Removing

Perform the following operations before beginning to remove parts.

A) Remove the decorative engine cover.

b) Release residual pressure from the high pressure line (see chapter "fuel injection system (GDI)").

V) Remove the engine crankcase guard.

G) Drain coolant and engine oil.

d) Remove the air filter.

e) Remove the battery and battery tray.

and) Remove the accessory drive belts and timing belt.

h) Remove the cylinder head covers and gaskets.

And) (Engine 4G15) Remove the inlet pipe of the cooling system.

To) (Engine 4G93) Remove the thermostat housing assembly.

l) (Engine 4G15) Remove the alternator adjuster.

m) (Engine 4G93) Remove the EGR valve actuator.

Removal of parts is carried out in the order of the numbers indicated in the figure "Replacing the cylinder head gasket".

When removing parts, pay attention to the following operations:

1. (Engine 4G93) Removing the upper radiator hose.

Before disconnecting the upper radiator hose, mark the relative position on the hose and hose clamp.

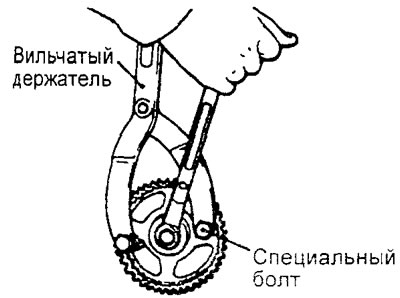

2. (Engine 4G93) Removing the camshaft pulley.

Secure the camshaft pulley against rotation using a special fork holder and special bolts.

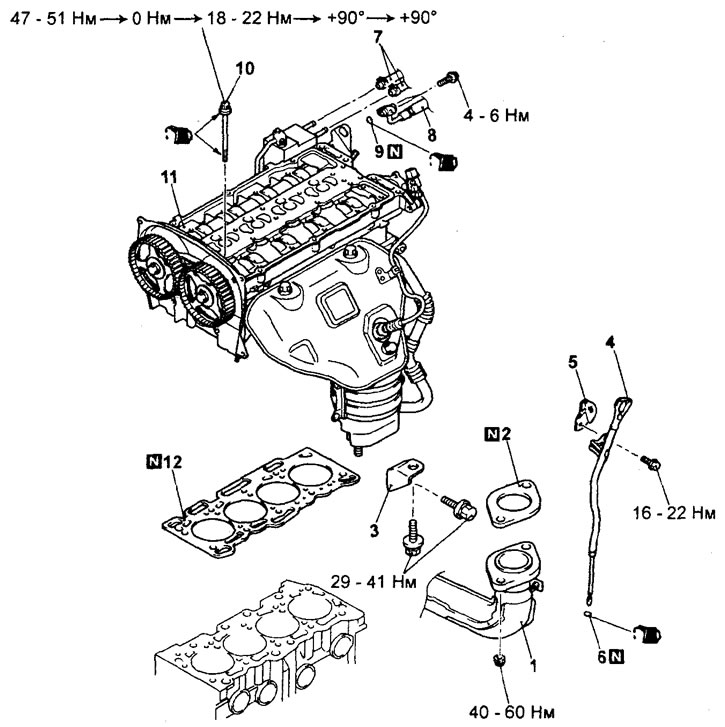

Replacing the cylinder head gasket (4G15 engine).1 - exhaust pipe connection, 2 - gasket, 3 - exhaust manifold bracket, 4 - guide tube and engine oil level dipstick assembly, 5 - engine suspension bracket, 6 - O-ring, 7 - fuel return hose connection, 8 - fuel inlet hose connection, 9 - O-ring, 10 - cylinder head bolt, 11 - cylinder head assembly, 12 - cylinder head gasket.

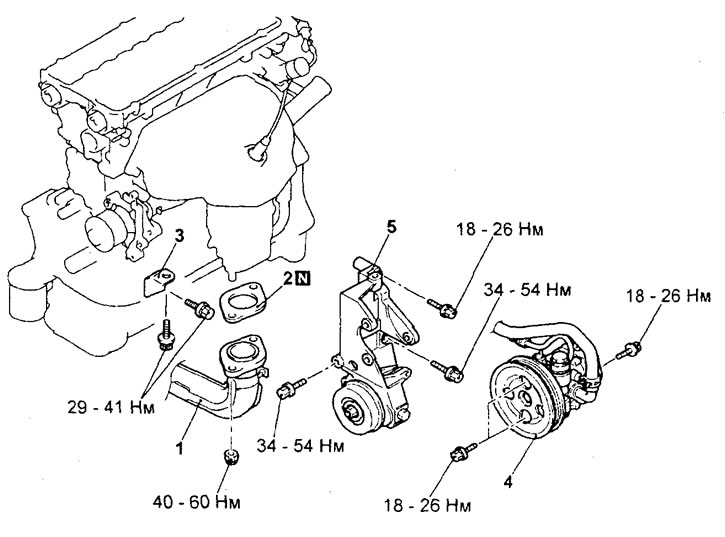

Replacing the cylinder head gasket (4G93 engine). 1 - exhaust pipe connection, 2 - gasket, 3 - exhaust manifold bracket, 4 - power steering pump, 5 - power steering pump bracket.

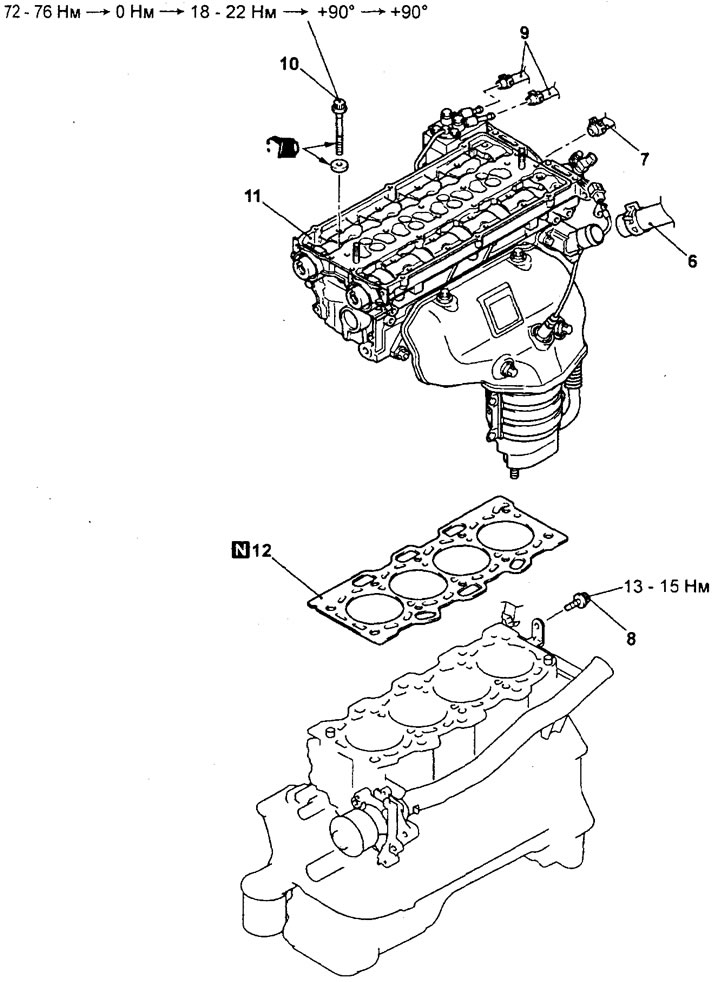

Replacing the cylinder head gasket (4G93 engine, continued). 6 - upper radiator hose connection, 7 - heater hose connection, 8 - cooling system inlet pipe retainer bolt, 9 - fuel return hose connection, 10 - cylinder head bolt, 11 - cylinder head assembly, 12 - head gasket cylinder block.

b) Loosen the camshaft pulley bolt.

3. (Engine 4G93) Removing the power steering pump assembly with bracket.

Remove the power steering pump assembly with bracket along with hoses connected to it.

Note: Tie the removed power steering pump assembly with bracket and hoses with wire and place it in a place where it will not interfere with the removal and installation of the cylinder head assembly.

4. Removing the cylinder head.

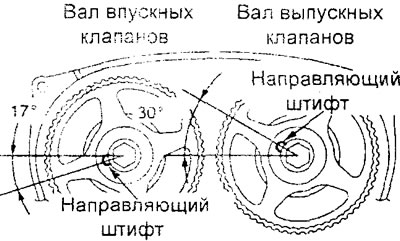

A) Install the camshafts so that their guide pins are in the position shown in the figure.

b) Using a special tool, loosen the mounting bolts in two or three steps (in the sequence shown in the figure), and then unscrew them, and then remove the cylinder head assembly.

Installation

Installation of details is made in an order, the return to removal.

Pay attention to the following operations when installing parts.

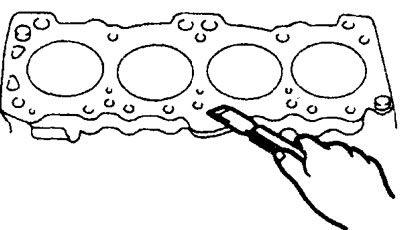

1. Installing the cylinder head gasket.

A) Using a special scraper, remove the remnants of the old cylinder head gasket from the cylinder block.

Caution: Be careful not to allow gasket material or other foreign matter to enter cylinders, cooling system passages, and lubrication passages.

b) Degrease the work surface under the gasket on the cylinder block.

V) Verify that the correct engine identification mark is on the new cylinder head gasket.

G) Lay the cylinder head gasket on the cylinder block.

Attention: since there is a possibility of improper installation of the cylinder head gasket, check the correct installation of the gasket before installing the cylinder head (coincidence of all holes on the gasket and the cylinder head). If the gasket is installed incorrectly, malfunctions may occur, for example, lack of oil ingress into the cylinder head.

2. Installing the cylinder head assembly.

A) Using a scraper, remove the remnants of the old cylinder head gasket from the cylinder head. Attention: be careful not to allow gasket material or other foreign particles to enter the cooling system channels and lubrication system channels.

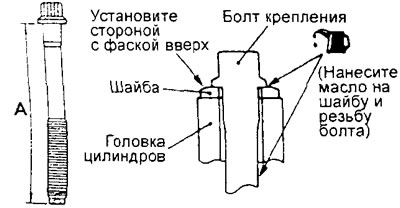

b) When installing the cylinder head bolts, the length of the bolts must be within the allowable value. If the length of the bolts is greater than the maximum allowable value, then the bolts must be replaced.

Maximum allowable value:

4G15 engine - no more than 103.2 mm

4G93 engine - no more than 96.4 mm

V) Lubricate the threads and washers of the cylinder head bolts with a small amount of clean engine oil.

G) Install the cylinder head bolt washers with the chamfered side up as shown.

d) Before installation, it is necessary to lubricate the upper surface of the washer and the thread of the bolt with a small amount of engine oil.

e) Tighten the cylinder head bolts using the angle tightening method in the following order (tightening is carried out in the sequence of numbers indicated in the figure):

Engine 4G15:

- (1) Tighten all bolts to 49±2 Nm in the order shown in the figure;

- (2) Completely loosen all bolts in the reverse order shown in the figure.

- (3) Tighten all bolts to 20±2 Nm in the order shown in the figure;

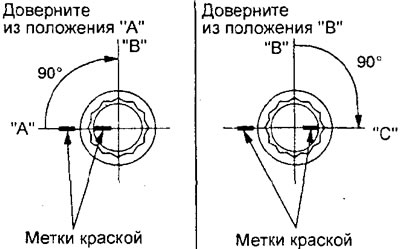

- (4) Tighten all bolts by 90° (1/4 turn, out of position "A" into position "IN") in the order shown in the figure;

- (5) Completely tighten all bolts by 90° (1/4 turn, out of position "IN" into position "WITH") in the order shown in the figure.

Engine 4G93:

- (1) Tighten all bolts to 74±2 Nm in the order shown on. drawing;

- (2) Completely loosen all bolts in the reverse order shown in the figure.

- (3) Tighten all bolts to 20 + 2 Nm in the order shown in the figure;

- (4) Tighten all bolts by 90° (1/4 turn, out of position "A" into position "IN") in the order shown in the figure;

- (5) Completely tighten all bolts by 90° (1/4 turn, out of position "IN" into position "WITH") in the order shown in the figure.

Note:

- After tightening, the marks on the bolts and the cylinder head must be in line ("WITH").

- If the cylinder head bolt is turned less than 90° (1/4 turn), then the tightening of the bolt will be insufficient (the reliability of the gas joint will not be ensured).

- If the cylinder head mounting bolt is tightened to a torque exceeding the nominal value, completely unscrew the mounting bolts and follow the bolt tightening procedure, starting from subparagraph "b".

3. (Engine 4G93) Installing the camshaft pulley.

A) Secure the camshaft pulley against rotation using a special fork holder and special bolts.

b) Wrap a bolt of fastening of a pulley of a camshaft the nominal moment.

Tightening torque - 89±9 Nm

4. (Engine 4G15) Installing the O-ring and fuel inlet hose.

A) Apply a small amount of clean engine oil to the fuel inlet hose O-ring.

Attention: do not allow engine oil to get inside the injection pump.

b) Be careful not to damage the o-ring when installing.

Turning the fuel hose flange from side to side, connect it to the injection pump. After connecting, check that the flange turns freely without binding.

V) If the fuel hose flange does not turn smoothly, the O-ring may be pinched. In this case, disconnect the fuel hose, check the condition of the gasket, replace it if necessary. Reconnect the fuel hose and check again for smooth rotation of the flange.

G) Tighten the hose mounting bolts to the specified torque.

Tightening torque - 5±1 Nm

5. Installing the fuel return hose.

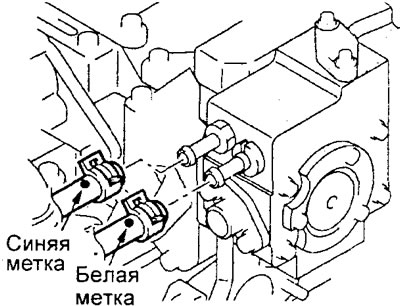

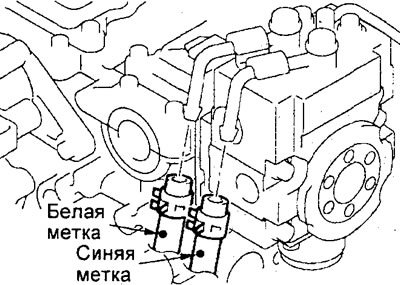

Install the fuel return hose with the identification mark facing as shown.

Engine 4G15.

Engine 4G93.

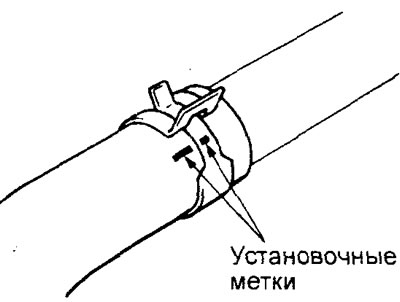

6. (Engine 4G93) Installing the upper radiator hose.

A) When connecting the upper radiator hose, put the hose on the branch pipe until it stops against the protrusion of the branch pipe, then tighten the clamp.

b) The hose clamp should always be installed in the position in which the clamp was previously installed. Therefore, before installing the clamp, align the alignment marks on the hose clamp and radiator hose, then connect the hose.

After completing the installation of the parts, perform the following operations:

- A) (Engine. 4G93) Install the EGR valve actuator.

- b) (Engine 4G15) Establish an adjusting lath of the generator.

- V) (Engine 4G93) Install the thermostat housing assembly.

- G) (Engine 4G15) Install the cooling system inlet pipe.

- d) Install the cover gaskets and cylinder head covers.

- e) Install the timing belt and accessory drive belts.

- and) Adjust the tension of the accessory drive belts (see the relevant section of the chapter "Maintenance and general inspection and adjustment procedures").

- h) Install the battery tray and battery.

- And) Install the air filter.

- To) Fill with coolant and engine oil.

- l) Install the engine crankcase guard.

- m) Perform High Pressure Fuel Line Bleeding Procedure (refer to the appropriate procedure for installing the injection pump in chapter "fuel injection system (GDI)").

- n) Check for fuel leaks.

- O) Install the decorative engine cover.