Removing

Carburetor engine: Remove the air filter, see point 6.6.

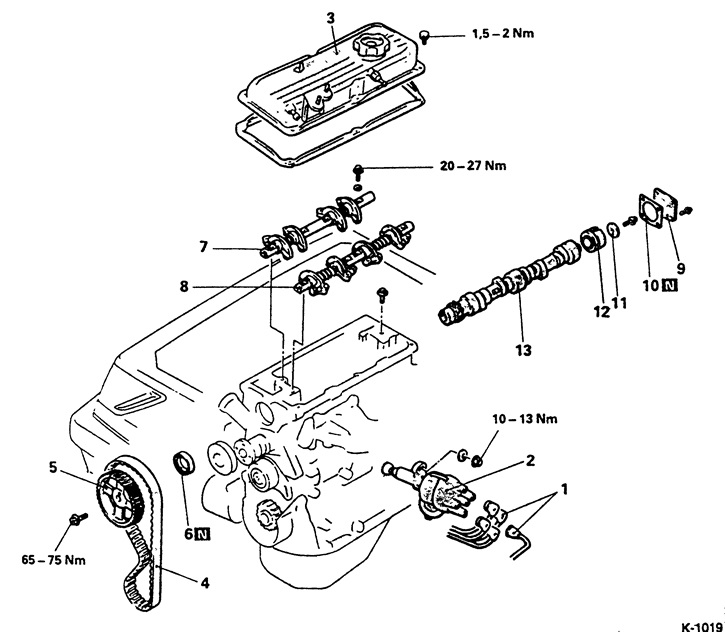

Disconnect ignition cable -1- from distributor cap.

Remove ignition distributor -2-, see point 4.8.

Carburetor engine: Remove the fuel pump, see point 6.4.

Loosen cylinder head -3-.

Remove toothed belt -4-, see point 1.6.

Loosen the camshaft sprocket while holding the sprocket or camshaft from turning. To block the camshaft, it is necessary to insert a massive screwdriver from the side under the rocker arm shaft, so that the shaft spike rests against the screwdriver when the bolt is loosened. The second possibility is also to block the camshaft gear with a pin from the front. To do this, insert a suitable rod or screwdriver into the hole in the gear wheel and rest against the upper edge of the cylinder head. Install a wooden spacer to prevent damage to the cylinder head. While holding a screwdriver, unscrew the camshaft mounting bolt. Remove the gear wheel, if necessary, you can remove it with light blows of a rubber hammer.

Remove oil seal -6-.

Loosen and remove rocker block -7/8-.

Attention: Before doing this, loosen the valve clearance adjustment screws. First, loosen all the fixing bolts of the rocker axles by half a turn, and then slowly and evenly unscrew them.

Up to 8.90: Unscrew rear cover -9- and remove together with gasket -10-.

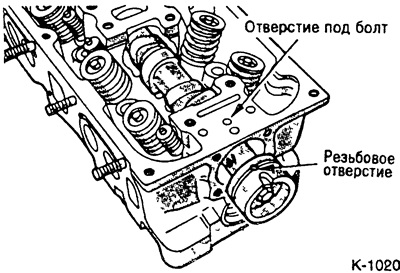

Up to 8.90: Unscrew the fixing bolt through the hole in the cylinder head, see fig. K-1020. 11 - Thrust flange, 12 - Camshaft thrust bearing housing.

Carefully pull out the camshaft through the hole in the cylinder head on the gearbox side.

Installation

Rinse all parts in gasoline, clean mating surfaces.

Before 8.90: Check camshaft end play. To do this, insert a feeler gauge between the thrust bearing housing and the camshaft. Permissible value: 0.05 + 0 20 mm, wear limit. 0.4 mm. If the measured value exceeds the wear limit, replace the thrust bearing housing and repeat the test. If the play still remains large, replace the camshaft.

Lightly lubricate the camshaft and insert it into the cylinder head.

Caution: Be careful not to damage the bearing races when doing this.

Up to 8.90: Insert camshaft with thrust bearing housing into cylinder head. The threaded hole in the camshaft thrust bearing housing must point upwards. Then align the threaded hole with the bolt hole on the cylinder head, insert the bolt and tighten.

Up to 8.90: Screw on the rear cover with a new gasket.

From 9.90: Install the camshaft so that the dowel pin points upwards.

Lubricate the rocker arm block with engine oil, install, tighten the bolts in small portions and finally tighten to 24 Nm (8 valve engine). The tightening torque on a 12 valve engine is 32 Nm.

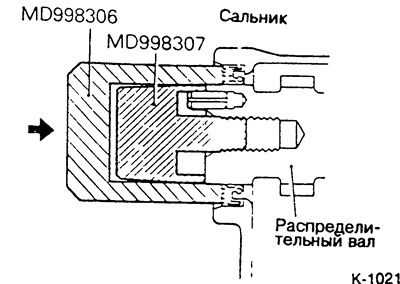

Install the camshaft oil seal using special tools MD-998306/7 To do this, first screw tool MD-998307 into the camshaft Lubricate the surface of the tool with a thin layer of clean engine oil.

Lubricate the sealing lips of the oil seal with engine oil and push the oil seal inward.

With light blows of a hammer on tool MD-998306, drive the oil seal into the cylinder head.

Attention: If special tools are not available, 2 tubes of suitable diameters can be used. Be careful not to damage the seal when installing.

Install and secure the camshaft gear.

Install toothed belt see section 1.6.

Carburetor engine: Install fuel pump with 2 new gaskets, see point 6.4.

Adjust valve clearances see paragraph 1.18.

Install the cylinder head cover.

Install the ignition distributor see point 4.8.

Put the ignition wires on the distributor cap.

Carburetor engine: Install air filter.