A diesel engine does not need an ignition system, because in the presence of a high compression ratio, the intake air heats up so much that, after fuel injection, it ignites by itself.

Depending on the year of manufacture and type of engine, there are various types of ignition systems in operation:

- January 1984 to August 1988: Mechanical interrupter or transistorized ignition system.

- From September 1988 to March 1992: Carburetor engines are equipped with a transistorized ignition system with mechanical ignition timing. The 1.5L engine with fuel injection has an electronically controlled ignition system.

- On 16-valve engines, a crankshaft position sensor is installed instead of a distributor. The electronic control unit calculates the ignition moment from the signals of the sensors and in accordance with the characteristics embedded in it and generates a spark through two ignition coils.

In mechanically controlled ignition systems, an interrupter is installed in the ignition distributor, which has the task of inducing ignition voltage in the ignition coil at the moment of interruption of the primary current.

The ignition voltage created in the ignition coil is fed through the distributor runner and ignition wires to the corresponding spark plug. A spark forms between the electrodes of the spark plug, which ignites the air-fuel mixture in the combustion chamber of the cylinder. The ignition timing should be automatically shifted in the direction of the ignition advance when the engine speed is increased. This correction of the ignition timing occurs in ignition systems with mechanical control in the ignition distributor using inertial weights and vacuum (vacuum hose from intake pipe to ignition distributor).

In transistorized ignition systems, the ignition spark is generated by a signal from a proximity sensor installed in the ignition distributor. Correction of the moment of ignition is also carried out with the help of inertial weights and vacuum.

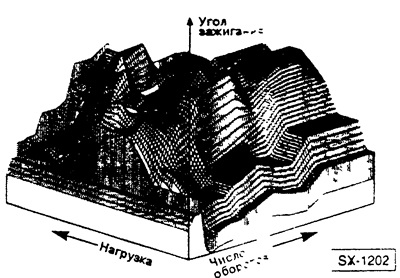

For a 1.5 liter engine with a fuel injection device, the ignition timing is corrected by a single electronic control unit for the ignition system and the fuel injection system. According to the characteristic stored in the memory of the block - see figure - the control unit sets the optimal ignition timing depending on the engine speed and load. In addition, the calculator controls the ignition process itself. The task of the ignition distributor here is to apply the ignition voltage to the individual spark plugs in a predetermined sequence.

16 valve engines have a distributorless ignition system. The distribution of the ignition voltage is carried out here by the electronic control unit for the ignition and injection systems. The crankshaft position sensor, driven by the intake camshaft, provides the electronic control unit with information about the engine speed and the position of the crankshaft. On engines with a fuel injection device, a knock sensor is installed on the engine block approximately between the 2nd and 3rd cylinders. It detects the occurrence of knocking in the engine and notifies the electronic control unit using voltage fluctuations to shift the ignition timing in the direction "later". Timing offset prevents knock ignition and thus avoids engine damage.

Caution: When working on the ignition system, precautions must be observed.