Note: Lamp replacement is described in chapter "Manual".

Headlight adjustment

Preparing to adjust the headlights

1. Check the headlight assemblies for faults, corrosion, element defects. Correct any faults before making adjustments.

2. Bring the pressure in the tires to the nominal value.

3. (If a headlight range control switch is installed) Set the headlight range control switch to position "0".

4. Leave the engine running at 2000 rpm to fully charge the battery.

5. If the fuel tank is not full, place a load in the luggage compartment at the rate of 0.8 kg per liter of fuel.

6. Leave only one driver in the car, or put a load of 55 kg in his place.

7. Wipe the headlight lenses thoroughly.

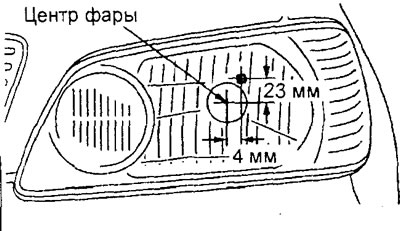

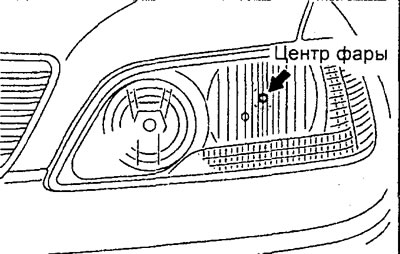

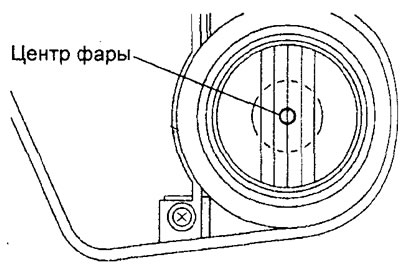

8. Determine the center of the headlight to be adjusted.

Models with single high and low beam lamps.

Models with separate lamps for high and low beams.

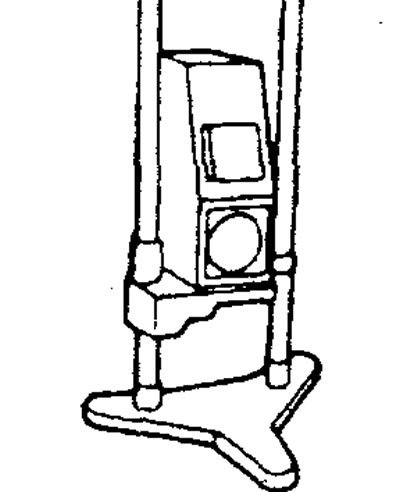

9. Adjustment of the headlight beam should be made using appropriate lighting devices in compliance with the requirements of the manufacturer's instructions for these devices.

Note: If your area has special requirements for vehicle lighting, please adjust the headlights according to these requirements.

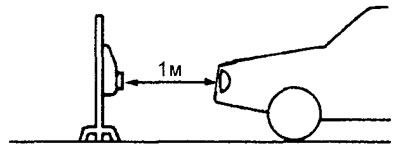

10. Place the car on a flat horizontal platform so that the distance from the center of the headlight to the lighting fixture is 1 m, as shown in the figure.

11. General recommendations for adjustment.

Attention:

- To avoid deformation of the headlamp plastic lens, do not close the headlamp for more than three minutes.

- When adjusting one of the headlights, ensure that the other headlight is disabled by disconnecting the connector.

- When connecting the headlight connector after completing the adjustment, make sure that the headlight setting is not misaligned.

Note: If it is difficult to determine the cut-off of the headlight beam due to outside lighting, use a curtain or additional screen to reduce the influence of outside lighting.

Headlight adjustment (according to European standards)

1. Check the correct position of the headlight beam on the screen.

A) Check for a clear cut-off line and an asymmetric beam image with respect to the vertical line.

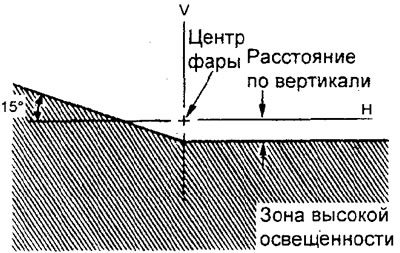

b) In the vertical direction, the beam of headlights must be below the horizontal line "H" by the specified amount.

Nominal value - 7 mm

V) In the horizontal direction, the angle at which the oblique headlight beam line intersects the vertical line "V", must correspond to the nominal value.

Rated value - 15°

2. To adjust the position of the headlight beam, alternately turn the corresponding adjusting screws.

Models with single high and low beam lamps.

Models with separate lamps for high and low beams.

Headlight measurement

1. Place the car on a flat horizontal platform so that the distance from the center of the headlight to the lighting fixture is 1 m.

2. Turn on the dipped beam headlights and, following the instrument manufacturer's instructions, measure the brightness of the headlights with a photometer and check that the measured value corresponds to the nominal value.

Maximum allowable value - not less than 6400 Kandel

Note:

- When measuring the brightness of light, keep the engine speed at least 2000 rpm so that the battery is in a charged state.

- If a light meter is used to measure the brightness of light, then it is necessary to convert its readings into photometer units using the following formula:

I= ER2, Where

- I - brightness of light, Kandel (cd),

- E - illumination, (lux),

- R is the distance in meters from the headlight to the light meter.

Front fog lamp adjustment

Preparing to adjust the front fog lamps

1. Check the front fog lamp assemblies for faults, corrosion, defective elements. Correct any faults before making adjustments.

2. Bring the pressure in the tires to the nominal value.

3. Leave the engine running at 2000 rpm to fully charge the battery.

4. If the fuel tank is not full, place a load in the luggage compartment at the rate of 0.8 kg per liter of fuel.

5. Leave only one driver in the car, or put a load of 55 kg in his place.

6. Thoroughly wipe the fog lamp lenses.

7. Determine the center of the front fog lamp to be adjusted as shown in the illustration.

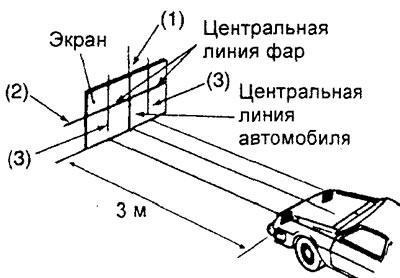

8. Park the vehicle on a level ground so that the distance from the center of the front fog lamp to the screen is 3 m, as shown in the figure.

9. Rock the car in a horizontal direction (left-right) to get a stable position.

10. Rock the vehicle vertically three times while applying force to the hood or front bumper to stabilize the front suspension.

11. Draw four lines on the screen for adjustment.

A) Position the vertical line so that it coincides with the center line of the car (longitudinal axis of the car).

b) measure distance (height) from the center of the front fog lamp to the platform and note the resulting value on the screen. This horizontal line will be used as a reference line for vertical adjustment.

Front fog lamp adjustment

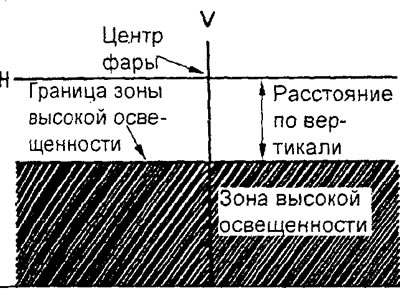

1. Check that the location of the fog lamp beam on the screen is correct.

A) Headlight beam in vertical direction (cut-off line) must be located within the specified range below the horizontal line "H" by the specified amount.

Nominal value - 6 cm (1,15°)

b) In the horizontal direction, the beam of headlights should be parallel to the direction of movement of the car.

Note: Fog lamps cannot be adjusted horizontally. If the headlight beam deviates from the nominal location, check that the headlight is mounted correctly and that there are no defects in the fasteners.

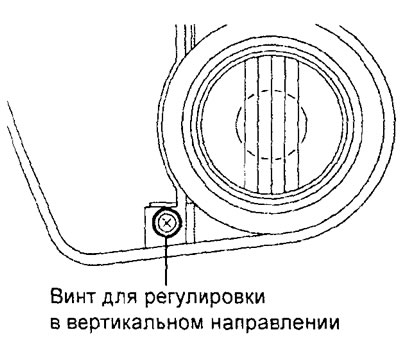

2. To adjust the position of the fog light beam in the vertical direction, turn the adjusting screw.

Attention: when adjusting, be sure to cover other lamps (lighting fixtures), that are not adjusted.

Removal and installation of headlights

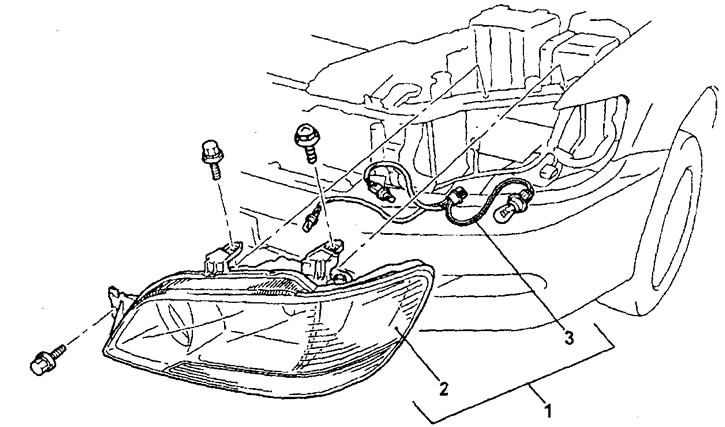

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing headlights".

Removing headlights.1 - headlight assembly, 2 - headlight, 3 - cartridges with wiring assembly.

Installation of details is made in an order, the return to removal.

After completing the installation of the parts, adjust the headlights.

Removal and installation of the light sensor

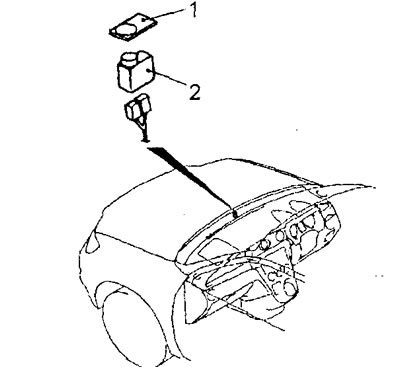

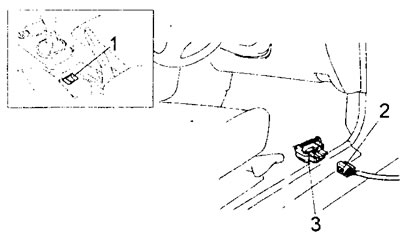

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing the light sensor".

Removing the light sensor.1 - light sensor cover, 2 - light sensor.

When removing parts, pay attention to the operation of removing the light sensor.

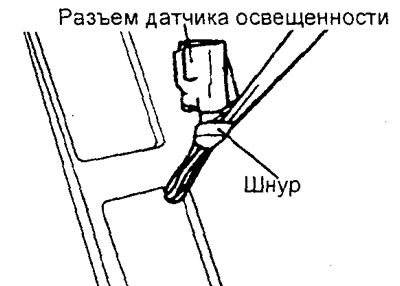

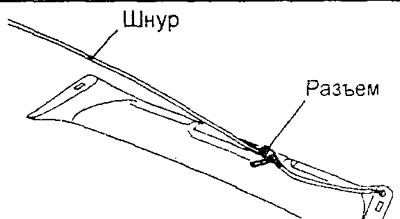

Tie a long enough cord to the light sensor connector, wrap the joint with electrical tape so that it is smooth, and then remove the light sensor from the top side of the instrument panel.

Installation of details is made in an order, the return to removal.

Light sensor test

If the headlights come on when the sensor side of the light sensor is covered by hand and the combination light switch is in the "AUTO", then the light sensor is OK. If the headlights do not turn on, replace the light sensor.

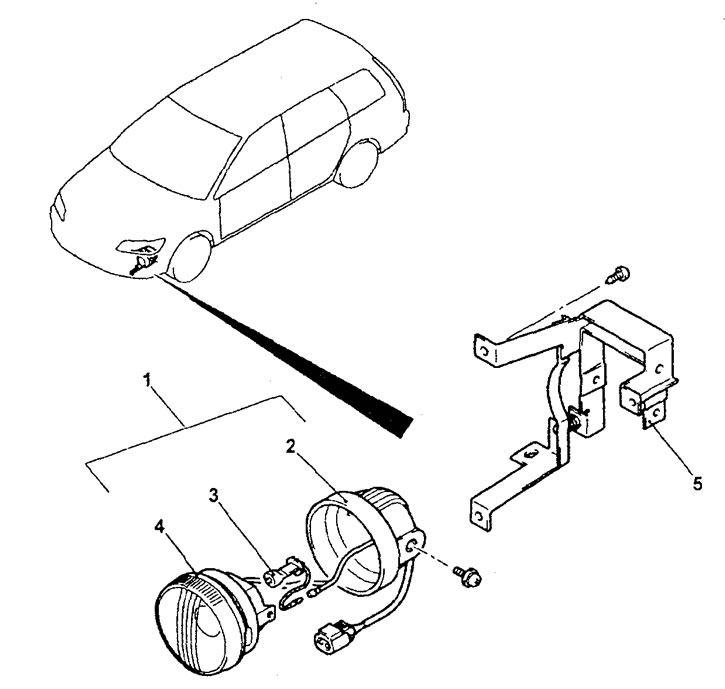

Removal and installation of front fog lights (station wagon)

Before removing the parts, remove the front bumper grille.

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing the front fog lamp".

Removing the front fog lamp. 1 - front fog lamp assembly, 2 - cover, 3 - lamp, 4 - front fog lamp, 5 - front fog lamp mounting bracket.

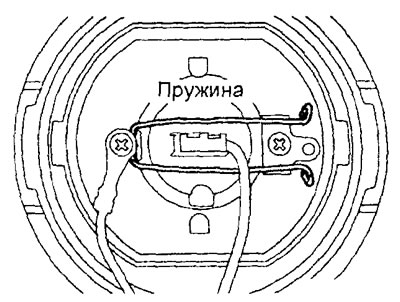

When removing the parts, pay attention to the operation of removing the front fog lamp bulb.

Before removing the front fog lamp bulb, unfasten the bulb retaining spring.

Installation of details is made in an order, the return to removal.

After completing the installation of the parts, install the front bumper grille.

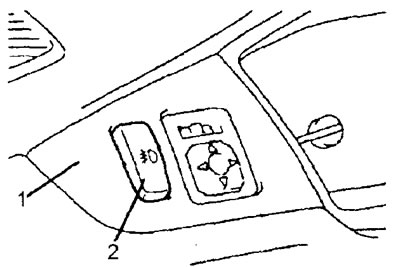

Removal and installation of switches of forward fog lamps

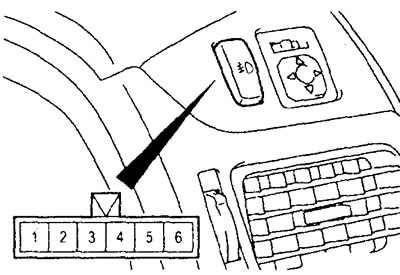

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing the front fog lamp switch".

Removing the front fog lamp switch. 1 - instrument panel overlay on the driver's side, 2 - front fog lamp switch.

Installation of details is made in an order, the return to removal.

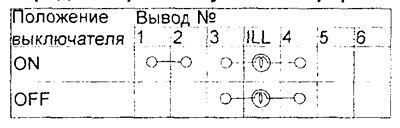

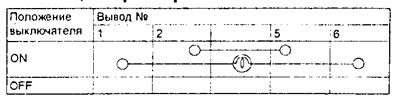

Checking the front fog lamp switch

Check the condition of the circuit between the terminals of the switch connector at various positions of the switch according to the table below.

Table. Checking the front fog lamp switch.

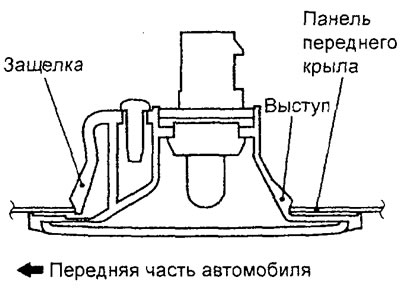

Removal and installation of lateral indexes of turn

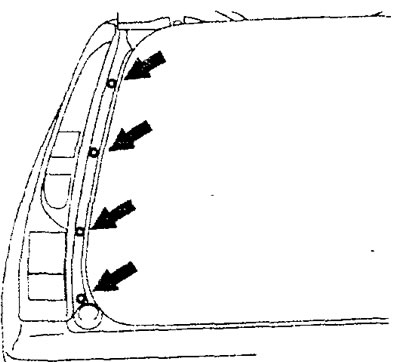

1. Using the special tool, pry up the side turn signal and remove it from the front fender panel.

2. To install the side direction indicator, do the following:

- A) Insert the side turn signal into the front fender panel.

- b) While pressing the side turn signal, secure it with the latch.

Removal and installation of the rear combination lamp

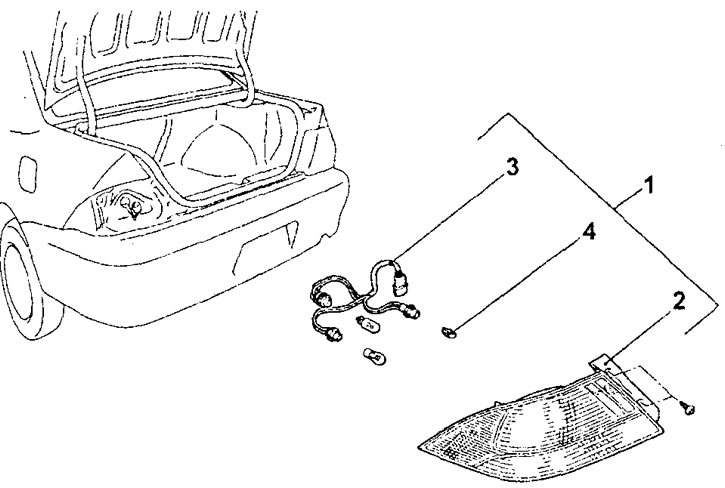

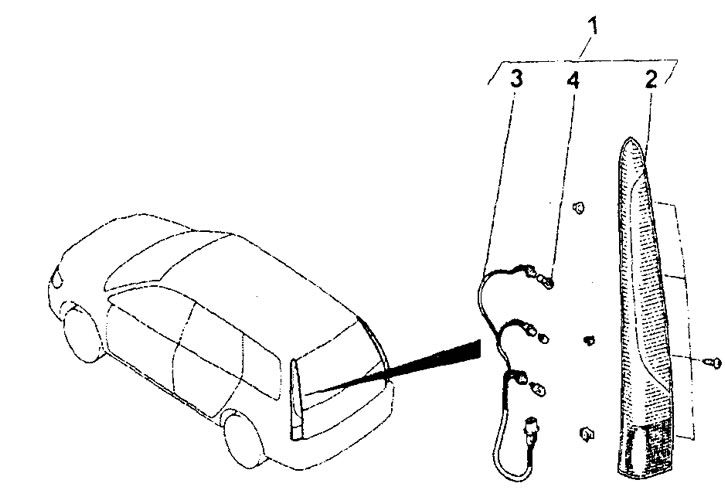

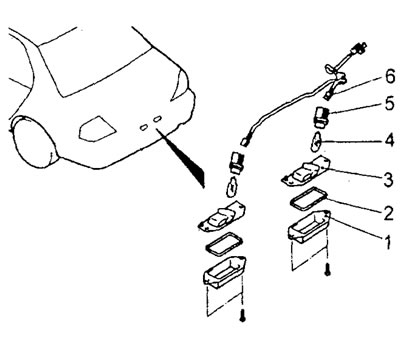

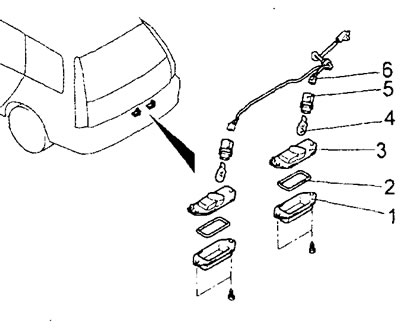

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing the rear combination lamp".

Removing the rear combination lamp (sedan) 1 - rear combination lamp assembly, 2 - rear combination lamp, 3 - cartridges with wiring assembly, 4 - lamp.

Removing the rear combination lamp (station wagon). 1 - rear combination lamp assembly, 2 - rear combination lamp, 3 - cartridges with wiring assembly, 4 - lamp.

− Installation of details is made in an order, the return to removal.

− (station wagon) When installing the parts, pay attention to the installation operation of the rear combination lamp assembly.

When installing the rear combination lamp, securely tighten all mounting screws.

Removal and installation of an additional brake light

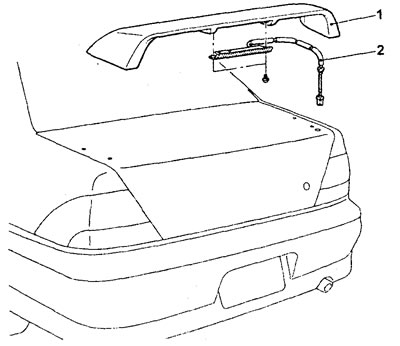

(station wagon) Before you start removing parts, do the following:

- A) Remove the upper rear door trim.

- b) Disconnect the auxiliary brake light connector.

- V) Disconnect the tailgate glass washer hoses.

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing an additional brake light".

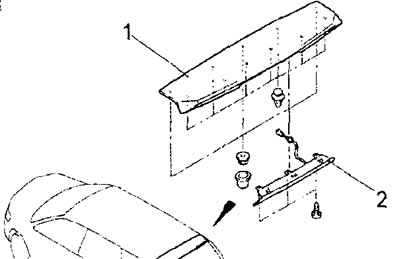

Removing an additional brake light (station wagon). 1 - spoiler (remove the windshield washer jet), 2 - additional top signal.

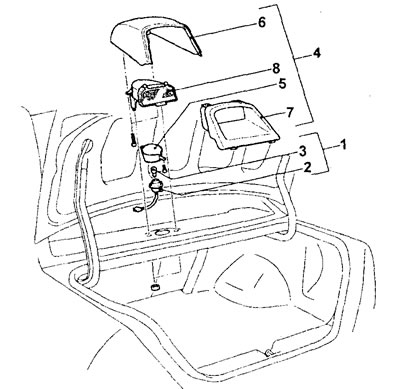

Removing an additional brake light behind the rear window (sedan).1 - cartridge assembly with a lamp, 2 - cartridge, 3 - lamp, 4 - additional brake light assembly, 5 cartridge holder, 6 - upper cover of the additional brake light, 7 - lower cover of the additional brake light, 8 - additional stop signal.

Removing an additional brake light on the spoiler (sedan). 1 - spoiler, 2 - additional brake light.

(Sedan models with an additional brake light on the spoiler) When removing parts, pay attention to the operation of removing the additional brake light.

Tie a sufficient length of cord to the auxiliary brake light connector, wrap the connection with electrical tape so that it is smooth, and then carefully remove the additional brake light.

Installation of details is made in an order, the return to removal.

After completing the installation of the parts, perform the following operations:

- A) Establish the top section of a back door.

- b) Connect the tailgate glass washer hoses.

- V) Connect a socket of an additional stoplight.

Removing and installing license plate lights

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing foot sign lamps".

Removing license plate lights (sedan). 1 - license plate lamp diffuser, 2 - seal, 3 - license plate lamp housing, 4 - license plate lamp, 5 - lamp socket, 6 - wiring harness.

Removing license plate lights (station wagon). 1 - license plate lamp diffuser, 2 - seal, 3 - license plate lamp housing, 4 - license plate lamp, 5 - lamp socket, 6 - wiring harness.

Installation of details is made in an order, the return to removal.

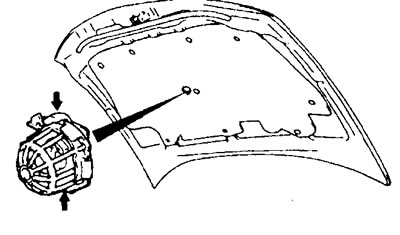

Removal and installation of a lantern of illumination of a motor compartment

1. Press the latches on the engine compartment light as shown in the illustration and remove the light.

2. Installation of details is made in an order, the return to removal.

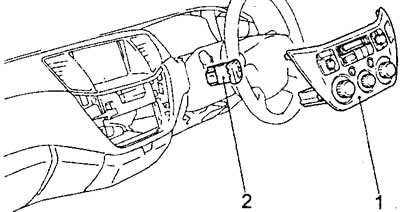

Removal and installation of the floor lamp

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing the floor lamp".

Installation of details is made in an order, the return to removal.

Removing the floor lamp. 1 - floor lamp switch (remove the lower instrument panel trim from the driver's side), 2 - floor lamp connector, 3 - floor lamp.

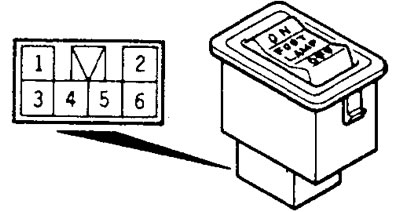

Checking the floor lamp switch

Check the condition of the circuit between the terminals of the switch connector at various positions of the switch according to the table below.

Table. Checking the switch.

Removal and installation of the alarm switch

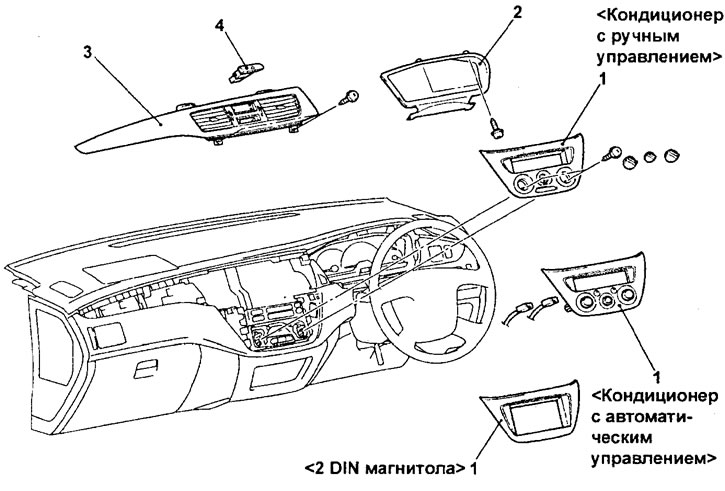

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing the Hazard Switch".

Removing the Hazard Switch (models with MMCS system). 1 - heater and air conditioner control panel assembly, 2 - alarm switch.

Removing the Hazard Switch (models without MMCS). 1 - heater and air conditioning control panel assembly or radio overlay, 2 - trim of the instrument cluster, 3 - central trim of the instrument panel, 4 - alarm switch.

Installation of details is made in an order, the return to removal.

Hazard switch test

Check the condition of the circuit between the terminals of the switch connector at various positions of the switch according to the table below.

Table. Circuit breaker test

.