Check condition: the battery must be fully charged, the battery voltage must be at least 12 V. The engine is cold (ambient temperature) or the engine temperature must not exceed 55°C. At higher temperatures, disconnect the coolant temperature sensor connector.

Checking the power supply

This test can be carried out without removing the glow plugs.

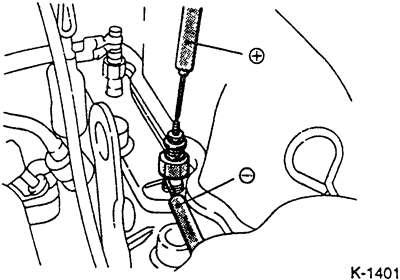

Connect the voltmeter to the current bus of the glow plugs and the spark plug body.

Turn on the ignition. Warm up the engine (preheat). The voltmeter should show battery voltage for about 3 seconds (9 V and above). The time depends on the temperature of the glow plug and on the voltage of the battery.

Start the engine and let it idle. During start-up and after that for approximately 180 seconds, the voltmeter should indicate battery voltage (9 V and above).

If there is a power failure, have the preheat control unit checked by a specialist workshop.

Checking glow plugs

Check current bar for corrosion, otherwise clean or replace.

Check the glow plug for external visible damage.

Remove the connection cable and current bar.

Use an ohmmeter to measure the resistance between the glow plug contact and the spark plug body. Required value: about 0 ohm. If the resistance is equal to oo, replace the spark plug.

Check all glow plugs in the same way.

Attention: The normal resistance of a plug is very small and difficult to measure with conventional ohmmeters. Required value: 0.235 ohm. Before measuring, clean the candle from oil.

Connect wire and bus bar.

If it was disabled, reconnect the coolant temperature sensor connector.

Attention: If no defect is found, although the engine continues to be difficult to start, visually inspect the glow plugs during warm-up. To do this, remove the injectors and observe the glow plugs through the holes.

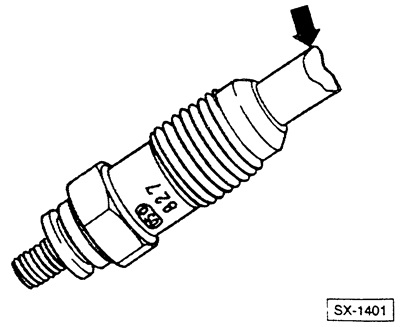

Glow plugs with burnt heating rods

Burning of glow plugs is often the result of defective injectors. Such damage should not be attributed to an internal or external defect in the glow plug.

If such glow plugs -arrow- are found, it is not sufficient to replace them. In this case, it is also necessary to check the injection nozzles for injection pressure and tightness (workshop work).