2. Check the correct installation of the timing belt.

Attention:

- Do not bend, twist or stretch the timing belt.

- Do not allow the timing belt to come into contact with oil, coolant and water.

3. The belt must be carefully checked. If the following obvious defects are found, replace the belt with a new one.

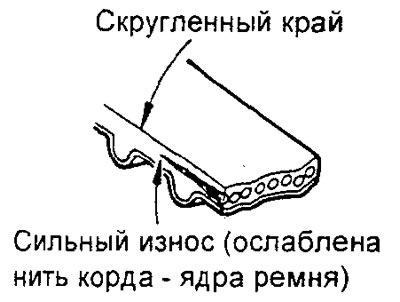

A) Hardened rubber on the back of the belt: shiny, inelastic, and so hard that a fingernail doesn't leave a mark on it when pressed.

b) Cracked rubber on the back of the belt (due to overheating).

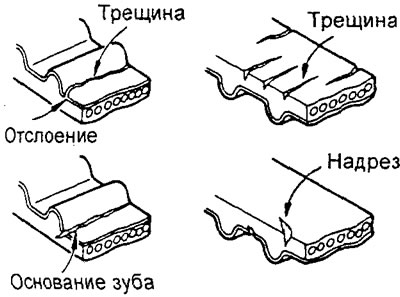

V) Cracks or delamination of the belt cord (due to improper adjustment of the belt tension).

G) Cracks at the base of the tooth.

Note: Defects described in subparagraphs "G"-"e", are caused by poor alignment of the pulleys or difficult rotation of the accessories.

d) Notch on the side of the belt.

e) Heavy side wear. Note: A normal belt should have clearly pointed sides, similar to those cut with a knife.

and) Severe tooth wear (due to incorrect belt tension).

Note:

- At the initial stage of belt wear, the tissue at the root of the tooth on the working side is worn out (fleecy fibers of the fabric, the rubber layer has disappeared, the color has changed to white, the fuzzy structure of the fabric).

- At the last stage of belt wear, the fabric at the root of the tooth on the working side is finally worn out with the rubber layer exposed (tooth width reduced).

h) Absence of a tooth.