A defective injector can be identified by loosening the union nuts in succession at high idle. If the number of revolutions does not change after loosening the union nut, this indicates that the corresponding injector is defective. The injector can be checked with a pressure gauge. (Workshop work; required injection pressure: 120-130 bar). The first signs of a malfunction of the nozzle appear as follows:

- false ignitions

- detonation in one or more cylinders

- engine overheating

- engine power reduction

- excessively strong black exhaust

- increase in fuel consumption.

Removing

Carefully clean the outside of the injection pipe and fuel return pipes with a cold cleaner or diesel fuel.

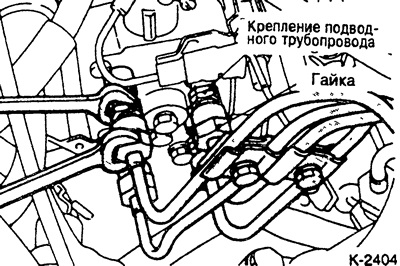

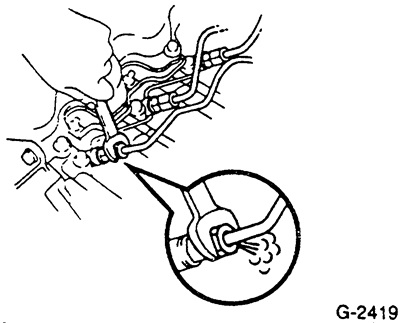

Remove the injection pipeline as a set, to do this, loosen the union nuts on the pump and nozzles with a wrench. At the same time, hold the fastening of the underwater pipeline and the fastening of the nozzles with a wrench.

Attention: Do not disturb the shape of the bend.

Attention: After unscrewing the underwater pipeline, plug the holes with suitable plugs to prevent dirt and foreign objects from getting inside.

Disconnect the fuel return hose.

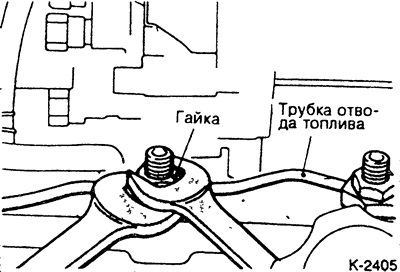

Remove the fuel return pipe nuts.

Attention: When doing this, hold the hexagon of the tube with a wrench, otherwise it can be bent or broken.

Remove the fuel return pipe.

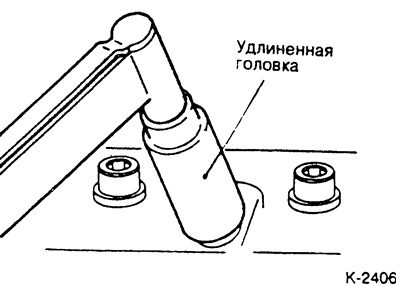

Unscrew the nozzles with the help of an elongated head and fold them in the same order as they were removed. If necessary, you can mark the nozzles with adhesive tape in order to install them in their original places.

Cover the holes for the nozzles so that foreign objects cannot get there.

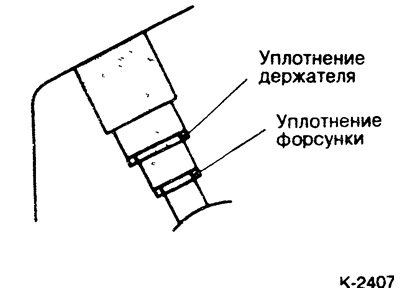

Each hole has a holder seal and a nozzle seal. They must be replaced.

Attention: Never treat the nozzle and nozzle needle with wire, needle file or sandpaper. Do not mix up parts of different nozzles.

Installation

Clean the injector holes and insert 4 new holder seals and injector seals into them.

Fit injectors and tighten to 60 Nm.

Attention: Overtightening of the holder can lead to deformation of the injector and thus to hanging of the injector needle or other damage.

Fit the fuel return pipes with 4 new gaskets and tighten the nuts to 40 Nm.

Attention: When doing this, hold the hexagon of the corresponding tube with a wrench.

Install injection line and tighten nuts to 35 Nm. While doing this, hold the pipe holders or nozzle holders with a wrench.

Attach the pipe bracket.

Slightly loosen the union nuts of the injection pipes on all nozzle holders.

Crank the engine with the starter until diesel fuel appears at the injection pipes. Tighten the injection pipes to the prescribed torque. If necessary, bleed the air from the fuel system using a hand pump, see point 32.1.