Removal and installation

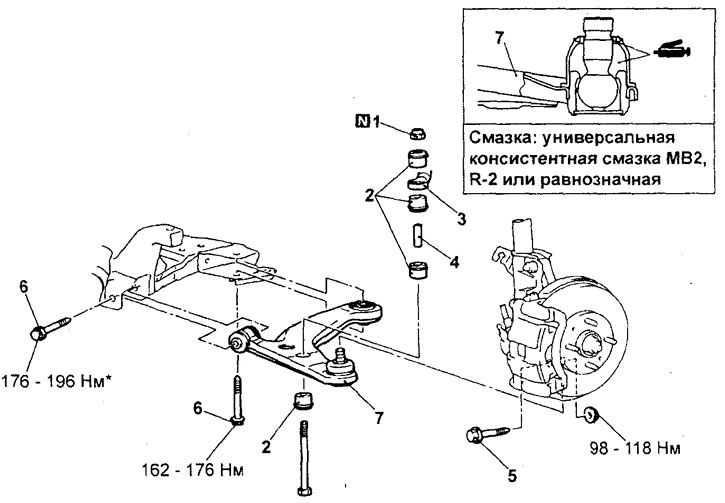

− Removal of parts is carried out in the order of numbers indicated in the figure "Removing the lower front suspension arm".

− When removing the parts, pay attention to the operation to detach the lower arm from the subframe.

Removing the lower front suspension arm. 1 - locknut, 2 - stabilizer rubber bushing, 3 - anti-roll bar, 5 - connection of the lower arm and steering knuckle, 6 - connection of the lower arm and cross beam assembly, 7 - lower arm assembly.

Attention: it is only necessary to pre-tighten the bolt marked with the sign and make the final tightening on an unloaded vehicle after lowering it onto the wheels.

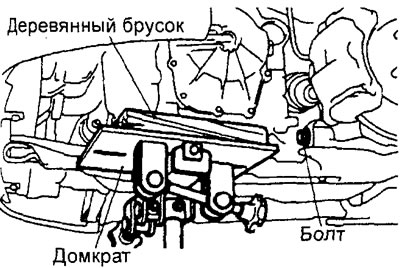

To facilitate the release of the lower control arm from the subframe, jack up the transmission using a transmission jack.

− Installation of parts is carried out in the reverse order of removal.

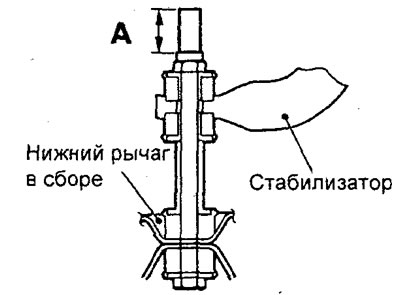

− When installing the parts, pay attention to the operation of installing the locknut.

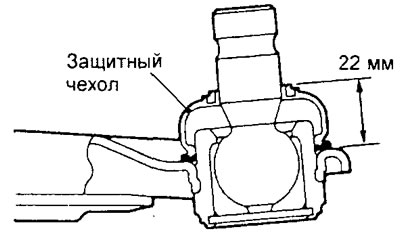

Tighten the locknut so that the length "A" the protruding part of the stabilizer mounting bolt corresponded to the nominal value.

Nominal value - 20.5 - 23.5 mm

− After installing the parts, perform the following operations.

A) Check the protective cover for cracks or damage.

b) Check and adjust the angles of the front wheels.

Examination

1. Check bushing for wear and damage.

2. Check the lower arm for bending or damage.

3. Check the condition of all bolts.

4. Check the condition of the protective boot of the ball joint of the lower arm (see the relevant subsection under "Additional checks").

Attention:

- - Cracks and damage to the protective boot can cause damage to the ball joint.

- - If the protective cover is damaged during maintenance work, replace the protective cover with a new one and repeat the check.

Check of the moment of the beginning of rotation of a finger of a spherical support of the lower lever

1. Shake the ball joint pin several times, screw the nut onto it, and, using a special torque wrench, measure the moment when the ball joint pin begins to rotate.

Rated value - 0 - 3.9 Nm

2. If the measured value exceeds the nominal value, or the rotation of the ball joint is difficult or not smooth (jamming), replace the lower arm assembly.

Replacement of a protective cover of a spherical support of the lower arm

Attention: the protective cover is only replaced if it is damaged during maintenance work.

1. Remove the protective cover.

2. Apply multipurpose grease to the lip of the boot and place the grease inside the new boot.

Lubrication - universal grease MB2, R-2 or equivalent

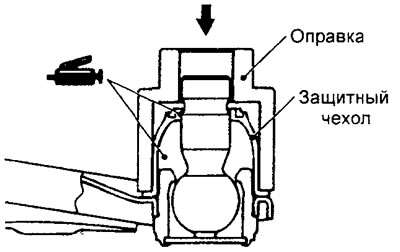

3. Using the special tool, install the protective boot on the ball joint until it is fully seated.

4. Make sure the protective cover is positioned as shown. Check for unusual protrusions or stretching of the protective boot.

5. Check the protective cover for cracks or damage.

Lower arm rear bushing replacement

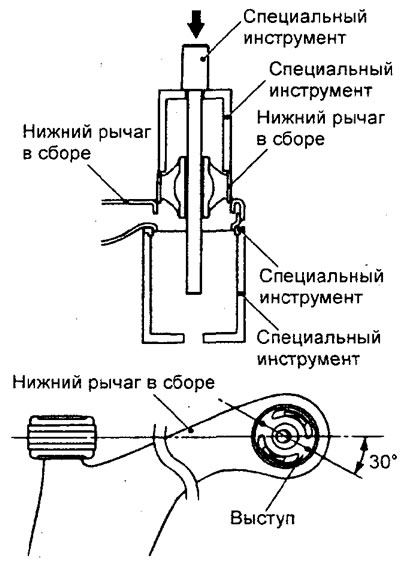

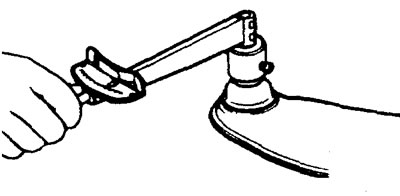

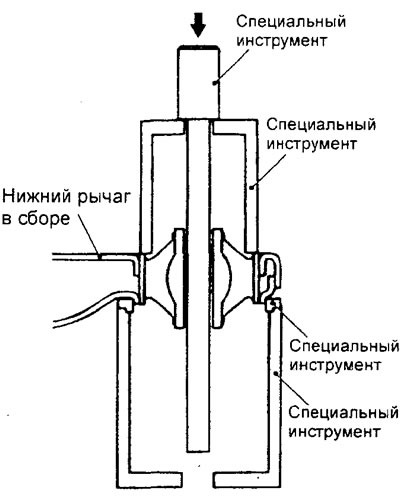

1. Using the special tool, remove the bushing from the lower arm.

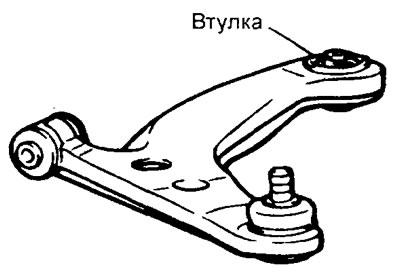

2. When pressing in, install the sleeve so that its protrusion is located as shown in the figure.

3. Using the special tool, press in the lower arm bushing so that the outer edge of the bushing is flush with the surface of the lower arm assembly.