Checking the speedometer

Note: A possible cause of speedometer malfunction is a malfunction of the vehicle speed sensor, an open in the wiring harness, or a malfunction in the speedometer itself.

1. Adjust tire pressure to nominal value.

Attention: avoid fitting mixed types and sizes of tires/rims, as this will adversely affect driving safety and the accuracy of the speedometer/odometer readings.

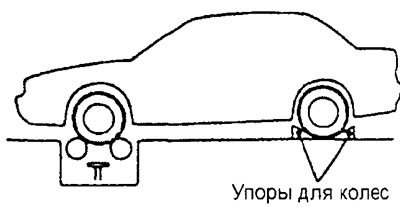

2. Put the car on the running drums and put the stops under the rear wheels.

2WD Models

Check that the parking brake is applied.

2WD Models

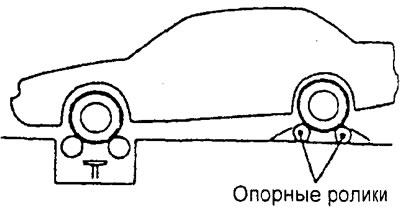

4WD Models

Fasten the rear castors securely to the floor so that their position matches the wheelbase and tire treads as shown in the illustration.

4WD Models

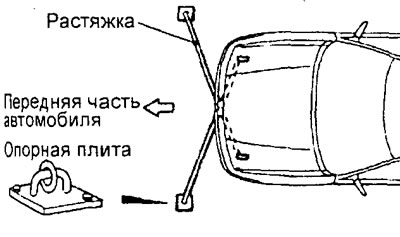

3. To prevent the front wheels from moving from side to side, put two braces on the vehicle's towing hooks, the ends of which are securely fastened to the base plates.

4. To prevent the vehicle from moving forward, attach one end of the cable to the rear tow hook and securely attach the other end of the cable to the base plate.

5. Check up that indications of a speedometer lie in a range of nominal values.

Table. Nominal values of the speedometer readings.

| Speed, km/h | Permissible range of values, km/h |

| 40 | 37-45 |

| 80 | 75-88 |

| 120 | 113-132 |

| 160 | 150-176 |

Attention: do not allow a sharp increase / decrease in speed during the test.

Checking the tachometer

Note: A possible cause of a tachometer malfunction is damage to the power circuit, flesh contact with "weight", lack of an input signal from the engine control unit or a malfunction in the tachometer itself.

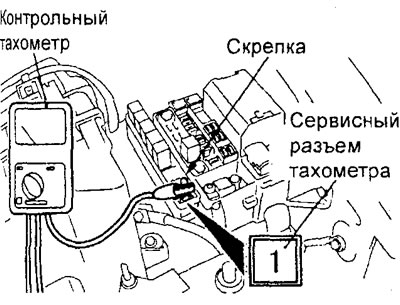

1. To check the tachometer without a tester, install a paper clip into the service connector of the tachometer from the wiring side and connect the control tachometer.

Note: to check the car's stock tachometer, it is recommended to use a tachometer with an inductive type sensor that is connected to a high voltage spark plug wire.

2. With the engine running, compare the readings of the standard tachometer with the readings of the tester or control tachometer at each set engine speed. If the error of the standard tachometer exceeds the allowable value, then replace the tachometer.

Attention:

- - Incorrect connection of the tachometer (power polarity reversal) will damage it.

- - Be careful when replacing the tachometer, do not drop it or let it hit other parts.

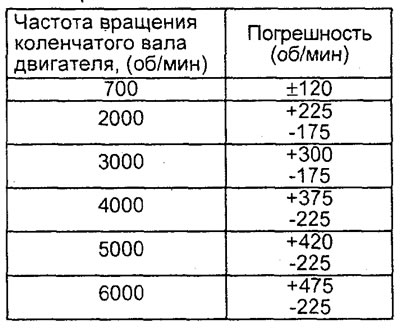

Table. Rated values.

Checking the fuel gauge

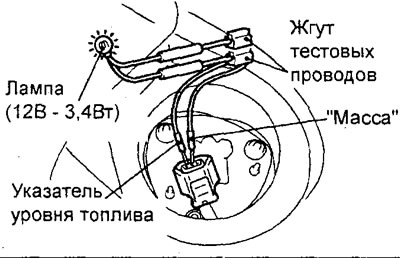

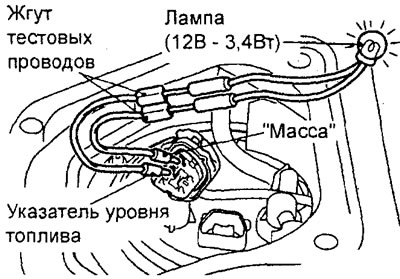

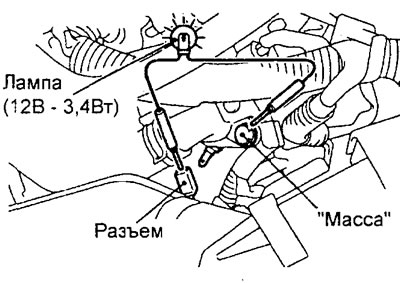

1. Disconnect the fuel level sensor connector (2WD models) or main fuel level sensor (4WD models) based on the fuel pump.

2. Connect the lamp (12V - 3.4W) between pins "1" And "2" connector on the wiring harness side.

2WD models.

4WD models.

3. Turn the ignition key to position "ON".

4. Check the condition of the lamp. If the lamp does not light up, then check the connectors and wiring, repair if necessary.

5. If the lamp lights up, then check the condition of the arrow of the fuel gauge. If the arrow remains motionless, then replace the pointer.

6. If the lamp lights up and the arrow of the fuel level indicator in the tank moves to the middle position, then the fuel level sensor in the tank is faulty.

Checking the fuel level sensor

Note: To check, remove the fuel level sensor from the fuel tank (see chapter "fuel injection system").

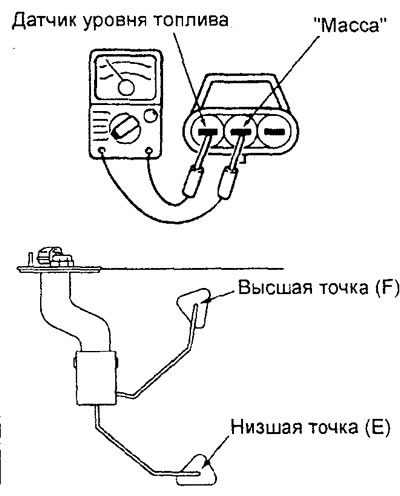

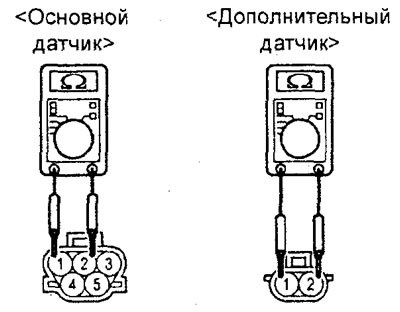

1. Checking the resistance of the fuel level sensor.

A) Check that the resistance between the output of the fuel level sensor and the output "masses" corresponds to the nominal value when the float of the sensor is at its highest point "F" and lowest point "E".

2WD models.

4WD models.

Rated values:

2WD Models:

- Highest point "F" — 3±1 Ohm

- lowest point "E" — 110±1 Ohm

4WD Models:

Main sensor:

- Highest point "F" — 2±1 Ohm

- lowest point "E" — 40.6±1 Ohm

Additional sensor:

- Highest point "F" — 2±1 ohm

- lowest point "E" — 69.4±1 Ohm

b) Check that the resistance value changes smoothly as the float moves slowly between the highest point "F" and lowest point "E".

V) If the test results are not as specified, replace the sensor.

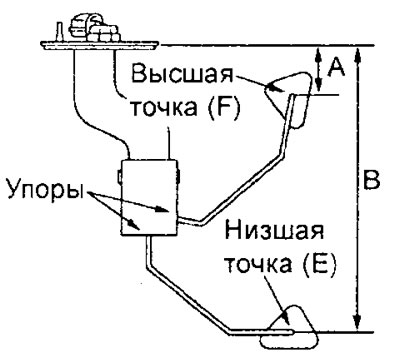

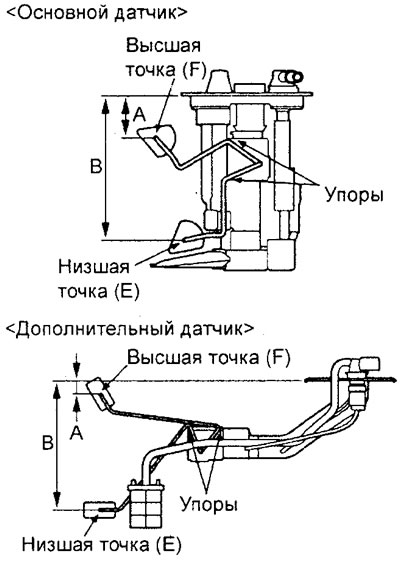

2. Checking the float of the fuel level sensor.

By moving the float until it touches the stops, measure the height "A" at the highest point "F" and height "IN" at the lowest point "E".

2WD models.

4WD models.

Table. Rated values.

| Sensor | A (mm) | IN (mm) |

| 2WD | 24,4 ± 1 | 151,6±2 |

| Sensor | A (mm) | IN (mm) |

| 4WD-basic | 40,5 ±4 | 136 + 4 |

| 4WD optional | 15,8 | 154 |

Checking the engine coolant temperature gauge

1. Disconnect the engine coolant temperature sensor connector (pointer).

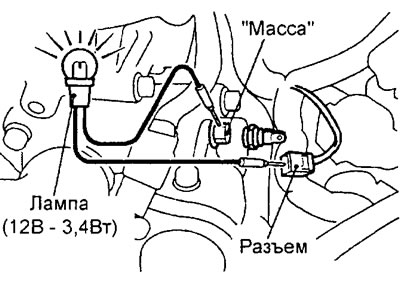

2. Connect the lamp (12V - 3.4W) between the harness-side connector and "weight".

Models with 4G15 engine.

Models with 4G93 engine.

3. Turn the ignition key to position "ON".

4. Check the condition of the lamp. If the lamp does not light up, then check the connectors and wiring, if necessary, repair.

5. If the lamp has lit up, then check up a condition of an arrow of the index of temperature of a cooling liquid. If the arrow remains motionless, then replace the pointer.

6. If the lamp lights up and the arrow of the coolant temperature gauge moves to the middle position, then the coolant temperature gauge sensor is faulty.

Checking the engine coolant temperature gauge sensor

Note: to remove and install the coolant temperature gauge sensor, see the chapter "Cooling system".

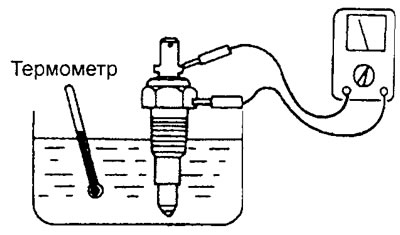

1. Place the measuring part of the sensor in hot water at a temperature of 70°C and measure the resistance between the sensor leads.

Rated value (at 70°С) — 104±13.5 Ohm

Reference values:

| Temperature (°C) | Resistance (Ohm) |

| 50 | 230 |

| 60 | 155 |

| 80 | 73 |

2. If the resistance is not as specified, replace the sensor.

Note: Before installing, apply sealant to the threads of the engine coolant temperature gauge sensor.