Preparatory operations

1. When checking the alignment of the front wheels with the special tool, always place the vehicle on a level and level surface so that the front wheels are in a straight-ahead position.

2. Before checking, make sure that the front suspension, steering and wheels are in good technical condition. Also, check that the vehicle is on a level surface, the wheels are in a straight-ahead position, and the tire pressure is correct.

Caution: Worn or damaged front and rear suspension parts must be replaced prior to checking and adjusting wheel alignment.

Beat

1. Hang the wheels of one of the axles of the car and install safety racks under the car.

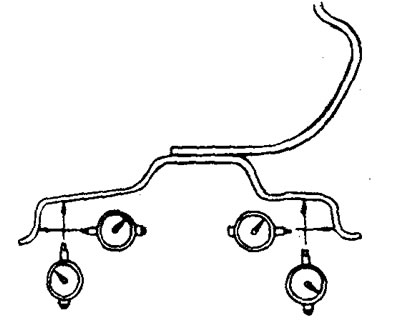

2. Measure wheel runout with a dial gauge as shown in the illustration.

3. Replace the wheel if its runout exceeds the limit.

Maximum allowable runout:

- radial - 1.0 mm

- axial - 1.2 mm

- Tightening torque - 90 -110 Nm

Convergence

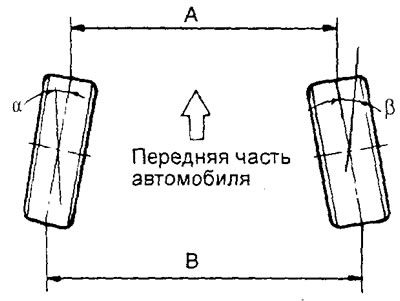

1. Wheel alignment (size difference B - A or the sum of the angles α + β) adjustable by turning the tie rod ends.

2. Measure the toe of the front wheels. Nominal convergence 1±2 mm

3. If the convergence of the front wheels does not correspond to the nominal value, then perform the adjustment.

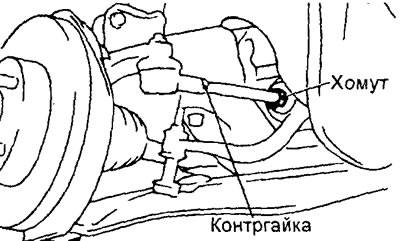

A) Loosen the tie rod end nuts.

b) To change the wheel alignment, rotate the ends of the right and left steering rods at the same angles in opposite directions.

V) Tighten the tie rod end nuts.

Steering angles

1. Mount the front wheels on a turn radius measuring stand and measure the steering angles.

Rated value:

- Inner wheel - 40°40'±1°30'

Outer wheel (for reference):

- sedan models - 33°

- station wagon models - 33°20'

2. If the steering angles do not correspond to the nominal values, then the amount of convergence of the front wheels is probably not adjusted. Adjust the toe and check the steering angles again.

Camber, pitch and roll

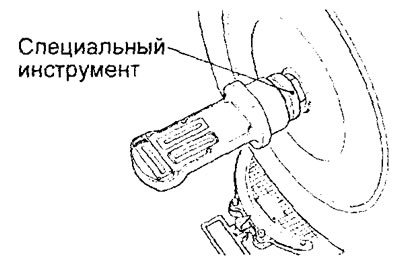

1. Measure the camber, caster and lateral tilt of the front axle with a special tool.

Rated value:

Sedan models:

Models since 05.2000:

- Camber — 0°00'±30'

- Pitch - 2°50'±30'

Models since 07.2000:

- Camber — 0°05'±30'

- Pitch - 2°45'±30'

Station wagon models:

2WD models, except for low body models:

- Camber — 0°00'±30'

- Pitch - 2°35'±30'

Low body models:

- Camber — -0°05'±30'

- Pitch - 2°45'±30'

4WD Models:

- Camber - 0°05'±30'

- Pitch - 2°35'±30'

Note: The difference between the measured values for the left and right wheels should be no more than 0°30'.

Attention:

- For vehicles with cast aluminum wheel rims, install the sensor for checking the angles of the steering wheels on the wheel drive shaft using a special adapter. Tighten the special adapter with the same tightening torque as the drive shaft mounting nut.

Tightening torque - 226 +49 N.m

- It is forbidden to load the bearings of the front wheel hubs with the weight of the car with loose nuts securing the wheel drive shafts.

2. If the camber of the front wheels is out of specification, check the front suspension units and replace any deformed or damaged parts.

Side sliding

Measure side slip on a special slip tester.

Nominal value - 0±3 mm

Checking the protective covers of ball joints

1. Put your finger on the protective cover and check the cover for wear, damage, cracks, abrasions and deterioration.

2. If mechanical damage to the protective cover is found, then replace the front suspension lower arm assembly or the front suspension stabilizer bar.

Attention: Cracks and damage to the protective boot can lead to damage to the ball joint.

Note: If the protective cover has been damaged during maintenance work, the protective cover must be replaced with a new one and the test must be repeated.