Engine Diagnostics

If, after starting the engine, an extraneous sound appears and does not disappear as the engine warms up ("clatter") from the hydraulic lifters, perform the following check.

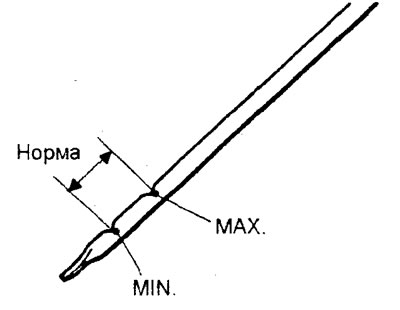

1. Check the oil level in the crankcase and its quality. Change or add the required amount of oil, if necessary.

A) If the amount of oil in the engine crankcase is insufficient, then air enters through the oil receiver strainer into the lubrication system channel.

b) If the amount of oil is more than normal, the oil foams excessively when the crankshaft rotates, and a large amount of air is mixed into the oil.

V) When oil ages (oil has lost its properties - degenerated), the air mixed into the oil cannot be easily separated from it, and its amount in the oil is constantly increasing.

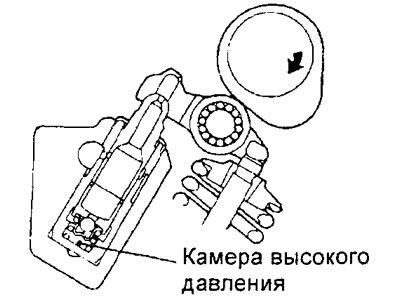

Attention: if there is a large amount of air in the oil due to one of the above reasons, and it enters the high pressure chamber of the hydraulic compensator, the air inside the hydraulic compensator is compressed when the valve is opened and the hydraulic compensator is also compressed (plunger "sag"), resulting in an abnormal noise when the valve closes. That is, the same thing happens when a too large thermal gap is set in the valve train drive by mistake. If you remove the air from the cavities of the hydraulic lifters, their work is restored.

2. Check if the noise appears immediately after starting the engine, and if there is noise, then check that it changes according to the change in engine speed.

Note:

- If the noise does not appear immediately after starting the engine, or if it does not change in accordance with the change in engine speed, then the malfunction is not caused by hydraulic lifters, look for another cause of the malfunction.

- Moreover, if the noise does not change in accordance with the change in engine speed, then the cause of the malfunction is probably not in the engine (in these cases, the hydraulic lifters work normally).

3. When the engine is idling, make sure that the noise level does not change when the engine load changes (for example, when switching the selector from the position "N" into position "D").

Note: If the noise level changes, the cause may be the impact of parts due to wear of the crankshaft bearings or connecting rod bearing shells (in such cases, hydraulic lifters work normally).

4. After warming up the engine, let it idle. Then check for extraneous noise. If the noise has decreased or disappeared, it is possible that the knock of the hydraulic lifters is caused by sediment (pollution) engine oil. In this case, change the engine oil, and then clean the hydraulic lifters (see section "Rocker arms and camshafts" in chapter "Engine - General Repair Procedures"). If this does not improve (those. extraneous noise has not disappeared), then go to paragraph "5".

5. If extraneous noise is present, perform the following check.

A) Stop the engine and let it cool down sufficiently.

b) Turn the engine crankshaft two full turns.

V) Perform a simple check of the hydraulic lifters.

- If, during a simple check of the hydraulic lifters, any rocker arms can be easily moved down, then replace the corresponding hydraulic lifters;

- If, after a simple check, all hydraulic lifters are found to be in good condition (those. if none of the rockers can be moved down without effort), then look for another cause of the malfunction.

Note: the condition of the hydraulic lifters can also be determined by checking their tightness (see section "Rocker arms and camshafts" in chapter "Engine - General Repair Procedures"), however, this requires their removal from the engine.

Attention: before installing a new hydraulic lifter, make sure that the air is completely removed from it.

6. Bleed air from hydraulic lifters (without removing them from the engine).

7. If the noise does not disappear even after bleeding the hydraulic lifters, then perform a simple check of the hydraulic lifters.

A) If, during a simple check of the hydraulic lifters, any of the rocker arms can easily be moved down, then replace the corresponding hydraulic lifters.

b) If two or more rocker arms can be easily moved down during the test, the cause may be a blockage in the oil passage leading to the cylinder head. Check that the oil passage is not blocked. Clear the channel if it is clogged. If clogging of the oil channel is not found, replace the hydraulic lifters.

V) If after a simple test it turns out that all hydraulic lifters are in good condition (if none of the rockers can be easily moved down), then look for another cause of the malfunction.

Note: the condition of the hydraulic lifters can also be determined by checking their tightness (see section "Rocker arms and camshafts" in chapter "Engine - General Repair Procedures").

Attention: before installing a new hydraulic lifter, make sure that the air is completely removed from it.

8. Start the engine and check that the extraneous noise has disappeared. If necessary, bleed the air from the hydraulic lifters.

Removing air from hydraulic lifters without removing them from the engine

Note: If any of the above situations occurs, extraneous noise can be eliminated by removing air from the hydraulic lifters.

- If the vehicle has been parked on a slope for a long period of time, the amount of oil in the hydraulic lifters will decrease and air may enter the high pressure chamber of the hydraulic lifters.

- If the car has not been used for a long time, the oil could also leak out of the oil channels, so it takes some time to fill the cavities of the hydraulic lifters with oil and to remove air from them.

1. Check the engine oil level in the crankcase and its quality, replace or add the required amount if necessary.

2. Let the engine idle for 1-3 minutes to allow it to warm up.

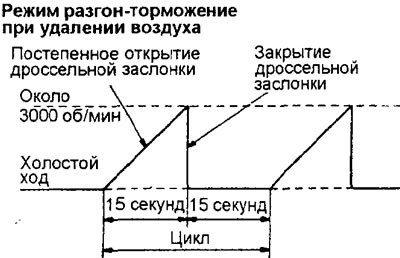

3. Without putting a load on the motor, perform the motor acceleration-deceleration procedure shown in the figure several times until the abnormal noise disappears (usually the noise disappears after 10-30 cycles, but if even after 30 cycles the noise does not disappear, then the reason for it is not the presence of air in the hydraulic lifters).

4. After the noise disappears, repeat the same acceleration-deceleration procedure about 5 more times.

5. Let the engine idle for another 1-3 minutes to make sure there is no abnormal noise.