Connect to the fuel pump control terminal with a wire plus the battery. In this case, the fuel pump should work.

By compressing the fuel hose between the fuel filter and the splitter, check if the hose is pressurized.

Noises of pumped fuel should be heard.

If pressure and noise are not felt, check the wiring according to the electrical diagram.

If the electrical connections are in order, especially the supply voltage at the relay and the control unit, and no pressure is still felt during the test, the fuel pump should be replaced.

Pressure test

16 valve engine: Remove throttle body support.

Connect an appropriate fuel pressure gauge between the fuel supply hose and the fuel splitter.

Attention: When opening the fuel circuit, plug the opening of the hose with a rag so that fuel does not leak out due to residual pressure. Be sure to release the pressure first see point 8.3.

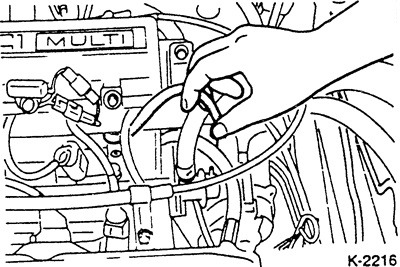

Connect the positive terminal of the battery to the control terminal of the fuel pump using an auxiliary wire, as shown in fig. K-2214, and let the fuel pump run. Check the tightness of the pressure gauge connection.

Disconnect auxiliary wire. Start the engine and let it idle.

Check fuel pressure. The required value is 2.7 bar.

Disconnect the vacuum hose from the fuel pressure regulator and plug the hole in the hose with your finger. The fuel pressure should now be between 3.3 and 3.5 bar. Reconnect the vacuum hose.

Add gas several times. While doing this, lightly press the return hose with 2 fingers and thus determine whether the fuel pressure increases.

Attention: If the amount of fuel is too low, when gas is supplied to the engine, the pressure increase in the return hose is not felt.

If the fuel pressure is low, or if no increase in pressure is felt in the return hose, replace the fuel filter and repeat the test.

Another reason may be that the fuel pressure regulator is leaking in the fuel outlet direction. In this case, the pressure regulator must be replaced.

If the fuel lines are not kinked or frayed (visual inspection), replace the fuel pump.

The fuel pressure may be too high if the pressure regulator is stuck or the return hose is clogged. Clean hose or return tube or replace, otherwise replace pressure regulator.

If the fuel pressure remains constant with the vacuum hose disconnected and connected, replace the vacuum hose or check that the connection nipple is not clogged.

After checking the pressure, stop the engine and check the pressure retention. The pressure should not drop within 2 minutes.

If during this time the pressure slowly decreases, either the fuel pressure regulator is leaking or the injection valve is leaking.

If the pressure drops quickly, then the fuel pump check valve is usually defective. In this case, replace the fuel pump.

Relieve pressure in the fuel system, see point 8.3.

Disconnect the pressure gauge, while laying a rag at the connection points.

Connect the fuel pressure hose with a new O-ring.

16 valve engine: Attach throttle body support

Switch on the fuel pump and check the tightness of the connections.