Checking and replacing brake pads

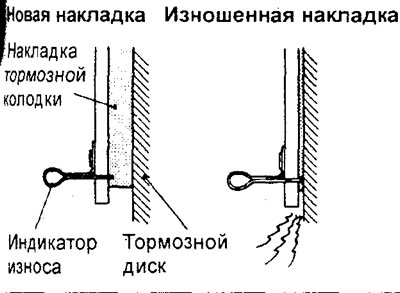

Note: when the thickness of the brake pad lining is reduced to 2, the wear indicator comes into contact with the brake disc and emits a squealing sound while driving to prejudice the driver about the need for a replacement of the brake pads.

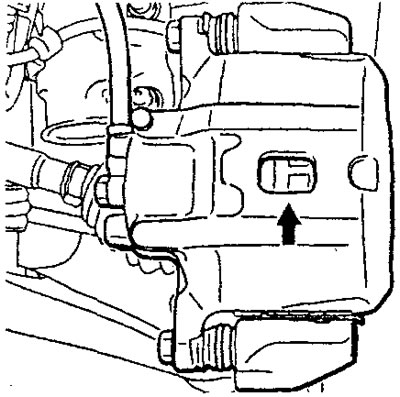

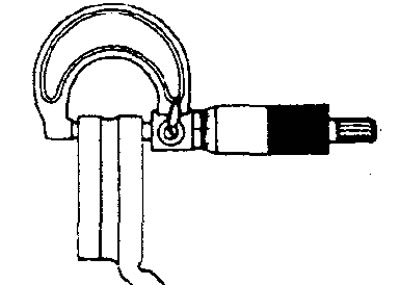

1. Through a special service hole in the brake caliper, measure the thickness of the brake pad lining.

Nominal value - 10 mm

Maximum allowable value - 2 mm

Attention:

- If the lining thickness of any pad is less than the maximum allowable value, then replace the brake pads as a set, in addition, simultaneously replace the brake pads on the opposite wheel of this axle.

- If there is a noticeable difference in the thickness of the brake pads on the left and right sides of the caliper, then check the smoothness of the movement of the caliper along the bushings of the guide and locking fingers.

2. Turn out a bolt a directing finger. Lift the caliper assembly and hang it on the wire.

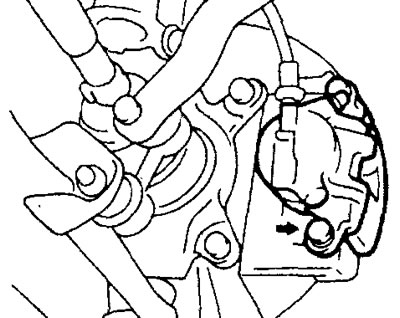

Attention: Do not remove the special grease from the guide and lock pins and do not allow dirt to get on the lock pin.

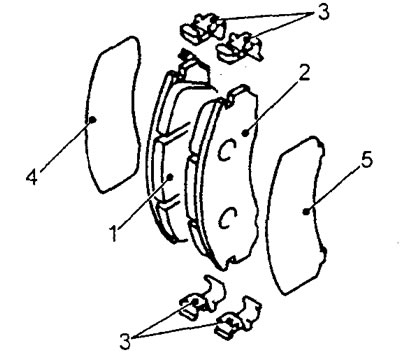

3. Remove the following parts from the caliper bracket.

- brake pad and wear indicator assembly,

- brake pad,

- pad retainers

- inner lining

- outer lining.

Details of the brake mechanism. 1 - brake shoe and wear indicator assembly, 2 - brake shoe, 3 - shoe retainer, 4 - inner gasket, 5 - outer gasket.

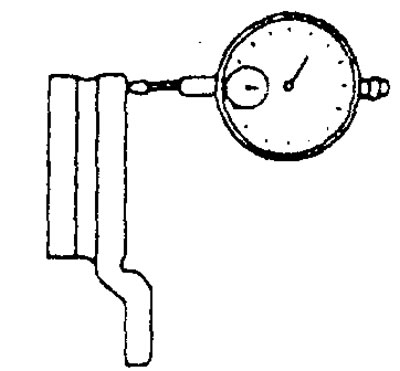

4. With the brake pads removed, use a spring dynamometer to measure the resistance to rotation of the wheel hub in the forward direction.

5. Install the brake pads onto the disc brake caliper bracket and secure with the retainers.

6. Measure the resistance to rotation of the wheel hub when rotating in the forward direction. Determine the amount of resistance to rotation of the wheel hub with disc brakes installed (difference between measured values).

Checking the brake disc

Attention: to ensure the proper operation of disc brakes, special attention must be paid to compliance with the technical requirements for servicing disc brakes.

Note: before recovery operations (before machining) brake disc, check the following parameters.

1. Absence of scratches, rust, wear and impregnation of the disc surface with wear products of the pads.

A) If the vehicle has not been used for some time, the part of the disc surface that has not been in contact with the brake pads will rust, which will lead to increased noise and vibration.

b) If the grooves and scratches that have appeared on the surface of the disc as a result of intensive wear are not removed before installing new brake pads, then normal contact between the disc and the brake pads will not be ensured.

2. No runout or brake disc wear.

Increased runout or wear of the disc will result in increased resistance to the brake pedal due to wheel cylinder piston pulsation.

3. Thickness change (non-parallelism) brake disc.

If the thickness of the brake disc is not uniform around the perimeter, it will cause the brake pedal to vibrate.

4. Warping (flatness) brake disc.

Improper maintenance or overheating will warp the brake disc (flatness).

Checking the thickness of the brake discs

1. Using a micrometer, measure the thickness of the brake disc at eight points approximately every 45°at a distance of 10 mm from the outer edge of the disc.

Nominal value - 24.0 mm

Limit value - 22.4 mm

Note: The difference in brake disc thickness between any two measurement points must not exceed 0.06 mm.

2. If the thickness of the brake disc is less than the maximum allowable value, then remove it and install a new one. If the difference in thickness of the brake disc between different measurement points exceeds the limit, the brake disc must either be replaced or machined on a special lathe.

Checking and correcting the runout of the front brake disc

1. Remove the disc brake caliper assembly, lift and secure the brake out of the way with wire.

2. Inspect the disc surface for deep scratches, rust, and cracks. Thoroughly clean the disc and remove all rust.

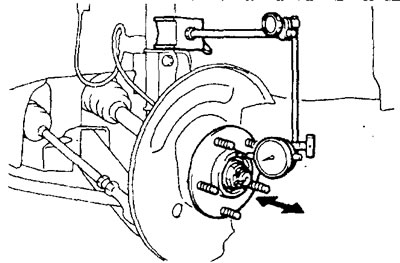

3. Install a dial gauge approximately 5 mm from the outer edge of the brake disc and measure the disc runout.

Maximum allowable value - 0.06 mm

4. If the runout value of the brake disc corresponds to or exceeds the maximum allowable value, then try to change the relative position of the disc and the wheel hub, then measure the runout again.

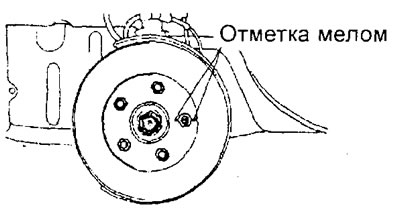

A) Before removing the brake disc at the point of maximum runout, mark both sides of the wheel hub bolt with chalk.

b) Remove the brake disc and install the dial gauge as shown. While moving the hub in the axial direction, measure the axial clearance of the hub bearing.

Maximum allowable value - 0.05 mm

V) If the axial clearance is equal to or greater than the limit, then disassemble the hub and steering knuckle assembly and check the parts (see chapter "Front drive shafts").

G) If the axial clearance in the hub bearing does not exceed the maximum allowable value, then change the position of the brake disc on the hub (turn the brake disc 180°from the chalk mark) install it on the hub and repeat the brake disc runout measurement.

5. If the performed operations did not eliminate the increased runout of the disc, then it is necessary to replace the brake disc or process it on a special lathe.