Removal and installation

− Perform the following operations before starting to remove parts.

A) Loosen the parking brake cable adjusting nut.

b) Drain the brake fluid.

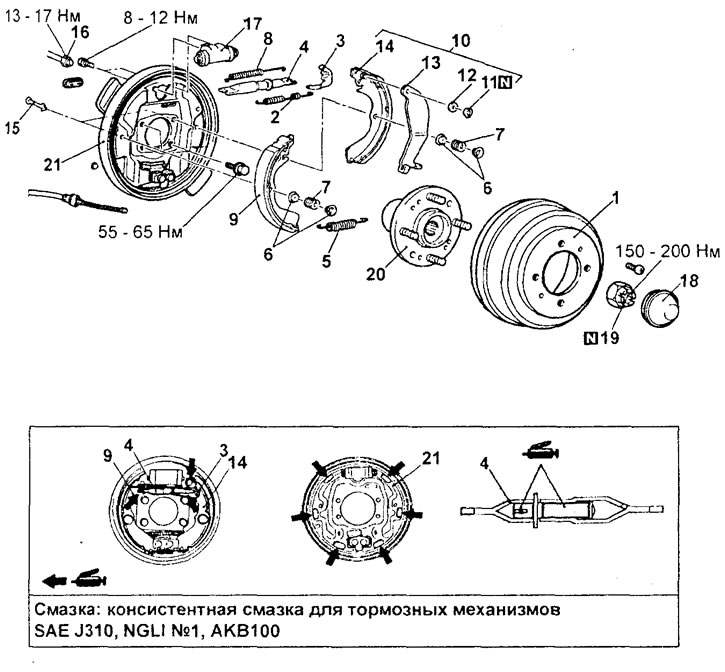

− Removal of parts is carried out in the order of numbers indicated in the figure "Rear drum brakes".

Rear drum brakes. 1 - brake drum, 2 - auto adjuster spring, 3 - auto adjuster lever, 4 - auto lash adjuster assembly, 5 - bottom shoe return spring, 6 - shoe support pin caps, 7 - shoe support pin spring, 8 - top return shoe spring, 9 - brake shoe with lining assembly, 10 - brake shoe with lining and parking brake lever assembly, 11 - retainer, 12 - convex washer, 13 - parking brake lever, 14 - brake shoe with lining assembly, 15 - pad support pin, 16 - brake pipe connection, 17 - working brake cylinder, 18 - hub cap, 19 - lock nut, 20 - hub, 21 - brake support shield.

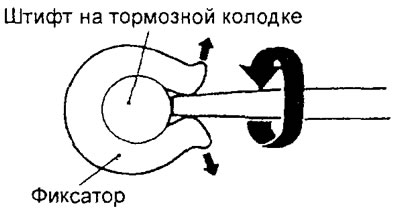

− When removing parts, pay attention to the operation of removing the latch.

Using a slotted screwdriver, spread the antennae of the latch and remove it.

− Installation of parts is carried out in the reverse order of removal.

− When installing parts, pay attention to the following operations:

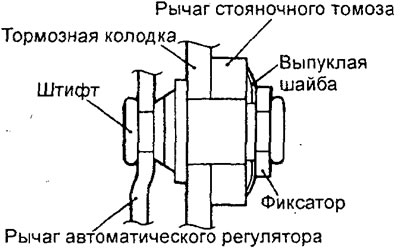

1. Installing the convex washer.

Install the convex washer as shown in the illustration.

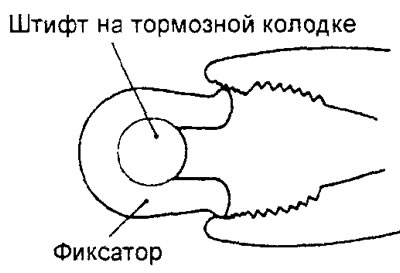

2. Installing the latch.

Using pliers, install and tighten the retainer on the pin.

− After completing the installation of the parts, perform the following operations:

- A) Adjust the travel of the parking brake lever.

- b) Refill with brake fluid.

- V) Remove air from the brake hydraulic drive.

Dismantling and assembly of the working brake cylinder

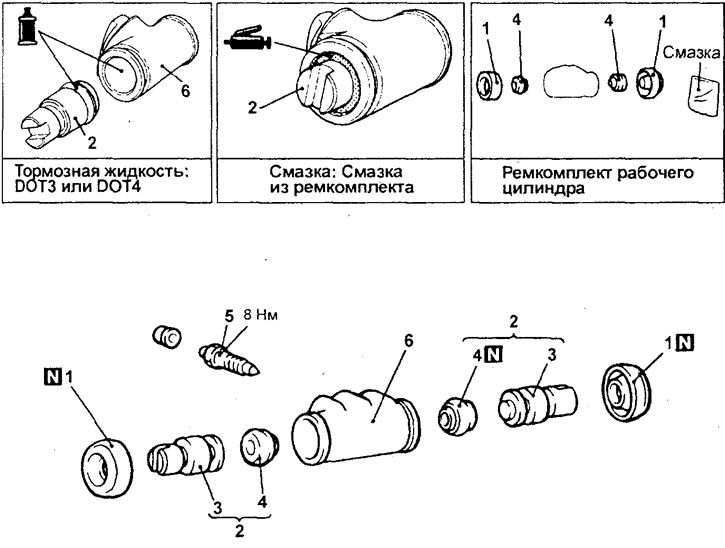

− Removal of parts is carried out in the order of numbers indicated in the figure "Disassembly of the working brake cylinder".

Disassembly of the working brake cylinder of the rear drum brakes. 1 - boot, 2 - piston assembly, 3 - piston, 4 - piston sealing ring, 5 - air bleed screw, 6 - brake cylinder housing.

Attention: use only special grease from the repair kit in the brakes.

− Installation of parts is carried out in the reverse order of removal.

− When installing the parts, pay attention to the installation procedure of the piston and its O-ring.

A) Before assembly, flush the piston and brake cylinder with alcohol or brake fluid.

b) Lubricate the piston o-ring and special tool with brake fluid.

Brake fluid type - SAE J1703 or FMVSS 116 DOT3 or DOT4

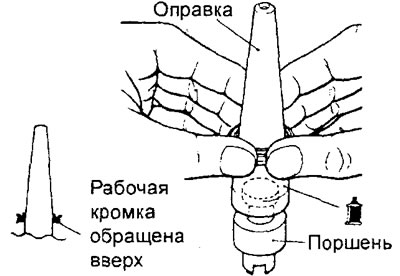

V) Slide the piston sealing ring onto the special mandrel so that the working (acute) the edge was turned up, and then, lowering the mandrel down, install the ring in the piston groove.

Caution: To avoid twisting or misalignment of the piston o-ring during installation, lower it slowly and carefully in one non-stop motion.

Checking the working brake cylinder (after disassembly)

Check for damage or rust on the walls of the working cylinder and piston. At detection of deviations from norm replace the working brake cylinder in gathering.