8 and 12 valve petrol engines

Attention: Depending on the model and year of manufacture, it is necessary to remove additional adjacent units, such as the generator, servo pump and air conditioning compressor.

Removing

Disconnect the upper engine mount while supporting the engine, see point 1.4.

Loosen the water pump pulley by lightly pressing the V-belt with your hand so that the pulley does not turn.

Remove the V-belt see paragraph 1.21.

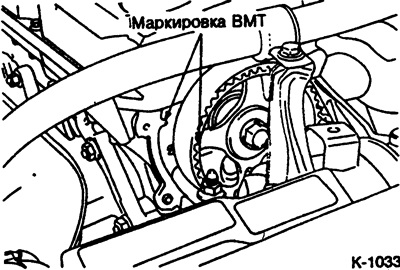

Set the crankshaft to the TDC of the 1st cylinder and no longer knock down the installation.

Installing the engine at TDC of the 1st cylinder

Note: At TDC, the piston was in the cylinder at its highest point. The piston occupies this position in the compression and exhaust strokes. The TDC position on the compression stroke is called the ignition TDC position, since during normal engine operation, ignition occurs shortly before this.

Remove upper toothed belt cover.

Turn the crankshaft of the engine clockwise until the camshaft reaches the TDC position.

The motor shaft can be rotated in several ways:

1. Raise the car from the front on one side. Engage fifth gear, cock the handbrake. Turn raised front wheel. This rotates the crankshaft of the engine. An assistant is required to turn the wheel.

2. Place the car on a level ground. Engage fifth gear. Move car.

3. Turn the crankshaft at the center bolt of the crankshaft pulley. Before doing this, set the gearbox to neutral and apply the handbrake.

Attention: Do not rotate the engine by the camshaft belt gear bolt. In this case, the toothed belt is overloaded.

Crank the engine until the marking on the camshaft gear matches the TDC mark on the cylinder head. In this case, the engine is set to the TDC position of the ignition of the first cylinder.

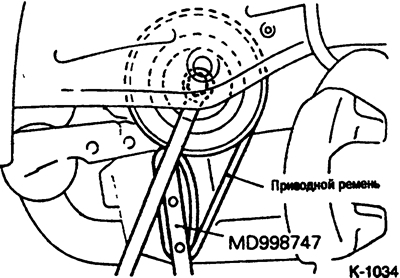

Disconnect the crankshaft pulley from the crankshaft. To keep the crankshaft from turning in the workshop, fixture MD-998747 is used, as well as an old V-belt.

Caution: The V-belt must not be damaged. Under no circumstances should this belt be reinstalled, as it may be damaged when held against turning. If the device is not available, engage first gear and have an assistant depress the brake pedal.

Remove lower toothed belt cover.

Mark the direction of movement of the toothed belt with chalk or felt-tip pen. The toothed belt moves clockwise.

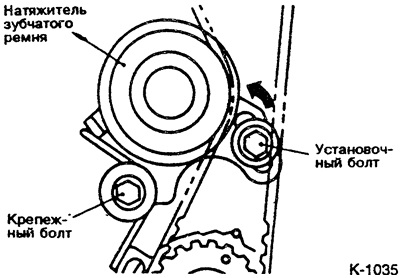

Loosen the toothed belt tensioner set screw.

Press the toothed belt tensioner in the direction of the water pump by hand to loosen the toothed belt tension. In this position, tighten the tie bolt just enough so that the belt tensioner setting does not go astray.

Remove toothed belt.

Attention: Do not knock down the TDC position of the camshaft and crankshaft. If it is necessary to rotate the camshaft with the toothed belt removed, make sure that the crankshaft is not in the TDC position (risk of damage to valves and pistons). To do this, mark the position of the crankshaft gear (apply paint markings on the crankshaft gear and on the engine block). Then rotate the crankshaft wheel ¼ turn (90°) forward or backward.

Checking the condition of the toothed belt

Be sure to replace the toothed belt if the following defects are present:

Traces of oil or coolant on the toothed belt. As a rule, the reason for this lies in the leakage of the oil seals of the housing or camshaft or the leakage of the water pump.

Rubber hardening on the outside of the toothed belt. The belt then becomes shiny, inelastic and so rigid that no trace of a strongly pressed fingernail remains.

Rubber rips on the outside of the belt.

Tearing and peeling of fabric on the inside of the belt.

Gusts at the base of the teeth.

Gusts on the narrow side of the belt.

Severe wear on the narrow side of the belt.

Severe tooth wear. Fraying of the fabric on the loaded side of the teeth. Rubber peeling, color change to white. Reducing the width of the teeth.

Chipped teeth.

Installation

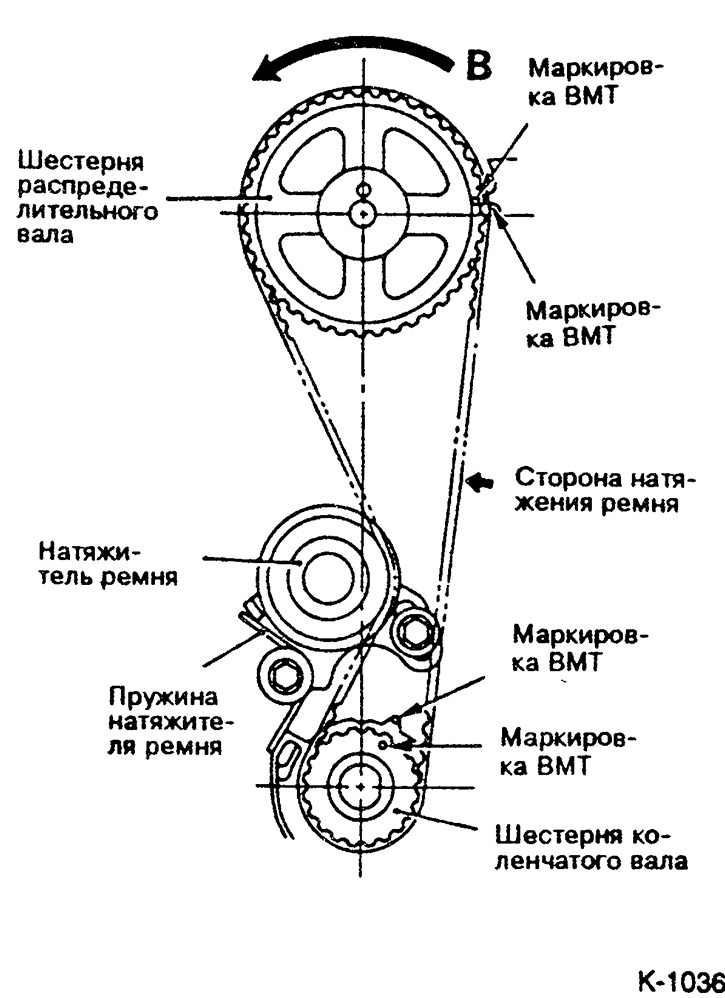

Check the TDC position of the camshaft and crankshaft, adjust if necessary.

Check if the camshaft is in the TDC position of the 1st cylinder. In this case, the marking on the camshaft gear must match the mark on the cylinder head. If not aligned, carefully turn the camshaft without the toothed belt overlaid. In this case, the crankshaft should not be in the TDC position.

Apply toothed belt. When doing so, the direction of rotation marking made during removal must be taken into account. A used toothed belt must only be refitted in the same direction of travel. First put the toothed belt on the crankshaft gear, keep the tension side of the toothed belt taut, then route the toothed belt on the camshaft gear through the tensioner.

Turn the camshaft gear slightly anti-clockwise - direction of arrow B -, thereby tightening the belt on the tension side.

Loosen tensioner pinch bolt.

Temporarily install the crankshaft belt pulley so that the toothed belt does not come off when the crankshaft rotates.

Pull on toothed belt.

Recheck the TDC position of the crankshaft and camshaft. All marks and markings of the TDC with a tensioned toothed belt must match, otherwise it is necessary to remove the toothed belt and repeat the adjustment.

Install the lower toothed belt cover. Longer bolts are installed at the bottom right.

Secure the crankshaft pulley with the central bolt with a tightening torque of 100 Nm. To do this, engage 1st gear, press the brake pedal. Tighten the 4 fixing screws to 15 Nm.

Fasten the water pump pulley with 10 Nm.

Install the V-belt see paragraph 1.21.

Install the upper engine mount, see point 1.4.

Check ignition timing, adjust if necessary.

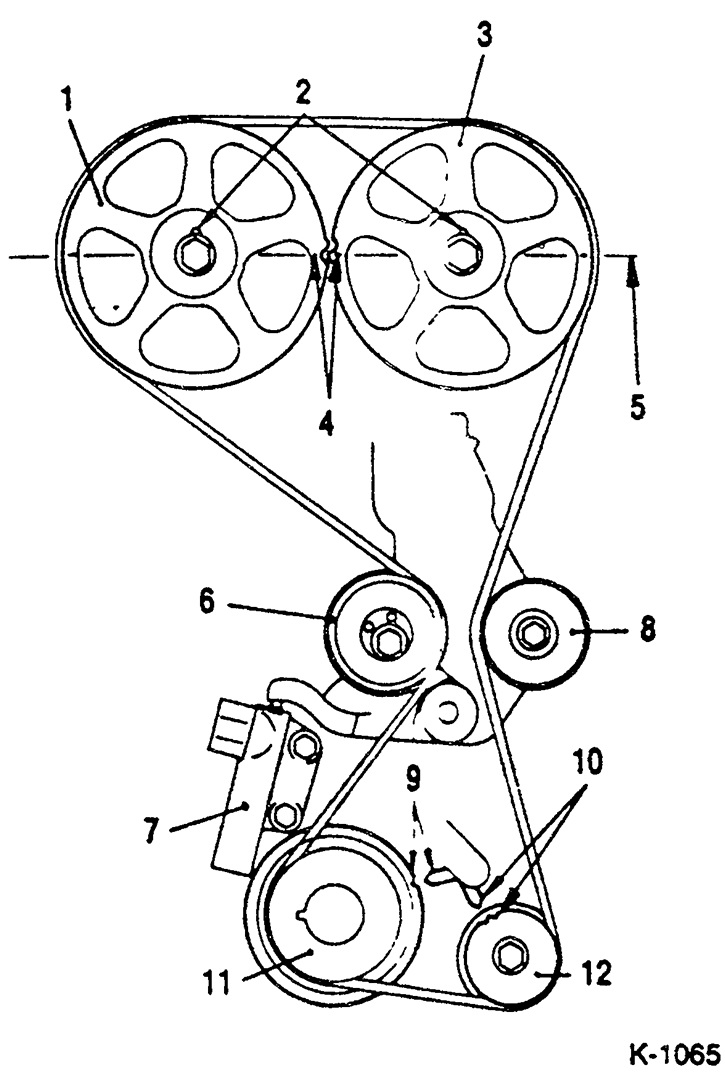

16 valve petrol engine (1.6, 1.8 l)

The 16 valve engine has a hydraulic belt tensioner that maintains a constant belt tension. Adjustment of a tension of a gear belt is made only after removal and installation of a gear belt. Since this work requires a certain amount of experience and a special tool, it should be entrusted to a specialist.

1 - Gear wheel of a camshaft of final valves; 2 - Pin; 3 - Inlet camshaft gear; 4 - Setting mark; 5 - Upper edge of the cylinder head; 6 - Timing belt tensioner; 7 - Toothed belt tensioner; 8 - Timing belt guide roller; 9 - TDC marks; 10 - TDC marks; 11 - Crankshaft gear; 12 - Oil pump gear