Removing

Disconnect the earth cable from the battery.

Attention: This erases the data in the electronic memory, for example, the memory of engine defects or the code of the radio receiver. Disconnect the battery only when the ignition is off, otherwise the control unit of the fuel injection device may fail. Before disconnecting the battery, read the instructions in sections "Radio" And "Removing and installing the battery".

Injection engine / diesel engine: Remove the air filter, see point 6.6.

Drain the oil from the gearbox.

Remove the battery and battery holder, see item 23.10.

Detach brace -1-.

Remove shift cables -2- from gearbox. To do this, pull out the cotter pins from the side with pliers. Remove spacers. Detach bracket.

Gasoline engine January 1984 to August 1986: Remove shift rods from gearbox. To do this, disconnect the stabilizer link and remove it with the bushing and washers. Loosen the adjusting bolt of the shift rods after cutting the safety wire. Pull the rods off the box and take them aside or hang them on a wire to the body.

Remove clutch cable -3-.

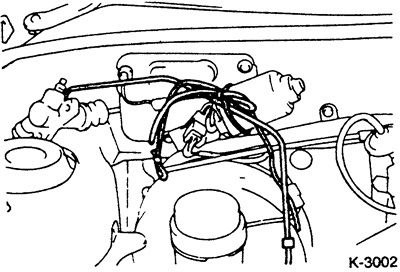

Detach clutch slave cylinder -4- and pipe retainer. Fasten the slave cylinder with the pipe connected to the underbody of the vehicle, see illustration.

Disconnect the reversing light wire -5- from the box.

Loosen union nut for tachometer shaft -6- and pull out flexible shaft.

Remove the starter -7-, to do this, give 2 bolts. Before doing this, disconnect the cable and connector from the starter.

Remove upper mounting bolts -8-; release 9.88 to 3.92: 5 bolts; release from 1.84 to 8.88: 6 bolts. Remove the ground wire from the gearbox, having previously marked its position.

Detach bracket -9- for gearbox

lift the car, see par. 29.

Remove the lower engine compartment tray.

Press the steering rod joints, as well as the axial joints to the steering knuckles, see p. 14.6/16.4.

Pull the drive shafts out of the gearbox, see 14.9.

Secure the removed drive shafts to the body with ropes as far as possible from the gearbox housing.

Disconnect the clutch basket cover.

Remove the lower gearbox mounting bolts.

Vehicles from 1.84 to 9.88: Loosen the box mount bolt. Remove the plug from the inside of the right wheel arch and remove the box mount.

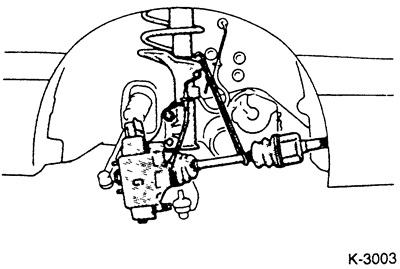

Support the gearbox with a jack. Press the gearbox from the engine with a pry bar, move it to the right and lower it to the ground.

Attention: Place the jack on as large a surface as possible and do not forget to lay wooden spacers.

Installation

Before installing the gearbox, check the clutch and clutch release bearing, see point 11.1.

Clean input shaft splines and lubricate lightly with MOLY paste or MOLY spray.

Caution: If too much grease can get on the surface of the clutch discs during work and cause malfunctions.

Insert the gearbox into the engine compartment in the reverse order of removal.

If, when installing the gearbox, the input shaft of the gearbox does not jump into the clutch disc, the assistant should turn the engine crankshaft slightly. To do this, rotate the front wheel with the gear engaged or, with the gearbox in neutral, turn the crankshaft slightly at the pulley center bolt.

Straighten the gearbox. Most vehicles have guide pins on the engine flange, they must fit into the holes in the clutch housing.

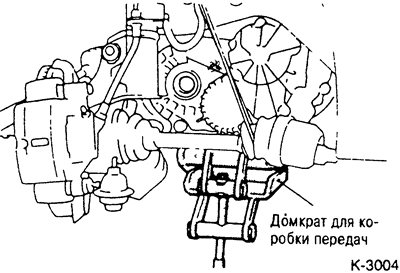

Finally, insert all mounting bolts and tighten evenly, securing the gearbox to the engine. The tightening torque depends on the outside diameter of the bolt. With an outer bolt diameter of 10 mm, the tightening torque is 35 Nm, with a diameter of 8 mm, the tightening torque is 10 Nm.

Attention: In this case, in no case should the box be pulled to the engine by tightening the mounting bolts. All bolts must first be tightened evenly and then tightened using a torque wrench.

Vehicles from 1.84 to 9.88: Install gearbox. Tighten the box hanger bolt. Insert the cover cap on the inside of the right wheel housing.

Install clutch cover and tighten to 10 Nm.

Install drive shafts see 14.9.

Install the tie rod joints and axle joints, see p. 14.6/16.4.

Install the engine bottom pan.

lower the car, see par. 29.

Install gearbox bracket -9-.

Attach the mass cable to the box.

Insert the starter and tighten the two bolts to 30 Nm. At the same time, fasten the cable holder with the lower bolt.

Connect cable and connector to starter.

Insert the tachometer shaft into the gearbox and tighten the union nut.

Connect the reversing light wire to the box.

Install the clutch slave cylinder to the gearbox housing. Tighten the bolts to 20 Nm. Install the hydraulic connection in the box holder.

Install clutch cable.

Put shift cables on the gearbox levers, put spacers, secure with new cotter pins. Adjust gear shift if necessary.

Gasoline engines from 1.84 to 8.86: Insert the gearshift rod into the gearbox, tighten the adjusting bolt with a force of 30 Nm and secure with wire. Position the stabilizer link with bushing and spacers and secure with a force of 65 Nm.

Attach stretch -1-.

Install the battery see item 23.10.

Pour oil into the gearbox.

Fuel injection engine / diesel engine: Install air filter see point 6.6.

Connect the ground cable to the battery.

If available, set the time on the clock and enter the security code into the radio.

Check the operation of the shift lever.

Check the functioning of instruments and indicators.

Check wheel alignment as soon as possible.

Gearbox mount

Vehicles from 1.84 to 8.88*