Removal and installation

− Removal of parts is carried out in the order of numbers indicated in the figure"Removing the wheel speed sensor".

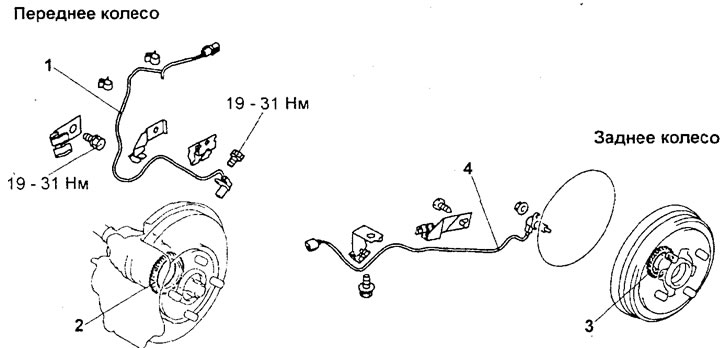

Removing the wheel speed sensor. 1 - front wheel speed sensor and wire, 2 - front wheel speed sensor rotor, 3 - rear wheel speed sensor rotor, 4 - rear wheel speed sensor and wire.

Note: The wheel speed sensor rotor mounted on the drive shaft is part of the shaft and cannot be replaced separately.

− Pay attention to the operation to remove the wheel speed sensor.

Caution: Be careful when handling the wheel speed sensor pole piece and the toothed surface of the rotor so as not to damage them with other parts.

− Installation of parts is carried out in the reverse order of removal.

− After completing the installation of the parts, check the operation of the ABS system and the signal voltage of the wheel speed sensor.

Examination

1. Check the wheel speed sensor.

A) Check that there are no metal particles on the sensor pole piece surface and clean the pole piece surface if necessary.

Note: Since a magnet is installed inside the speed sensor, the pole piece of the sensor is magnetized, as a result of which foreign metal particles are easily attracted to it.

b) Check that the sensor pole piece is not damaged; if damage is found, replace the sensor.

Note: If the pole piece of the sensor is damaged, the sensor will not be able to correctly detect the wheel speed.

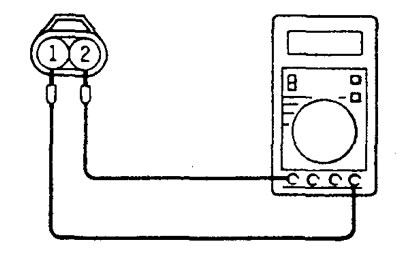

V) Measure the resistance value between the wheel speed sensor terminals.

Rated value - 1.24 - 1.64 kOhm

Note: If the resistance of the wheel speed sensor is out of specification, replace the sensor.

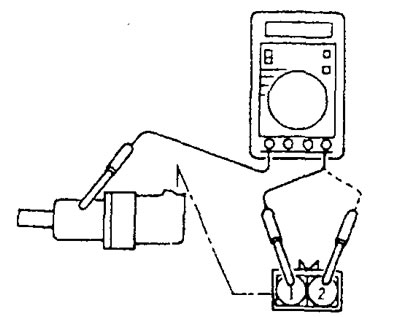

G) Disconnect the connector from the wheel speed sensor and then measure the resistance value between the terminals one by one "1", "2" and sensor body.

Rated value —— 100 kΩ or more

Note: If the insulation resistance value is out of specification, replace the wheel speed sensor.

d) Check for damage, breakage or poor contact in the sensor wires; if defects are found, replace the sensor.

Note: To check for damage to the sensor wire, remove the wiring clamp from the body, then bend the wire near the bracket and pull it to check if there is a temporary lack of contact.

2. Check the gear rotor of the sensor.

Check for deformation or breakage of the sensor rotor teeth; if defects are found, replace the rotor with a new one.