Reading and clearing trouble codes

Reading and deleting fault codes of the air conditioning system is carried out only with the help of a tester.

The procedure for reading codes using a tester is given in chapter "fuel injection system (MPI)".

Note: description of fault codes is given in the table "Air Conditioning Fault Codes"

Checking the electronic control unit for air conditioning

Disconnect the connector from the A/C ECM and check the connector on the wiring harness side according to the table "Checking the voltage at the terminals of the electronic control unit for air conditioning".

Caution: To avoid damage to the servo, the duration of the test should not exceed 40 seconds.

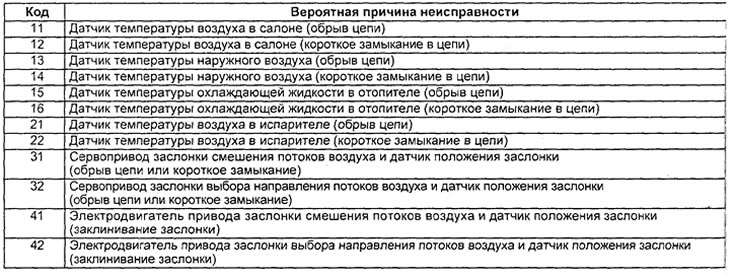

Table. Codes of malfunctions of the air conditioning system.

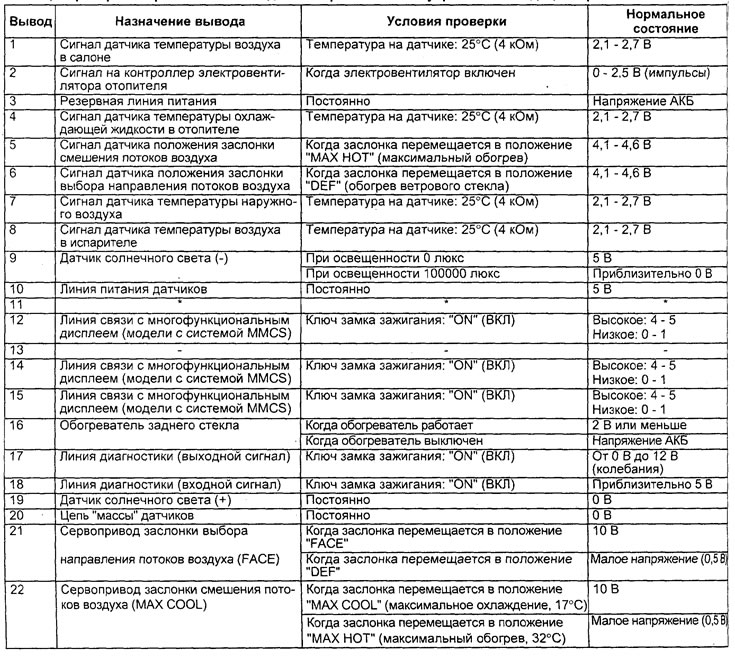

Connectors for the electronic control unit for air conditioning.

Table. Checking the voltage at the terminals of the electronic control unit for the air conditioner.

Checking System Components

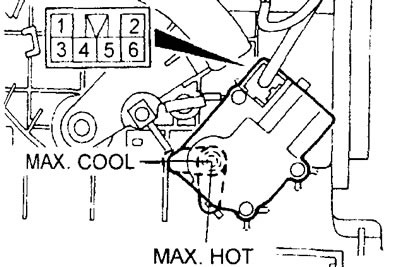

1. Checking the air mixing damper servo.

Bring the power (battery voltage) to conclusions "1" (-) And "3" (+) motor connector and check that the air intake selector flap lever moves to the position "MAX. COOL". Also check that, the air intake mode selector lever moves in the reverse direction (towards position "MAX. NOT") when changing the polarity of the power connection.

Attention: turn off the power when the damper is in the position "MAX. COOL" or "MAX. NOT".

2. Checking the air mixing damper servo position sensor.

Connect tester between leads "2" And "5", as well as between the conclusions "5" And "6" and check that the resistance changes gradually as the damper is moved to the position "MAX. COOL" or "MAX. NOT".

Rated value - 0.65 - 5.35 kOhm

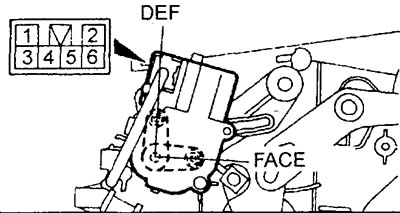

3. Checking the damper actuator for selecting the direction of air flow.

Bring the power (battery voltage) to conclusions "1" (+) And "3" (-) motor connector and check that the air intake selector flap lever moves to the position "DEF". Also check that the air intake mode selector lever moves in the opposite direction (towards position "FACE ") when changing the polarity of the power connection.

Attention: turn off the power after the damper has moved to the position "DEF" or "FACE".

4. Checking the position sensor of the servomotor of the damper for selecting the direction of air flow.

Connect tester between leads "2" And "5", as well as between the conclusions "5" And "6" and check that the resistance changes gradually as the damper is moved to the position "DEF" or "FACE".

Rated values - 0.65 - 5.35 kOhm

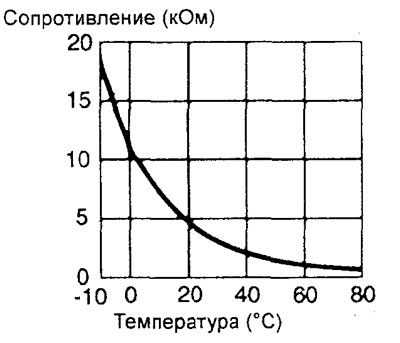

5. Checking the coolant temperature sensor in the evaporator.

Measure the resistance between the sensor leads for two or more temperatures. The resistance between the sensor leads should differ slightly from the value indicated on the graph.

Note: when checking, the air temperature should not go beyond the range in which the curve on the graph is located.

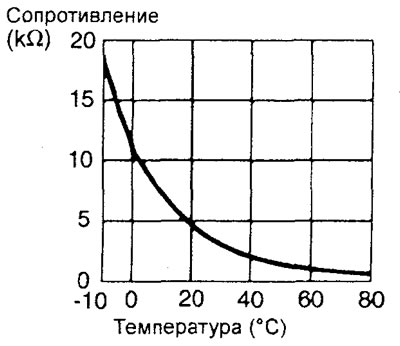

6. Checking the cabin air temperature sensor.

Measure the resistance between the sensor leads for two or more temperatures. The resistance to the method by the sensor outputs should differ slightly from the value indicated on the graph.

Note: when checking, the air temperature should not go beyond the range in which the curve on the graph is located.

7. Checking the Sunlight Sensor. If the heater fan speed decreases when the sensing side of the sunlight sensor is covered with your hand and the air conditioner is operating in "AUTO", then the sunlight sensor is OK. If the heater fan speed does not change, replace the sunlight sensor.

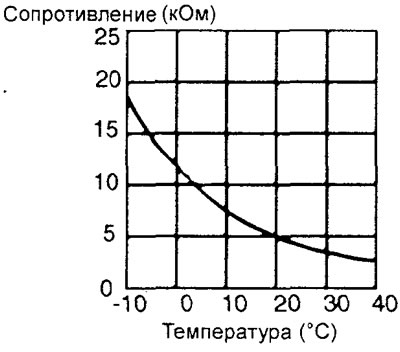

8. Checking the evaporator air temperature sensor.

Measure the resistance between the sensor leads for two or more temperatures. The resistance between the sensor leads should differ slightly from the value indicated on the graph.

Note: when checking, the air temperature should not go beyond the range in which the curve on the graph is located.

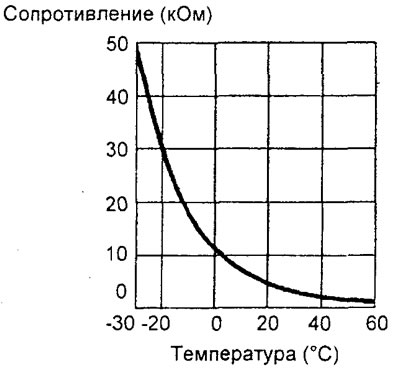

9. Checking the outdoor temperature sensor.

Measure the resistance between the sensor leads for two or more temperatures. The resistance between the sensor leads should differ slightly from the value indicated on the graph.

Note: when checking, the air temperature should not go beyond the range in which the curve on the graph is located.

Disassembly and assembly of the heater unit

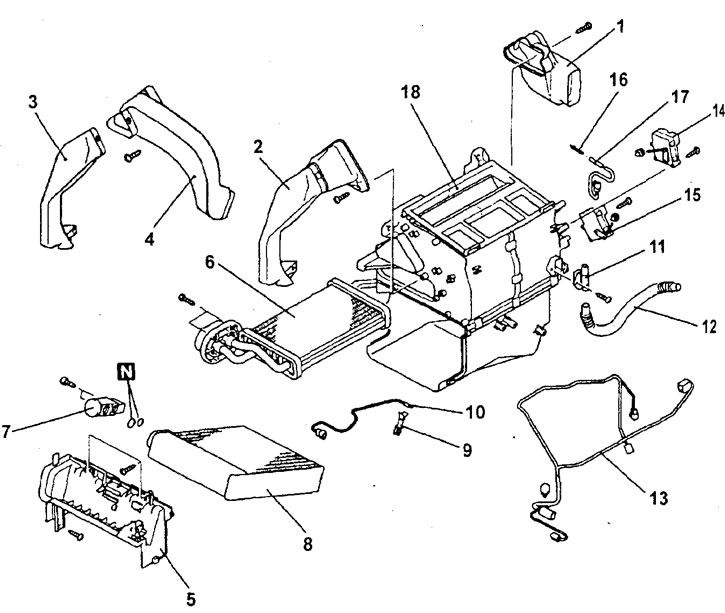

Disassembly of parts is carried out in the order of the numbers indicated in the figure "Dismantling the heater block".

Dismantling the heater block (automatic air conditioner). 1 - air supply duct to the leg area (right), 2 - air duct for air supply to the leg area (left), 3 - additional air duct for air supply to the leg area (left), 4 - additional rear air duct, 5 - evaporator cover, 6 - heater radiator, 7 - expansion valve, 8 - evaporator, 9 - evaporator air temperature sensor retainer, 10 - evaporator air temperature sensor, 11 - aspirator, 12 - bypass air hose, 13 - wiring harness, 14 - air intake mode selection damper servo drive, 15 - air mixing damper servo drive, 16 - evaporator coolant temperature sensor retainer, 17 - evaporator coolant temperature sensor, 18 - heater block.

The parts are assembled in the reverse order of removal.

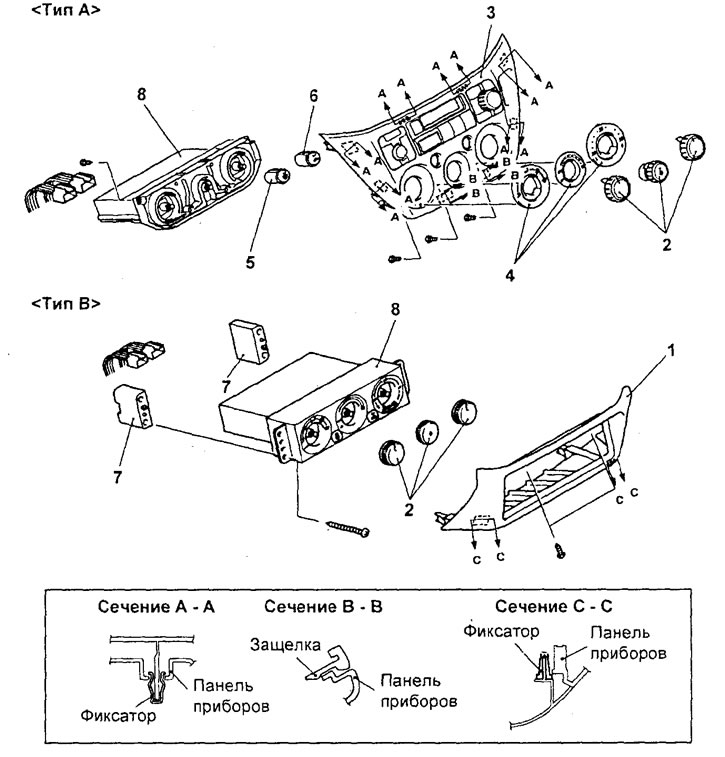

Removal and installation of the control panel of a heater and the conditioner

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing the heater and air conditioning control panel assembly".

Removing the heater and air conditioning control panel assembly (automatic air conditioner). 1 - additional glove box in the lower part of the central instrument panel trim, 2 - air conditioning control switch knobs assembly, 3 - heater and air conditioning control panel trim, 4 - heater and air conditioning control panel switch trims, 5 - rear window defroster switch knob, 6 - air intake mode selection switch knob, 7 - heater and air conditioning control panel bracket, 8 - heater and air conditioning control panel assembly (air conditioning electronic control unit).

Installation of details is made in an order, the return to removal.

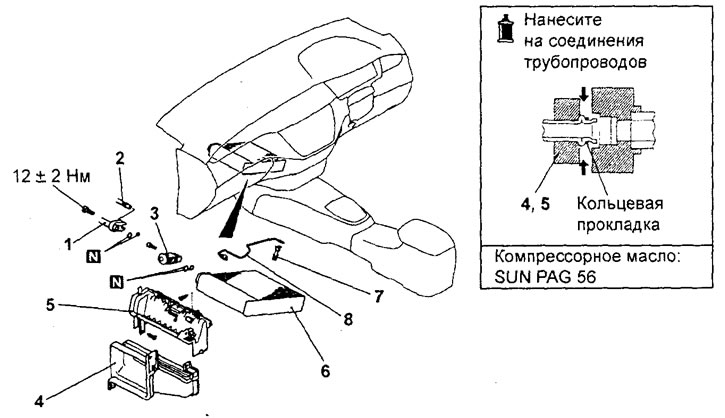

Removal and installation of the evaporator assembly

Before you start removing parts, do the following:

- A) Extract the refrigerant from the air conditioning system.

- b) Remove the engine and CVT control unit.

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing the evaporator assembly (automatic air conditioner) ".

Removing the evaporator assembly (automatic air conditioner). 1 - low pressure hose connection, 2 - tube connection "IN" high pressure, 3 - expansion valve, 4 - intermediate air duct, 5 - evaporator cover, 6 - evaporator, 7 - evaporator air temperature sensor retainer, 8 - evaporator air temperature sensor.

When removing parts, pay attention to the following operations:

1. Removing the low pressure hose, tube "IN" high pressure and expansion valve.

Cover the disconnected evaporator tubes and fittings to prevent moisture, dust and other contaminants from entering.

Attention: the hoses must be tight, otherwise the compressor oil and the dryer receiver may be saturated with water vapor from the atmosphere. Do not use porous material to cover pipes and fittings.

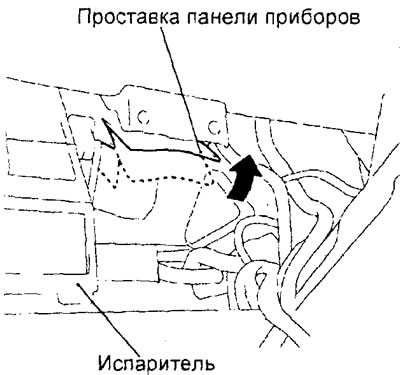

2. Removing the evaporator.

For easy removal of the evaporator, it is necessary to cut the instrument panel spacer as shown in the figure.

Attention: do not cut through the instrument panel spacer.

* Install parts in the reverse order of removal.

Note: when replacing parts, it is necessary to add compressor oil to the system (see section "Work with the air conditioning system").

After completing the installation of the parts, perform the following operations:

- A) Install the engine and CVT control unit.

- b) Charge the system with coolant.

Removal and installation of servo dampers and electric motor of the heater fan

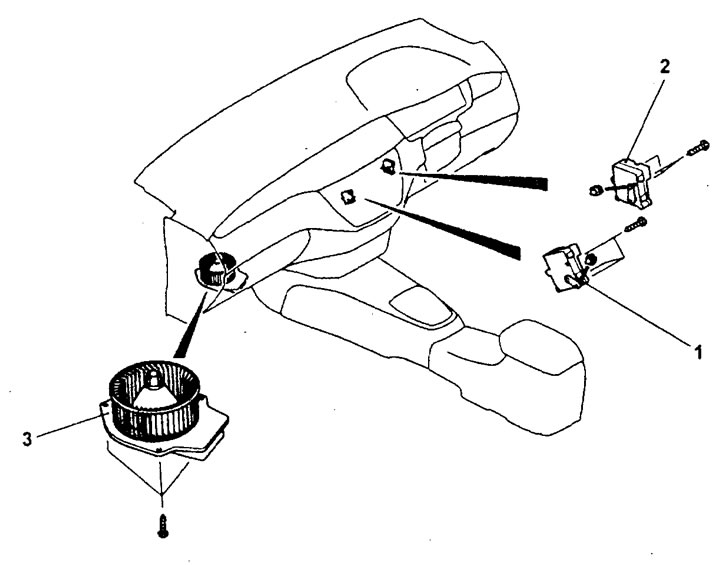

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing the damper servomotors and the heater fan motor".

Removing the damper servomotors and the heater fan motor (automatic air conditioner). 1 - air mixing damper servo and servo position sensor, 2 - damper servo for selecting the air intake mode and servo position sensor, 3 - heater fan motor.

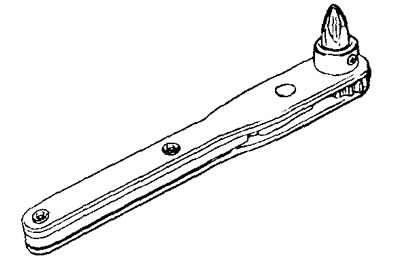

When removing parts, pay attention to the operation of removing the heater fan motor.

Remove the heater fan motor using the special tool shown in the figure.

Installation of details is made in an order, the return to removal.

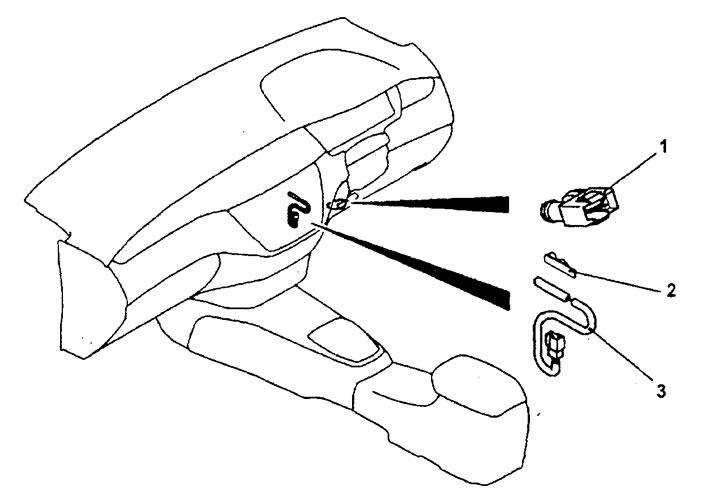

Removal and installation of sensors

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing sensors".

Removing sensors (automatic air conditioner).

1 - interior air temperature sensor (remove the lower distribution duct (in the leg area on the passenger side),

2 - latch,

3 - coolant temperature sensor in the heater.

Installation of details is made in an order, the return to removal.