Cylinder firing order: 1-3-4-2.

The cylinder block is made of cast iron, the cylinder head and the coolant pump housing are made of aluminum alloy.

The forged steel crankshaft is supported by five bearings. The bearing caps are integrated into the crankshaft bed to increase the rigidity of the cylinder block.

The piston is cast from a special aluminum alloy and is connected by a floating piston pin to the connecting rod.

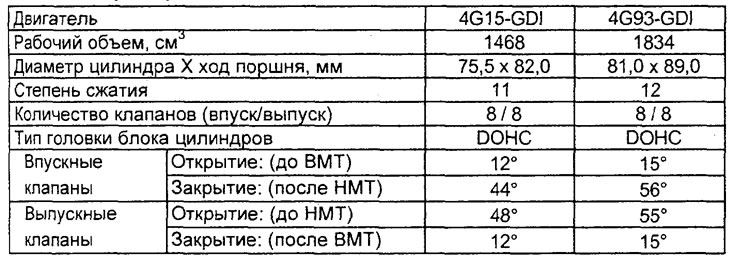

Table. Characteristics of engines.

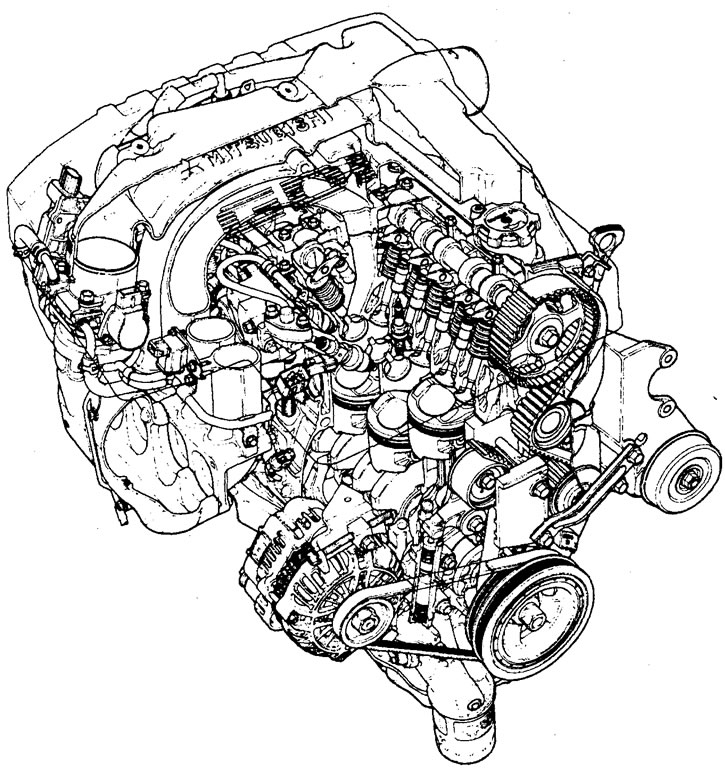

General view of the 4G93-GDI engine.

For the GDI engine, a specially shaped recess is made in the piston crown, with the help of which the air-fuel mixture is directed to the spark plug area.

Piston rings are cast iron. The first ring has a barrel-shaped outer surface, the second ring has a conical outer surface with a bevel. The oil scraper ring is composite, scraper type with a spring expander.

In the cylinder head are tent-type combustion chambers. The inlet and outlet valves are made of heat resistant steel. To adjust the clearance in the valve drive, hydraulic compensators are installed. Rocker arms with rollers are cast from aluminum alloy and have a wear-resistant bearing surface in contact with the camshaft cam.

Each cast camshaft is supported by six bearings and secured by a camshaft bearing cap assembly.

The camshaft position sensor rotor is mounted on the exhaust valve shaft. The injection pump is driven from the intake valve shaft.

The camshafts are driven from the crankshaft by a toothed belt, the belt tension in the 4G93 engine is regulated by an automatic tensioner, and in the 4G15 engine by a spring tensioner.