Mark the position of the drive disk on the engine flywheel with a felt-tip pen or a marker.

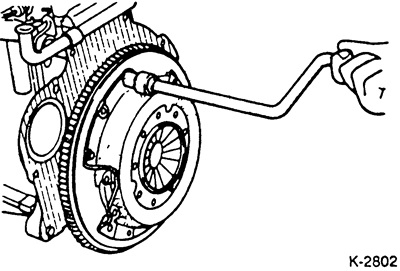

Stop the engine flywheel by inserting a screwdriver or a metal rod into the teeth of the crown so that the flywheel cannot turn when the bolts are loosened.

Sequentially, diagonally, each time 1-2 turns, unscrew the bolts securing the driven disk until the drive disk springs are released.

Caution: If all bolts are removed at once, the diaphragm springs may be damaged.

After that, unscrew the mounting bolts.

Pull out the master and driven discs.

Attention: Take out carefully, not allowing the drive and driven discs to fall, otherwise, after installation, malfunctions may occur due to the separation of the discs and jerks when the clutch is engaged.

Wipe the engine flywheel with a cloth soaked in gasoline.

Caution: The clutch disc must not be cleaned. Do not remove oil residues with detergents.

Examination

Replace oily or mechanically damaged clutch discs.

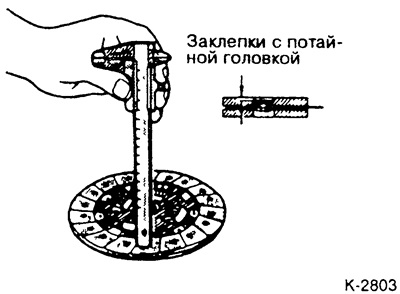

Measure the thickness of the driven disc lining with a vernier caliper. The dimension to the heads of the rivets must be at least 0.3 mm, otherwise the driven disk must be replaced. The same with scratches on the overlays.

Check torsion springs for play and damage, replace clutch disc if necessary.

Slide the clutch disc onto the transmission drive shaft and check that there is no slip or play in the direction of rotation. To do this, put the disk on the shaft of the box and move it with your fingers in different directions. With a play of more than 0.4 mm, there is wear on the splines. As a rule, this applies to the splines of the clutch disc.

Move the clutch disc in both directions along the axis. If heavy play is found, replace the clutch disc or possibly the transmission drive shaft.

Check the driven disc for cracks and scratches.

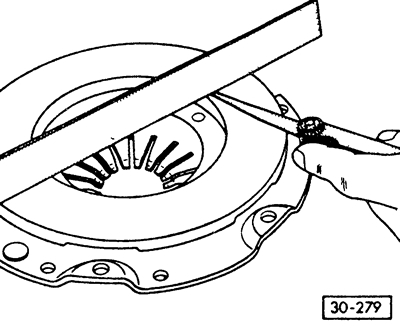

Check the height position of the drive disc diaphragm springs. If the difference in height is more than 0.5 mm, replace the drive disc.

Make sure that there are no cracks in the springs connecting the drive disk to the cover, as well as that the rivets are securely seated. Replace clutch with damaged or loose rivets.

Check the contact surface of the drive plate for cracks, burn marks and wear. Drive discs with an inward deflection of up to 0.3 mm can still be used. Measure using a ruler and a set of probes.

Installation

Treat the driven disk and engine flywheel with very fine sandpaper.

Remove corrosion from driven disc spline and coat with a very thin coat of MoS grease2. Put the grease into the grooves of the splines and distribute evenly with a brush.

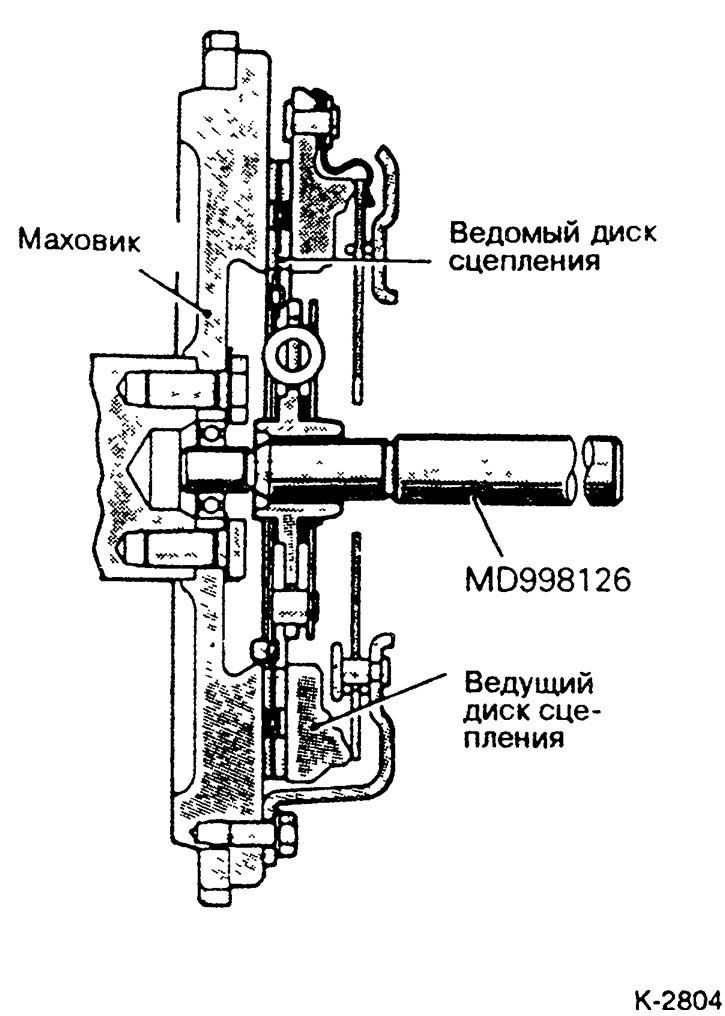

Attach the driven and driven clutch discs to the flywheel. In this case, the flat part of the hub of the driven disk must be turned towards the gearbox, see figure. Center the driven disc relative to the drive disc by eye. However, it is better to center the discs using a special rod, such as HAZET, or an old gearbox input shaft. If the driven disc is not centered, it is not possible to insert the gearbox shaft.

If the old clutch disc is reinstalled, observe the markings made during removal.

Tighten the clutch drive plate mounting bolts.

Sequentially, diagonally, every time for 1-2 turns, tighten the clutch drive plate mounting bolts until the drive plate is tightened. Then remove the centering rod.

Attention: Make sure that when tightening the fastening bolts, the drive plate enters the flywheel evenly and without scoring. Tightening torque of the clutch drive disc bolts: 20 Nm.

Remove the blocking tool from the flywheel crown.

If removed, install release bearing.

Install the gearbox see point 12.1.