Removal and installation

Note: checking the compressor magnetic clutch is given in the section "Basic Checks".

− Before starting to remove parts, pump out the refrigerant from the air conditioning system.

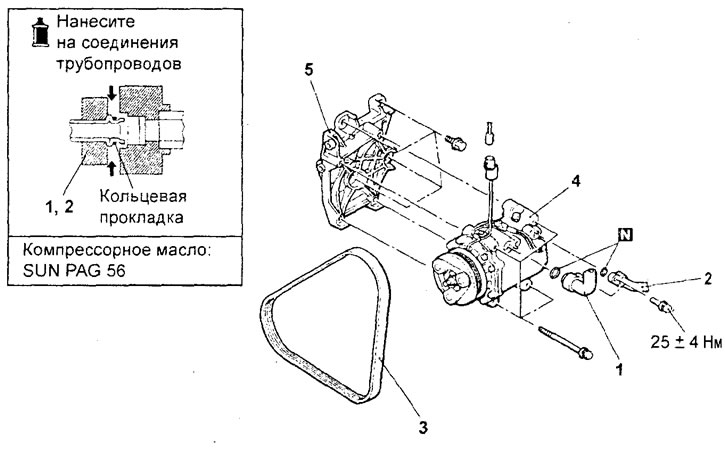

− Removal of parts is carried out in the order of numbers indicated in the figure "Removing the compressor and accessory drive belt".

Removing the compressor and accessory drive belt. 1 - low pressure hose connection (leading to the compressor), 2 - high pressure hose connection (diverting), 3 - attachment drive belt, 4 - compressor, 5 - compressor mounting bracket.

− When removing parts, pay attention to the following operations:

1. Disconnect the low pressure hose and high pressure hose.

Cover disconnected compressor hoses and fittings to prevent moisture, dust and other contaminants from entering.

Attention: the hoses must be tight, otherwise the compressor oil and the dryer receiver may be saturated with water vapor from the atmosphere. Do not use porous material to cover pipes and fittings.

2. Removing the compressor drive belt.

Removing the compressor drive belt, see chapter "Engine - Mechanical".

3. Removing the compressor.

Attention: be careful when removing the compressor, do not let the compressor oil leak.

− Installation of parts is carried out in the reverse order of removal.

− When installing the parts, pay attention to the installation operation of the compressor.

If a new compressor is being installed, pre-adjust the amount of oil filled into it as indicated below, and then install the compressor (those. maintain oil balance in the air conditioning system).

A) Measure the amount of oil [X ml] that was in the removed compressor.

b) Drain the amount of oil [Y ml] calculated from the formula below from the new compressor, and then install the new compressor in place.

Oil volume in the new compressor - 140 ml - X ml = Y ml

Note: [Y ml] refers to the amount of oil left in the pipes, condenser, evaporator, hoses, etc.

− After completing the installation of the parts, perform the following operations:

- A) Charge the air conditioning system with refrigerant.

- b) Adjust the tension of the compressor drive belt.

Disassembly and assembly of the electromagnetic clutch of the compressor

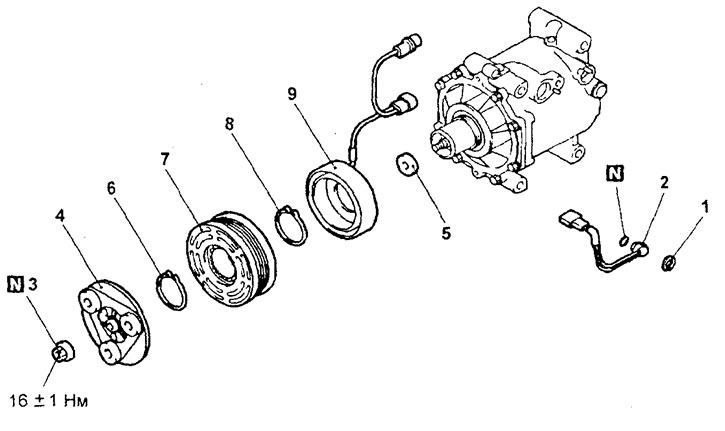

Removal of parts is carried out in the order of the numbers indicated in the figure " Disassembly of the electromagnetic clutch of the compressor".

Dismantling the electromagnetic clutch of the compressor. 1 - retaining ring, 2 - sensor-switch for refrigerant temperature (during installation, check the air gap in the magnetic clutch), 3 - self-locking nut, 4 - armature disk, 5 - washer, 6 - retaining ring, 7 - rotor, 8 - retaining ring, 9 - coupling winding.

- When removing parts, pay attention to the operation of loosening the self-locking nut of the compressor pulley.

Installation of details is made in an order, the return to removal.

− Pay attention to the following operations when installing parts.

1. Installation of the winding of the electromagnetic clutch.

When installing the clutch coil onto the compressor housing, align the protrusion of the clutch coil with the hole in the compressor housing.

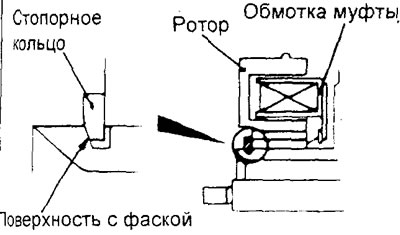

2. Installing the retaining ring.

Install the circlip so that the chamfered end is on the outside, as shown in the figure.

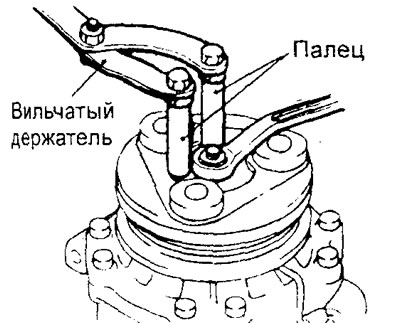

3. Installing the self-locking nut of the compressor pulley.

Using the special tool, fix the magnetic clutch and tighten the compressor pulley nut.

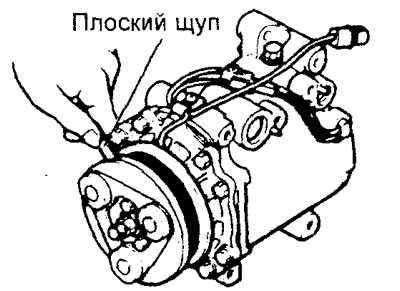

4. Checking the air gap in the electromagnetic clutch.

Check if the air gap in the magnetic clutch corresponds to the nominal value.

Nominal value - 0.3 - 0.5 mm

Note: if the measured gap does not correspond to the nominal value, then make the necessary adjustment of the gap by changing the number of shims.

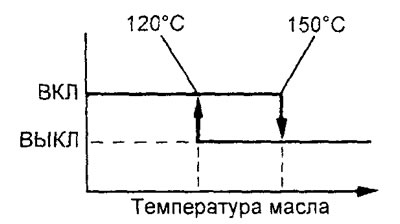

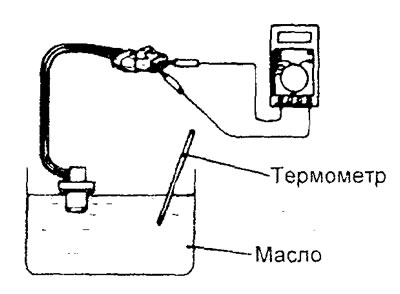

Double switch test for refrigerant temperature

1. Immerse the measuring part of the switch in oil. Then heat the oil with a gas burner or similar.

b) When the oil temperature reaches the specified value, check that the circuit is open between the sensor-switch terminals.

Rated value:

- OFF-ON - 150°C

- ON-OFF - 120°C