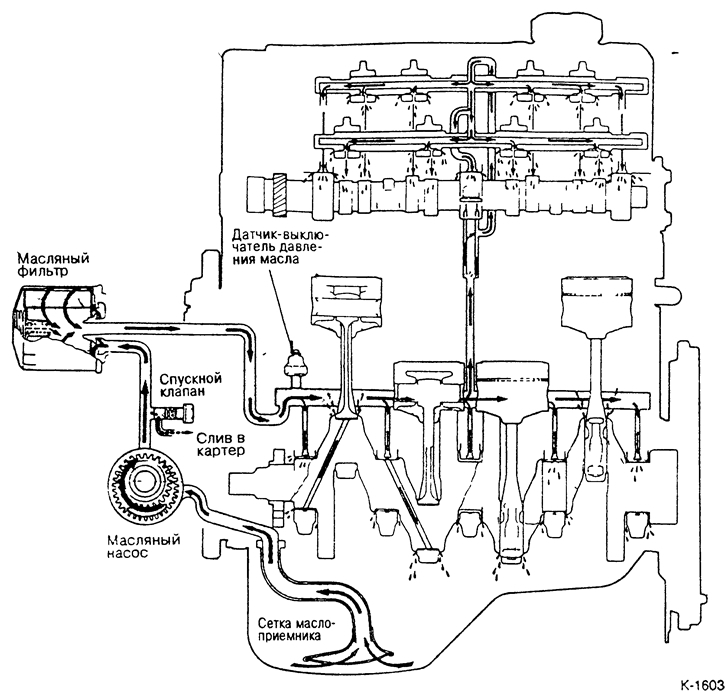

All MITSUBISHI COLT/LAN-CER engines are equipped with a so-called pressure lubrication system. The oil pump draws oil from the oil sump through the oil receiver screen and pushes it through the oil filter into the main oil circuit. There is a drain valve at the outlet of the oil pump (oil pressure control valve). When the oil pressure rises above 5.6 bar, the valve opens and part of the oil flows back into the oil pan.

The oil enters the main circuit along the central axis of the filter cartridge. There is also an oil pressure switch that alerts the driver when the oil pressure is too low by illuminating a warning light on the dashboard. The oil pressure warning lamp comes on when the oil pressure drops below 0.3 bar. When the oil filter is clogged, the bypass valve opens allowing unfiltered oil to pass into the main passage.

Lubrication channels for crankshaft bearings branch off from the main channel. Through inclined holes, oil is supplied to the connecting rod bearings.

At the same time, oil rises through an inclined channel into the cylinder head and lubricates the camshaft bearings, rocker arms and valve stems there.

The oil pump on a gasoline engine is mounted in one housing together with the crankshaft oil seal on the side of the engine timing belt. The inner rotor of the oil pump is connected to the crankshaft. Structurally, the oil pump was produced until July 1988 as a pump with a gear with internal teeth, and from August 1988 as a rotary pump. In a diesel engine, the gear oil pump is located at the front of the engine.

On some COLT / LANCER models, an oil cooler is additionally installed (side circuit radiator). In this case, part of the oil flow after the oil pump branches off to the oil cooler located in the nose of the vehicle. It serves to better cool the oil and thus the engine.