direction of rotation (clockwise) 2 turns and make sure that all the marks on the pulleys are aligned with the corresponding alignment marks.

Attention: since the purpose of this operation is to apply the appropriate tension to the working branch of the timing belt using the torque on the camshaft, turn the crankshaft only two turns. It is forbidden to turn the crankshaft in the opposite direction (counterclock-wise).

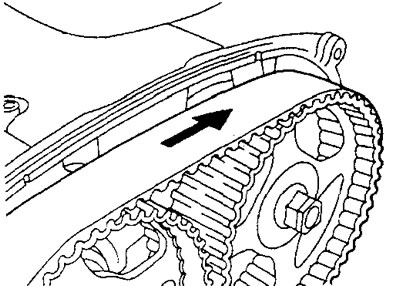

V) Check that there is no protrusion of the teeth of the timing belt relative to the camshaft pulley in the sector "A", shown in the figure, and the normal engagement of the timing belt with the pulleys is ensured. After that, tighten the tensioner pulley lock bolt to the specified torque.

Tightening torque - 20 - 26 N.m

4. Installing the crankshaft pulley.

A) Clean the threaded hole in the end of the crankshaft, the end of the shaft, the pulley bolt washer and the surfaces in contact with it.

b) Lubricate the mating surface with a minimum amount of engine oil (cone) crankshaft toe and crankshaft pulley bolt thread.

V) Before installing the crankshaft pulley bolt, it is necessary to install the bolt washer with the chamfered side to the bolt.

G) Using a special tool, fix the crankshaft pulley from turning, install and tighten the crankshaft pulley bolt to the nominal torque.

Tightening torque - 121 -135 N.m

After completing the installation of the parts, perform the following operations:

- A) Install the support bracket and engine mount assembly.

- b) Install the engine crankcase guard.

- V) Adjust the tension of the accessory drive belts (see chapter "Maintenance and general inspection and adjustment procedures").

- G) Install the decorative engine cover.