Checking drive belts

1. Check the drive belt for damage and excessive wear and make sure it is properly seated in the pulley grooves. If the belt "squeals" or slips, check the condition of the contact surfaces of the pulley and the belt tension. If defects are found, replace the drive belt.

Caution: Do not apply oil or grease to drive belts.

Note: it is not allowed to peel off the rubber from the cord on the inner (from the side of the ridges) and the outer surfaces of the belt, exposed or damaged cord, peeling of the ridges from the rubber base, the presence of cracks, peeling or wear on the sides of the belt and the ridges of the belt.

2. Check that the belt does not slip off the tensioner roller. Replace tensioner if necessary.

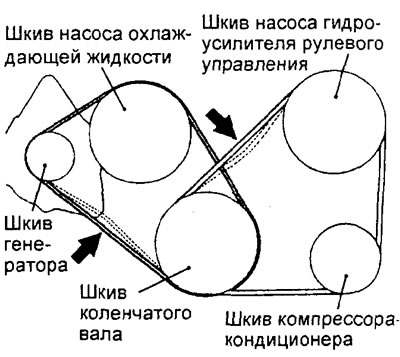

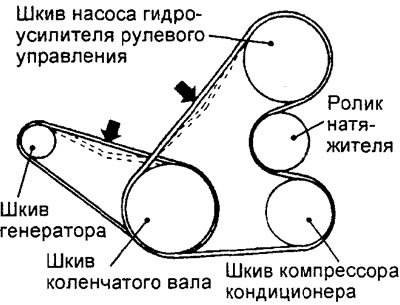

3. Check the belt deflection by pressing in the center of the belt span between the pulleys with a force of 100 N as shown in the figure.

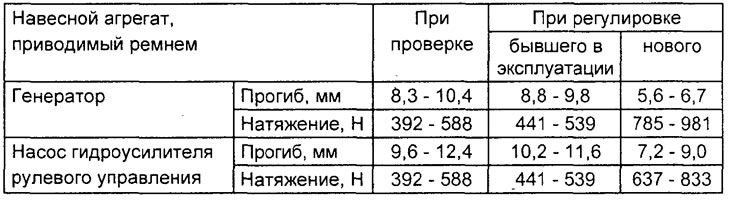

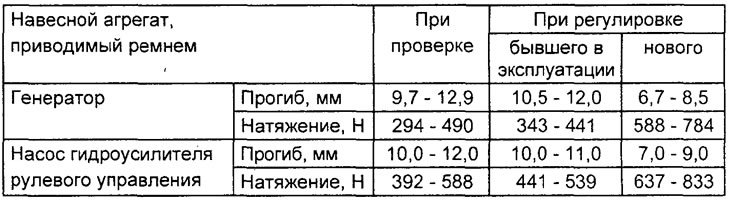

4. Adjust the deflection of the belt if it does not correspond to the nominal value given in the table "Checking and adjusting the drive belts of mounted units".

Note:

- Term "used belt" refers to a belt that has been in operation for more than 5 minutes.

- After installing the belt, start the engine and let it run for 5 minutes, and then check the belt tension again.

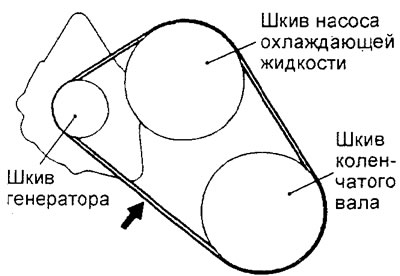

Engine 4G15.

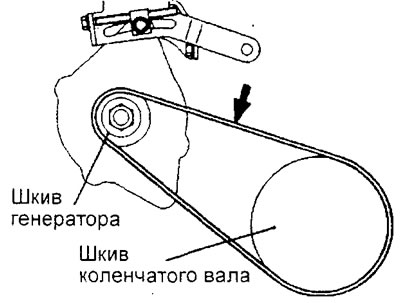

Engine 4G93.

Alternator Drive Belt Tension Adjustment

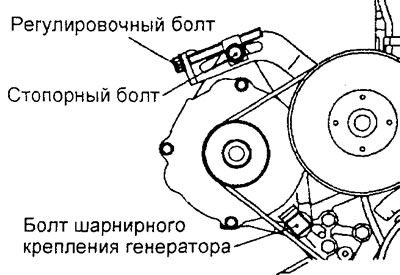

1. Loosen the alternator pivot bolt nut.

Table. Checking and adjusting the drive belts of mounted units of the 4G15 engine.

Table. Checking and adjusting the drive belts of mounted units of the 4G93 engine.

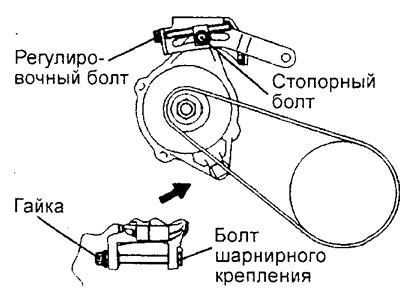

2. Loosen the locking bolt on the adjuster bracket.

Engine 4G15.

Engine 4G93.

3. Turning the adjusting bolt, adjust the tension and deflection of the belt to the nominal values (see table "Checking and adjusting the drive belts of mounted units").

4. Tighten the lock bolt.

Tightening torque - 23±2 N·m

5. Tighten the alternator pivot bolt nut.

Tightening torque - 44 + 10 N.m

6. Tighten the adjusting bolt.

Tightening torque - 5 N.m

7. Turn the engine crankshaft with the starter one or more times, and then check the belt deflection.

Engine 4G15.

Engine 4G93.

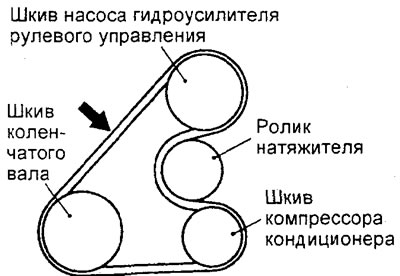

Adjustment of a tension of a belt of a drive of the pump of the hydraulic booster of a steering and the conditioner compressor

Engine 4G93

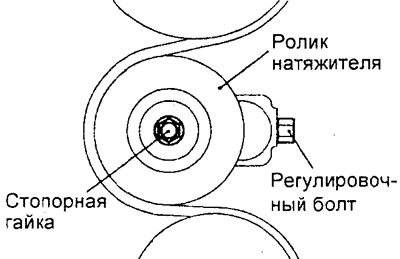

1. Loosen the tensioner roller lock nut.

2. Turn the adjusting bolt on the tensioner bracket to adjust the tension and deflection of the belt so that it corresponds to the nominal value (see table "Checking and adjusting the drive belts of mounted units").

3. Tighten the tensioner roller lock nut.

Tightening torque - 26±4 N.m

4. Turn the engine crankshaft one revolution or more in the normal direction of rotation (clockwise), then - check the deflection of the drive belt.

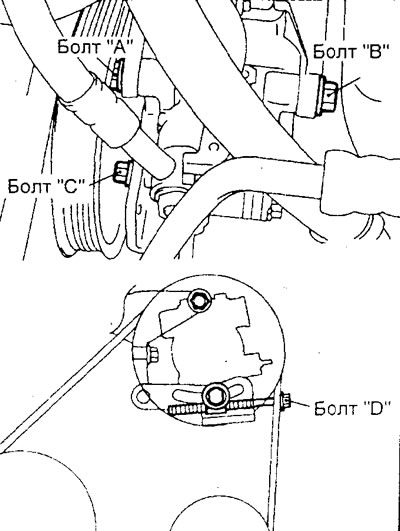

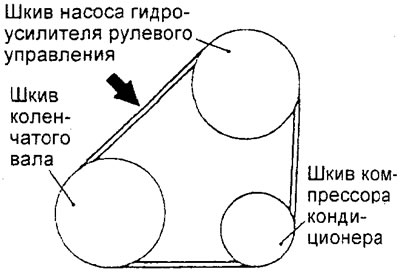

Engine 4G15

1. Loosen the bolts "A", "IN" And "WITH" power steering pump shown in the figure.

2. Turning the adjusting bolt "D" on the tensioner bracket, adjust the tension and deflection of the belt so that it corresponds to the nominal value (see table "Checking and adjusting the drive belts of mounted units").

3. Tighten the bolts "A", "IN" And "WITH" power steering pump rated torque.

Tightening torque - 40±5 N.m

4. Turn the engine crankshaft one revolution or more in the normal direction of rotation (clockwise), then check the deflection of the drive belt.