Removing

− Drain the power steering hydraulic fluid before removing parts.

− Removal of parts is carried out in the order of numbers indicated in the figure "power steering pump".

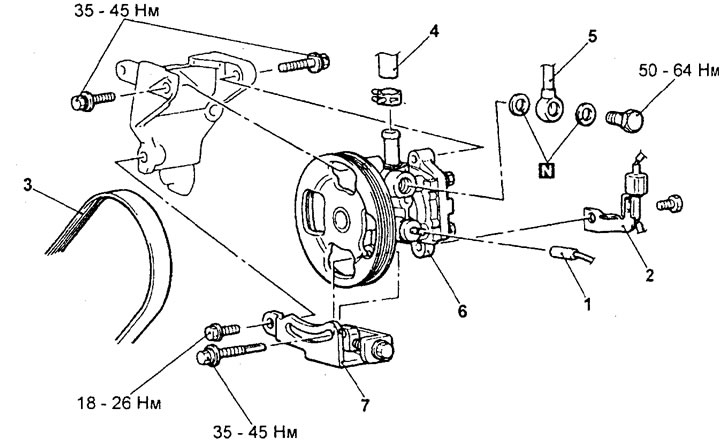

power steering pump (models with 4G15 engines). 1 - sensor connector for the fluid pressure switch in the hydraulic system of the booster, 2 - crown matte of the air conditioning compressor wiring harness, 3 - drive belt 4 - inlet hose, 5 - pressure hose, 6 - power steering pump 7 - power steering pump bracket.

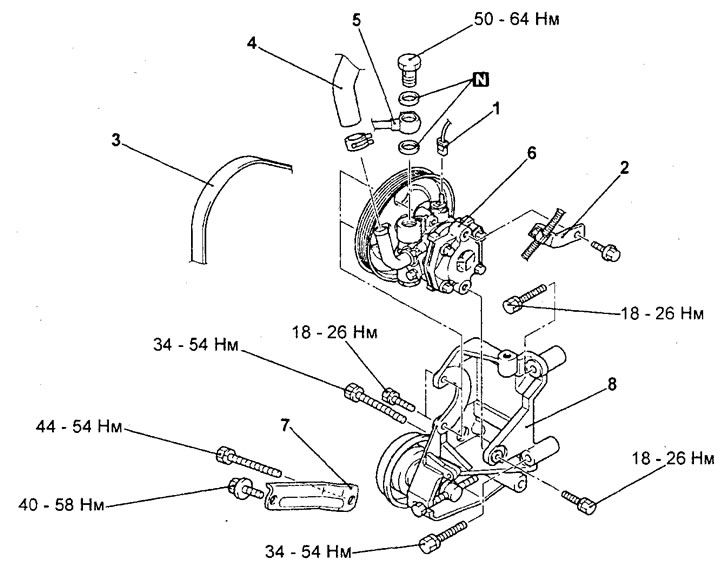

power steering pump (models with 4G93 engines). 1 - connector of the sensor-switch for fluid pressure in the hydraulic system of the amplifier, 2 - bracket for the wiring harness of the air conditioning compressor, 3 - drive belt, 4 - inlet hose, 5 - pressure hose, 6 - power steering pump, 7 - bracket plate, 8 - pump bracket hydraulic booster.

− When removing the parts, pay attention to the procedure for removing the power steering pump assembly.

Remove the A/C compressor mounting bolt and disconnect the A/C compressor, then remove the pump assembly.

Attention: when performing this operation, do not disconnect the pipelines of the air conditioning system from the air conditioning compressor.

Check before installation

1. Check the drive belt for cracks.

2. Check for imbalance when rotating the pulley assembly.

Disassembly

− Removal of parts is carried out in the order of numbers indicated in the figure "Power steering pump disassembly".

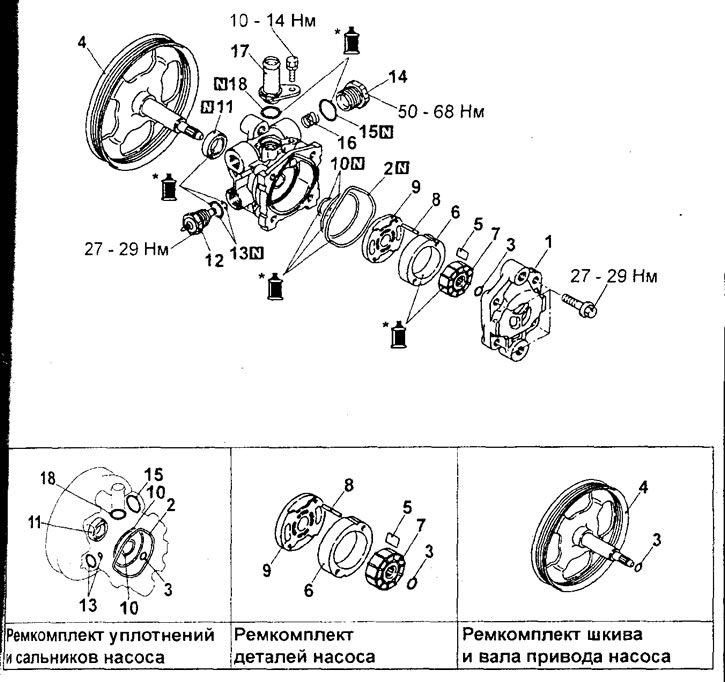

Power steering pump disassembly (models with 4G 15 engines). 1 - pump cover, 2 - O-ring, 3 - circlip, 4 - pump drive pulley and shaft, 5 - vane, 6 - cam washer, 7 - rotor, 8 - lock pin, 9 - side plate, 10 - O-rings, 11 - stuffing box, 12 - fluid pressure switch in the booster hydraulic system, 13 - O-rings, 14 - plug, 15 - O-ring, 16 - flow control spring, 17 - inlet hose connecting pipe, 18 - O-ring.

Attention: it is forbidden to disassemble the pressure switch and valve assembly, as they are not separable.

Note: Apply Mitsubishi ATF-SPII to the marked areas.

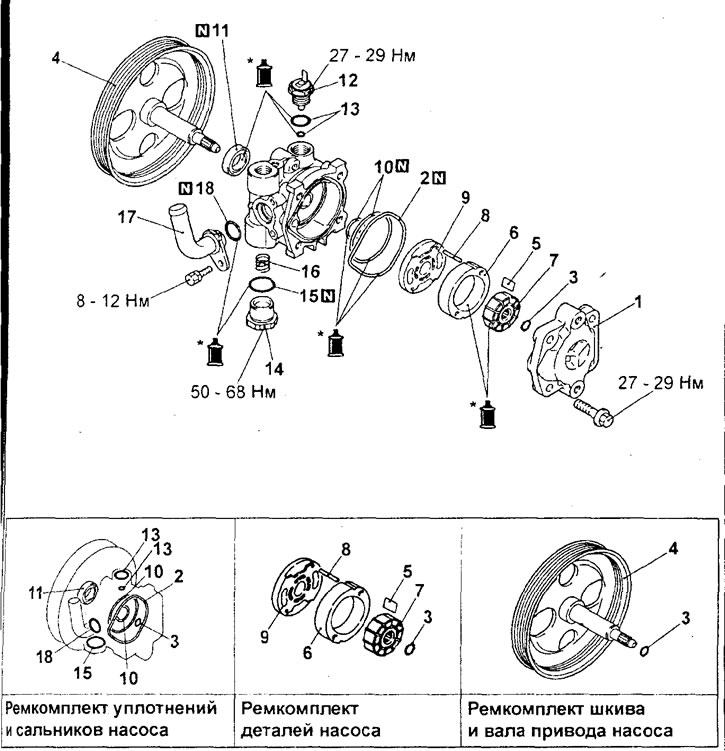

Power steering pump disassembly (models with 4G93 engines). 1 - pump cover, 2 - O-ring, 3 - circlip, 4 - pump drive pulley and shaft, 5 - vane, 6 - cam washer, 7 - rotor, 8 - lock pin, 9 - side plate, 10 - O-rings, 11 - stuffing box, 12 - fluid pressure switch in the booster hydraulic system, 13 - O-rings, 14 - plug, 15 - O-ring, 16 - flow control spring, 17 - inlet hose connecting pipe, 18 - O-ring.

Attention: it is forbidden to disassemble the pressure switch and valve assembly, as they are not separable.

Note: in places marked "*", apply Mitsubishi A TF-SPII.

Check before assembly

1. Check for fluid flow control valve blockage.

2. Check the pulley assembly for wear or damage.

3. Check absence "stepped" wear of the blades and grooves of the rotor.

4. Check absence "stepped" wear on the contact surface of the blades and the cam.

5. Check the blades for damage.

Pump Assembly

− Pay attention to the following operations when installing parts.

1. Installation of ring gaskets.

Before installation, apply the recommended liquid to all O-rings, the dimensions of the O-rings are selected according to the table below.

| Gasket No. in the figure | Inner diameter x width, mm |

| 1 | 15.8 x 2.4 |

| 2 | 21.0 x 1.9 |

| 3 | 14.8 x 2.4 |

| 4 | 3.8 x 1.9 |

| 5 | 14.8 x 1.9 |

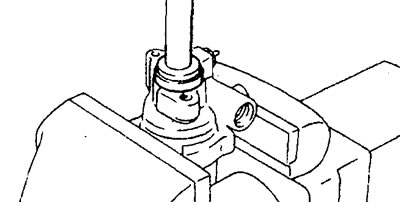

2. Installation of the gland.

Using the special tool, install the oil seal as shown in the illustration.

3. Installing the pump side plate. Install the side plate, positioning it as shown in the figure.

6. Installing the blades.

Install the blades into the rotor, paying special attention to the correct installation direction.

Installation

− Installation of parts is carried out in the reverse order of removal.

− After installing the parts, perform the following operations.

A) Pour working fluid into the power steering hydraulic system.

b) Adjust the tension of the power steering pump drive belt.

V) Bleed air from power steering hydraulic system.