Checking with a special closing angle measuring device

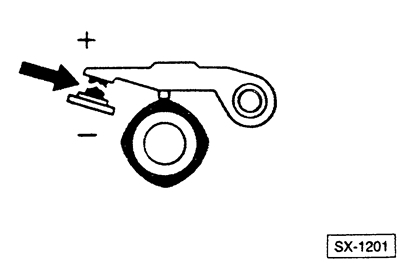

Connect the measuring device in accordance with the manufacturer's operating instructions.

Crank the engine with a starter or start it at idle. Take the instrument reading.

The closing angle must be 52°± 6°degrees. If the measured value is out of tolerance, adjust the closing angle.

Adjustment with special closing angle measuring device

Using a screwdriver, fold back the retaining clips on the side of the ignition distributor and remove the distributor cover.

Lay the distributor cap aside in such a way that any spark that may have formed is reliably discharged to the ground and cannot reach the body.

Loosen, without unscrewing, the fixing screw -2- (pic. G-1205).

Set the gearbox to neutral, cock the handbrake. Have an assistant turn the engine over with the starter and set the desired closing angle by shifting the contact pad of the breaker contact.

If the closing angle is too small, the distance between the distributor cam and the hammer should be reduced, if the angle is too large, the distance should be increased.

After setting the desired angle, tighten the fixing screws and check the closing angle again. If it is out of tolerance, repeat the adjustment.

Adjustment with a set of probes

If there is no special measuring device, as a temporary measure, the setting of the closing angle can be made using a set of probes. Subsequently, you will have to check the value of the closing angle using a special measuring device and possibly adjust.

Remove the ignition gel distributor cap and remove the distributor slider.

Engage 4th gear and move the vehicle on a level surface and either crank the engine by the crankshaft pulley until the plastic breaker contact slider contacts the highest point of the distributor cam. With a correctly set gap, the probe should pass tightly between the contact surfaces. The gap should be 0.45-0.55 mm, otherwise it should be adjusted.

In this case, when adjusting, one should strive for the smallest allowable value.

Attention: With burnt contacts, measure the gap only along the edge - in the middle of the measurement are distorted due to the presence of bumps on the surface of the contacts.

If the clearance does not correspond to the admissible values: Slightly loosen the screws -1- and -2- (do not twist), see fig. G-1205. Slightly move the contact pad of the breaker contact with a screwdriver until the probe is tight between the contact surfaces.

After setting the required value, tighten the fixing screws.

Attention: Since the setting with a set of feeler gauges is not accurate, subsequently check the closing angle with a special measuring device.

Put the boot and the distributor slider on the distributor axle, while the slider protrusion should enter the recess on the axle.

To put on a cover of the distributor of ignition and to throw on both holding brackets.

Set ignition timing.