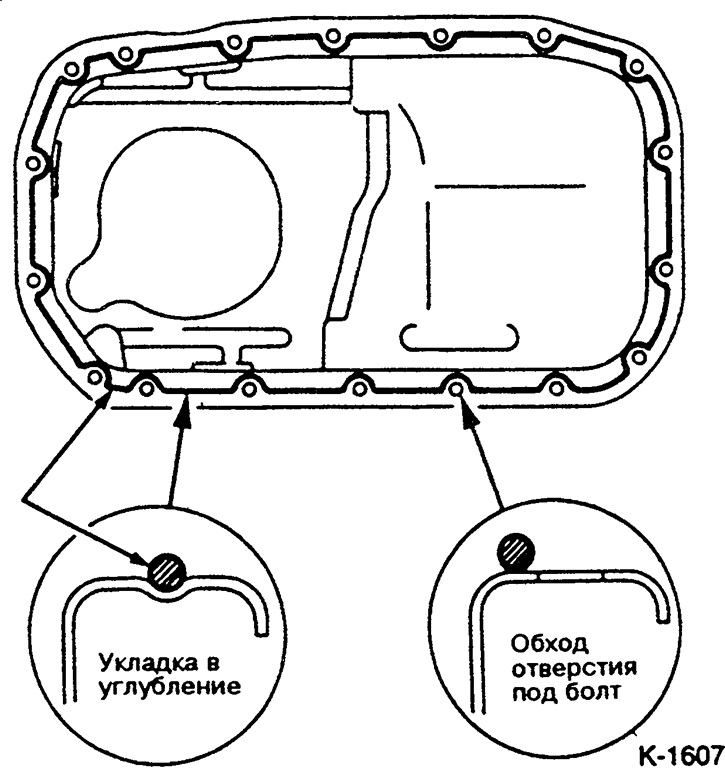

Caution: Do not apply too much sealant and be especially careful around the bolt hole areas. After applying the mass, the parts must be assembled within a quarter of an hour. If this time is exceeded, remove the sealant layer and apply a new one.

Removing

Disconnect the earth cable from the battery.

Attention: This erases the data in the electronic memory, for example, the memory of engine defects or the code of the radio receiver. Disconnect the battery only when the ignition is off, otherwise the control unit of the fuel injection device may fail. Before disconnecting the battery, read the instructions in sections "Radio" And "Removing and installing the battery".

Raise the vehicle, see point 29.

Drain engine oil, see item 32 1

Unscrew the fixing bolts of the oil pan.

Attention: On a 16 valve engine, mark the bolt holes with a length of 10 mm.

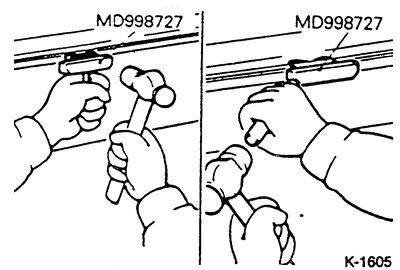

Cut the sealing mass between the engine block and the oil pan. The workshop uses tool MD-998727 for this, which is wound between the engine block and the oil pan.

If a special tool is not available, an old knife can also be used. Carefully insert the knife between the engine block and the oil pan with hammer blows.

Caution: Never pry off the oil pan with a screwdriver or chisel before the seal has been cut. When removing the sump, take care not to damage the sealing flange of the sump.

Remove the oil pan.

When removing the oil pan, it is recommended to unscrew the oil receiver and clean it with a cold cleaning agent. Check the oil receiver screen for damage, e.g. breaks, replace if necessary.

Installation

Carefully clean the mating surfaces of the oil pan and engine block from the sealing material with a straight scraper and a razor blade.

Thoroughly wipe the engine block, crankshaft and oil pump. Otherwise, the sump seal may be damaged by dripping oil.

Install the oil receiver with a new gasket and tighten to 20 Nm.

Wipe the mating surfaces of the oil pan and engine block with a degreaser. Alcohol or acetone can be used as a cleaning agent.

Attention: Do not use detergents that are aggressive towards painted surfaces.

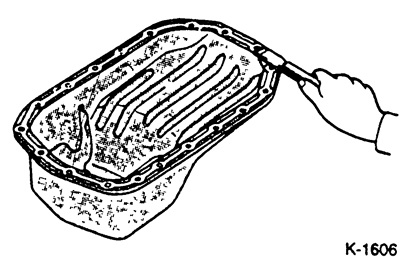

Sealing agent - as shown in the figure - apply in the form of a cord with a diameter of 4 mm along the entire contour of the mating surface of the oil pan. At the same time, lay the sealant cord between the bolt holes in the recess of the oil pan (bottom left picture). The lower right drawing shows the stroke of the bolt hole.

Attach the oil pan to the engine block. Tighten the bolts first by hand and then crosswise to 7 Nm.

Attention: On a 16-valve engine, insert 10 mm bolts into the marked holes. (Front side of the oil pan in the direction of the V-belt).

Lower the car.

Fill with engine oil.

Connect ground cable to battery.

If available, set the time on the clock and set the radio's security code.

Carry out a test drive, check the oil level and check the tightness of the oil pan, possibly carefully tighten all the bolts.