2. Before starting the test procedure, prepare the vehicle (see section "Checking the idle speed").

3. (MPI motors) Disconnect high voltage spark plug wires.

4. Remove the ignition coils and remove all spark plugs.

5. Disconnect the crankshaft position sensor connector.

Note: This operation is necessary to prevent the ECM from issuing fuel injection and ignition commands.

Engine 4G15-GDI.

Engine 4G93-GDI.

Engine 4G15-MPI.

Engine 4G93-MPI.

6. Close the holes for the spark plugs with a clean rag and, after cranking the crankshaft with a starter, check that there are no foreign particles on the rags.

Attention:

- Keep clear of the spark plug holes while cranking the crankshaft with the starter.

- If during the measurement of compression in the cylinder (as a result of cracks) If coolant, oil, fuel, etc. gets in, these substances will heat up and will be ejected under pressure from the spark plug hole, which is a dangerous phenomenon.

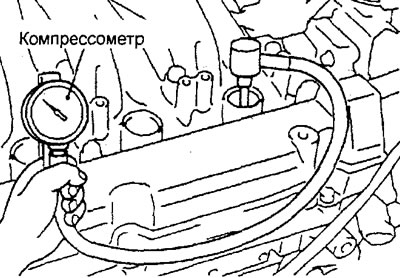

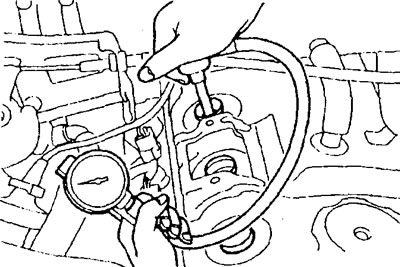

7. Install a compression gauge in the spark plug hole.

GDI engines.

MPI engine.

8. Turn the engine crankshaft with the starter at full throttle and measure the compression.

Compression:

Engine 4G15-GDI:

- nominal - 1755 kPa

- minimum allowable - 1275 kPa

- rotational speed when scrolling with a starter - 250 rpm

Engine 4G93-GDI:

- nominal - 1720 kPa

- minimum allowable - 1334 kPa

- rotational speed when scrolling with a starter - 300 rpm

Engine 4G15-MPI:

- nominal - 1608 kPa

- minimum allowable - 1275 kPa

- rotational speed when scrolling with a starter - 300 rpm

Engine 4G93-MPI:

- nominal - 1226 kPa

- minimum allowable - 1030 kPa

- rotational speed when scrolling with a starter - 300 rpm

Note: Compression values shown are valid only at the specified engine speed.

9. Measure a compression in all cylinders and check up that a difference of a compression between cylinders is less than limit admissible value. Maximum permissible value is not more than 98 kPa

10. If in any cylinder the compression is below the minimum allowable value or the difference in compression between the cylinders exceeds the maximum allowable value, then pour a little engine oil into the spark plug hole of this cylinder and repeat the measurements point by point "8" And "9".

Attention:

- If, after filling with oil, the compression has increased, then the causes of the malfunction are wear or damage to the piston ring and / or cylinder mirror.

- If the compression does not increase after filling with oil, then the causes are burnt or damaged valve seats, or gas leaks (pressure) through the cylinder head gasket.

11. Connect the harness connector to the crankshaft position sensor.

12. Install spark plugs and ignition coils.

13. (MPI motors) Connect high voltage spark plug wires to spark plugs and ignition coils.

14. Delete the trouble codes resulting from the disconnection of the crankshaft position sensor connector from the memory of the electronic engine control unit (see the relevant section in chapter "fuel injection system").