Removing

− Before starting to remove parts, carry out the following operations:

- A) Remove the engine crankcase guard.

- b) Drain the engine oil.

- V) Remove a reception pipe of system of release.

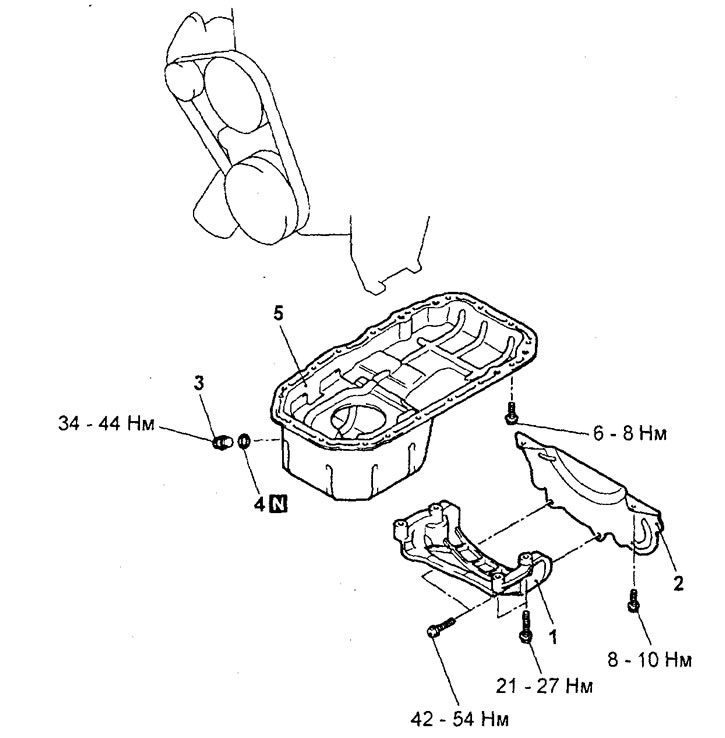

− Removal of parts is carried out in the order of numbers indicated in the figure "Removing the oil pan".

Removing the oil pan (4G15 engine). 1 - gearbox mounting bracket, 2 - gearbox housing, 3 - drain plug, 4 - gasket, 5 - oil pan.

Removing the oil pan (4G93 engine).1 - drain plug, 2 - gasket, 3 - bottom of oil pan, 4 - oil pan cover, 5 - top of oil pan, 6 - baffle plate.

− When removing parts, pay attention to the following operations:

1. (Engine 4G15) Removing the oil pan.

A) Loosen the oil pan mounting bolts.

b) Insert the special oil pan remover between the oil pan and the cylinder block.

V) Move the special tool along the edge of the oil pan, hitting it at an angle to separate the pan.

Caution: Using a screwdriver or chisel instead of a dedicated oil pan remover may damage the gasket surface and cause oil leakage.

G) Remove the oil pan.

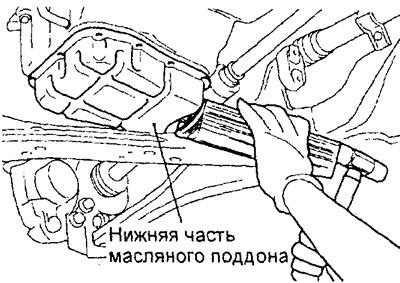

2. (Engine 4G93) Removing the lower part of the oil pan.

A) Loosen the oil pan bottom bolts.

b) Place a block of wood on the side of the bottom of the oil pan as shown in the illustration, and hit the block with a plastic mallet to separate the bottom of the oil pan from the top.

Caution: Using an oil pan puller can damage the upper part of the oil pan, which is made of aluminum.

4. (Engine 4G93) Removing the upper part of the oil pan.

A) Loosen the upper oil pan bolts.

b) Insert a flat-blade screwdriver between the top of the oil pan and the cylinder block as shown in the illustration, and pry off the top of the oil pan.

Caution: Using an oil pan puller can damage the aluminum oil pan.

Examination

1. Check the oil pan for cracks.

2. Check the sealant or gasket surface on the oil pan for damage or deformation. Fix it if possible.

3. Check the oil receiver for damage, clogging or damage to the screen and tube.

Installation

− Installation of parts is carried out in the reverse order of removal.

− When installing parts, pay attention to the following operations:

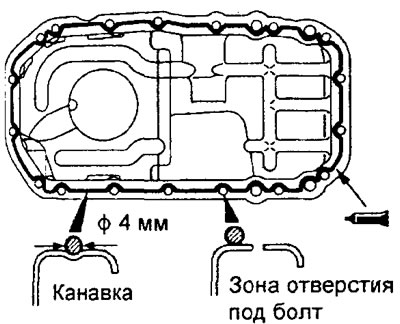

1. (Engine 4G 15) Oil pan installation.

A) Remove the old sealant from the mating surfaces of the cylinder block and oil pan.

b) Degrease the sealant surface on the oil pan and mating surface on the cylinder block.

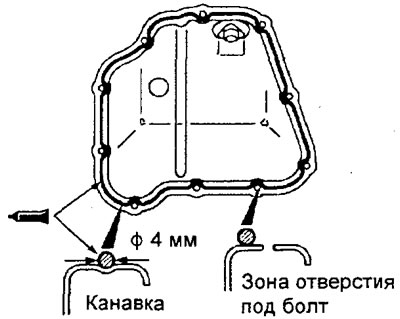

V) Apply sealant to the surface of the oil pan as shown in the illustration. The sealant should be applied in a continuous bead with a diameter of approximately 4 mm.

Sealant MITSUBISHI GENUINE Part No. MD970389, Three Bond 1207F or equivalent

Note: The installation of the oil pan must be completed within the time specified in the instructions for use of the sealant.

G) Install and tighten the oil pan bolts to specification. Tighten the oil pan bolts gradually, in several steps, in a diagonal sequence.

Tightening torque - 9±3 N.m

Attention: after installing the oil pan, wait at least an hour before starting the engine.

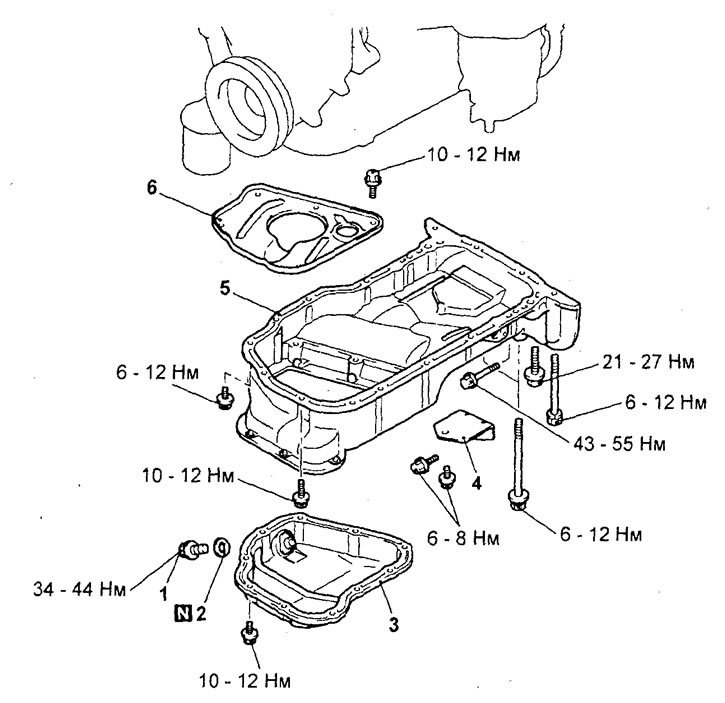

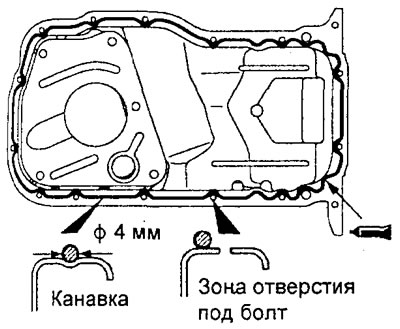

2. (Engine 4G93) Installing the upper part of the oil pan.

A) Clean the mating surfaces of the cylinder block and oil pan flange from the remnants of the old sealant. After cleaning, degrease surfaces to be sealed.

b) Apply sealant in a continuous bead of approximately 4 mm in diameter around the entire flange of the top of the oil pan as shown in the illustration.

Sealant MITSUBISHI GENUINE Part No. MD970389, Three Bond 1207F or equivalent

Attention: do not allow the sealant to be squeezed out in the area of the sump on the side of the gearbox.

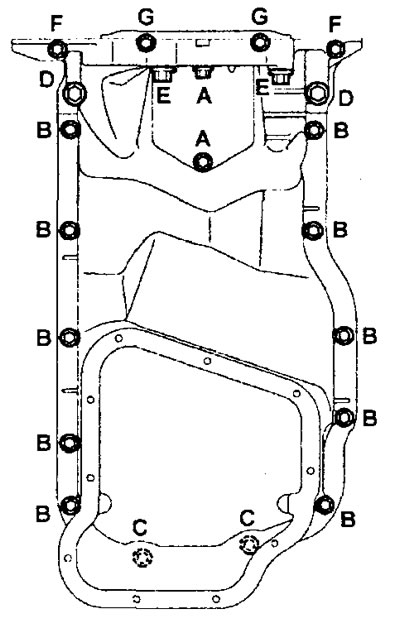

V) Install and secure the oil pan within 15 minutes of applying the sealant. Tighten the oil pan bolts gradually, in several steps, in a diagonal sequence.

Attention:

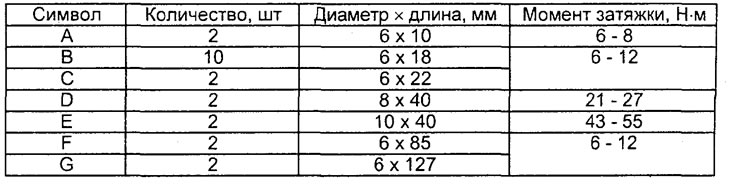

- Be careful, the length of the bolts and tightening torques differ depending on the installation location, do not confuse the location of the bolts (see table "Dimensions and tightening torques of the bolts for fastening the upper part of the oil pan").

- After installing the oil pan, wait at least one hour before starting the engine.

3. (Engine 4G93) Installing the lower part of the oil pan.

A) Clean the mating surfaces of the flanges of the upper and lower parts of the oil pan from the remnants of the old sealant. After cleaning, degrease surfaces to be sealed.

b) Apply sealant in a continuous bead of approximately 4 mm in diameter around the entire flange of the bottom of the oil pan as shown in the illustration.

Sealant MITSUBISHI GENUINE Part No. MD970389, Three Bond 1207F or equivalent

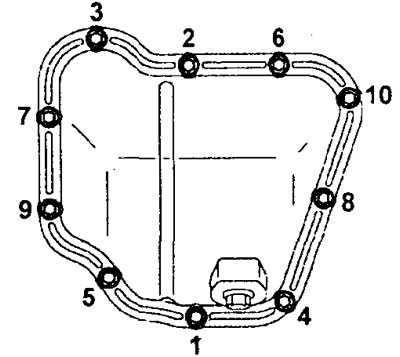

V) Install and secure the bottom of the oil pan within 15 minutes of applying the sealant. Tighten the oil pan bolts in the sequence shown in the figure.

Tightening torques - 10-12 N.m

Attention: after installing the oil pan, wait at least an hour before starting the engine.

4. Installing the drain plug gasket. Install the new drain plug O-ring in the direction shown in the illustration.

Note: Incorrect gasket installation can cause engine oil leaks.

− After completing the installation of the parts, perform the following operations:

- A) Install the exhaust pipe.

- b) Fill with engine oil.

- V) Install the engine crankcase guard.

Table. Dimensions and tightening torques of the bolts for fastening the upper part of the oil pan (only 4G93 engine).