Removal and installation

Note: The ECM monitors the brake booster vacuum sensor signal and, if it fails, issues the appropriate diagnostic code. Checking the brake booster vacuum sensor, see chapter "fuel injection system".

− Drain the brake fluid before removing parts.

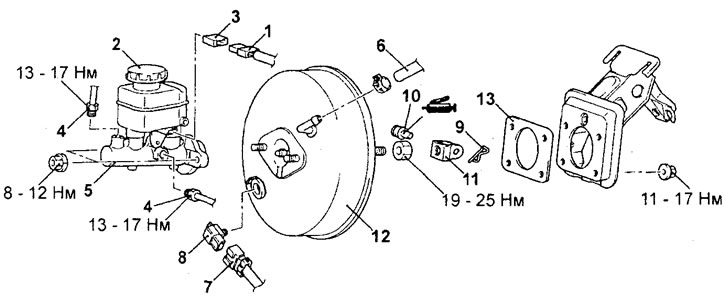

− Removal of parts is carried out in the order of numbers indicated in the figure "Removal of the main brake cylinder and vacuum brake booster".

Removal of the main brake cylinder and vacuum brake booster. 1 - brake fluid level sensor connector, 2 - reservoir, 3 - brake fluid level sensor, 4 - brake pipe, 5 - brake master cylinder, 6 - vacuum hose (with built-in non-return valve), 7 - vacuum booster vacuum sensor connector, 8 - vacuum booster vacuum sensor, 9 - cotter pin, 10 - pin, 11 - plug, 12 - vacuum brake booster, 13 - gasket.

− Installation of parts is carried out in the reverse order of removal.

− When installing parts, pay attention to the following operations:

1. Installation of a vacuum hose.

Push the vacuum hose onto the fitting until it stops against the hexagon of the fitting so that the color mark of the hose is directed forward, then secure the hose with a clamp.

2. Before installing the seal and brake master cylinder, adjust the gap between the brake booster rod and the primary piston.

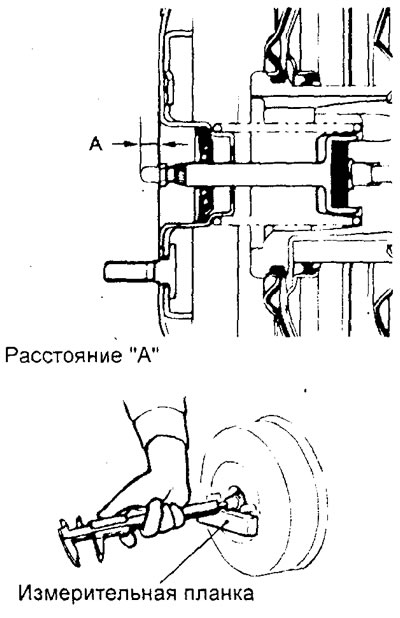

A) Determine the distance "A", as it shown on the picture.

Rated value "A" - 9.18 - 9.43 mm

Note: when creating a vacuum on the vacuum brake booster of 66.7 kPa, the distance "A" will be 10.28 - 10.53 mm.

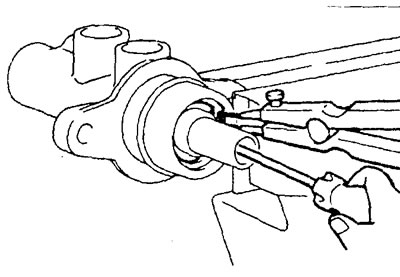

b) If the measured value does not correspond to the nominal value, then adjust it by changing the length of the brake booster rod by turning the rod adjusting screw. Using a ring wrench or tool head, turn the pushrod adjusting screw while holding the stem slot with the special tool as shown in the illustration.

− After completing the installation of the parts, perform the following operations:

- A) Refill with brake fluid.

- b) Remove air from the brake hydraulic drive.

- V) Adjust the brake pedal.

Dismantling and assembly of the main brake cylinder

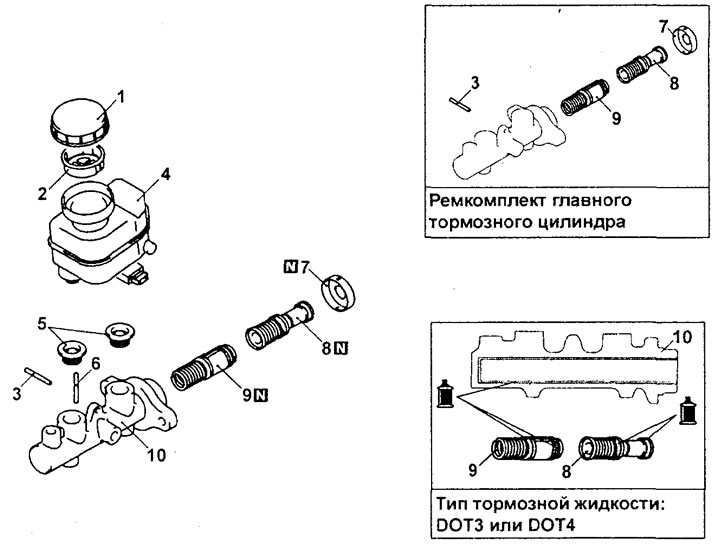

− Removal of parts is carried out in the order of numbers indicated in the figure "Disassembly of the master brake cylinder".

Disassembly of the master brake cylinder. 1 - reservoir cap, 2 - filter, 3 - pin, 4 - brake hydraulic reservoir, 5 - sealing sleeve, 6 - pin, 7 - holder, 8 - primary piston assembly, 9 - secondary piston assembly, 10 - main body brake cylinder.

− When removing parts, pay attention to the procedure for removing the piston retaining ring.

Remove the retaining ring while pressing the piston.

− Installation of parts is carried out in the reverse order of removal.