Depending on the year of manufacture and on the composition of the equipment, the laying of electrical wires, as well as low-pressure and coolant hoses, can be carried out in the engine compartment in different ways. Since it is impossible to give a detailed picture of each option, it is recommended to mark the wires with adhesive tape before removal, if necessary.

Remove the cylinder head only when the engine is cold (ambient temperature) . The intake and exhaust manifolds remain connected.

A defective cylinder head is identified by one or more of the following:

- Loss of power.

- Coolant leak. Exhaust gases are white when the engine is hot.

- Increased oil consumption.

- Coolant getting into oil. The oil level does not drop, but rises. Gray engine oil, foam bubbles on the dipstick. Liquid oil.

- Engine oil in coolant.

- The coolant boils a lot.

- Lack of compression in two adjacent cylinders.

Removing

Disconnect the earth cable from the battery. Attention: This erases the data in the electronic memory, for example, the memory of engine defects or the code of the radio receiver. Disconnect the battery only when the ignition is switched off, as otherwise the control unit of the injection device may fail. Before disconnecting the battery, read the instructions in sections "Radio" And "Removing and installing the battery".

Drain the coolant see section 3.3.

Disconnect and lay aside the throttle cable.

Remove the crankcase ventilation hose between the cylinder head cover and the thick air intake hose.

Remove the air intake hose between the air filter and thermostat housing. First release and move back the clamps.

Remove the upper coolant hose from the thermostat housing. First release and move back the clamps.

Remove the heater hose from the thermostat housing. First release and slide back the collar.

Remove the coolant connecting hose between the throttle valve element and the coolant pipe branch. First release and move back the clamps.

Disconnect the low pressure hose from the brake booster suction pipe.

Unscrew the subsea fuel line circuit board from the distributor tube. Remove O-ring, install new O-ring when installing. Caution: The system is under high pressure, so be sure to depressurize first, see point 8.3.

Remove the fuel outlet pipe from the pressure regulator at the distribution pipe, first releasing the clamps of the clamps. When removing, place a rag to collect any spilled fuel. If necessary, close the hoses with suitable plugs. Suitable for this are, for example, screws with the appropriate thread diameter. Lay fuel pipes aside, secure to body with wire if necessary.

Remove all spark plug tips and remove the ignition wires from the distributor cap.

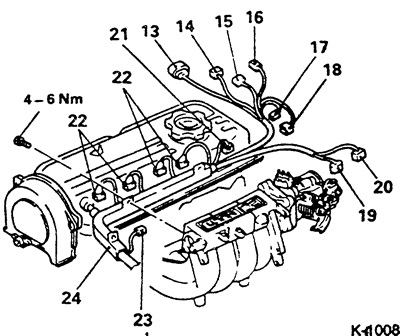

Disconnect all electrical wiring from the cylinder head:

- Distributor connector -13/14-.

- Lambda probe connector -15-.

- Capacitor connector -16-.

- Connector for coolant temperature sender -17-.

- Connector for coolant temperature sensor -18-.

- Position sensor connector -19-.

- Idle speed controller connector -20-.

- Throttle position sensor connector -21-

- Connector for injection valves -22-.

- Noise filter connector.

Optional for 84 HP engine:

- Knock sensor connector.

- Power transistor connector.

- Ignition coil connector.

- Capacitor connector.

Unclip wiring harness -24- from intake manifold and lay to one side.

Note: The following designations refer to Figure K-1009.

Remove upper toothed belt guard -25-.

Remove cylinder head cover -26- with gasket -27-. To facilitate subsequent installation, note the fastening of the clamps on the cylinder head cover.

Set the engine to TDC, see point 1.6.

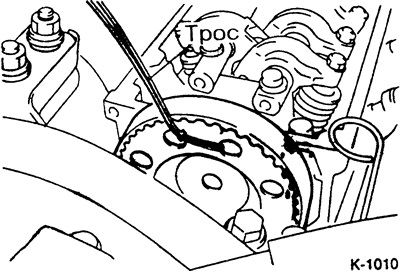

Secure the camshaft sprocket with a cable as shown in the illustration. Unscrew the fixing bolt, while inserting a large screwdriver or rod into the hole of the gear wheel and rest against the cylinder head to prevent the camshaft from turning. Place a piece of wood under the screwdriver to prevent damage to the cylinder head.

Caution: The toothed belt remains on the camshaft sprocket. Make sure that the position of the belt on the gear wheel does not change. With the camshaft gear removed, the shaft must not be moved.

lift the car, see par. 29.

Unscrew front muffler pipe -29-. Lower the muffler and secure it to the body with a wire, see also point 10.

lower the car, see par. 29.

Loosen the intake manifold fitting.

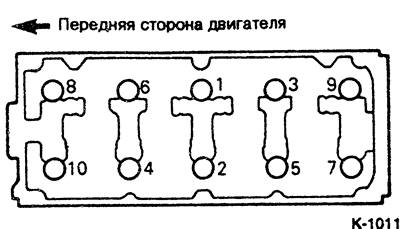

Loosen the cylinder head bolts in the reverse order of tightening, i.e. 10 to 1, see section "Installation". In this case, first unscrew all the bolts by 1/2 turn, and then unscrew them completely.

Check that all wires and hoses suitable for the cylinder head have been removed.

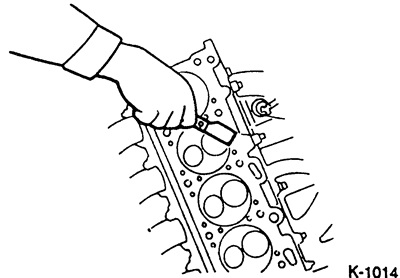

Raise the cylinder head and place it on two wooden blocks.

Remove gasket -31- for front muffler pipe, replace when installing

Remove the cylinder head gasket.

Installation

Before installing, use a suitable scraper to carefully remove the remaining seals from the cylinder head and engine block. Make sure that dirt does not get into the holes of the block. Close the holes with a rag.

Check for oil in the cylinder head bolt holes. If there is, be sure to remove it. To do this, insert a clean rag into the holes and blot the oil.

Attention: If there is oil in the holes, the engine block may be damaged when the bolts are tightened.

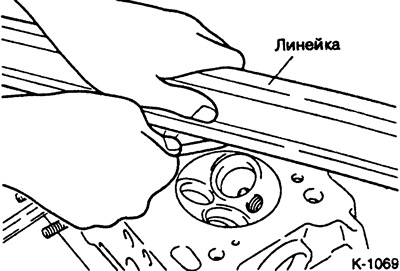

Check the misalignment of the cylinder head and engine block with a steel ruler.

Check with a steel ruler and a set of feelers for misalignment in various places of the cylinder head (motor block). Flatness should not exceed 0.2 mm (at the motor block 0.1 mm).

Caution: When machining the surfaces of the cylinder head, the permissible minimum height must not be exceeded, see paragraph 1.17.

Be sure to replace the cylinder head gasket.

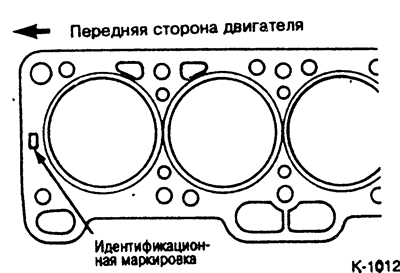

Apply the cylinder head gasket without sealant so as not to block the holes. The identification marking must face up, towards the cylinder head.

Install a new gasket on the front muffler pipe.

Install the cylinder head. Make sure that the camshaft is in the TDC position of the 1st cylinder, see point 1.6.

Screw in 10 cylinder head bolts with washers by hand. The cylinder head bolts must be replaced.

Attention: The tightening of the cylinder head bolts must be carried out with great care. Before tightening, the accuracy of the torque wrench must be checked. Tighten the cylinder head bolts with a cold engine.

Tighten the cylinder head bolts in 4 passes. With each pass, tighten the boots in order from 1 to 10.

Tightening procedure for cylinder head bolts for a 1.5L engine from August 1990

Engine 55 + 84 hp release since January 1984

- 1st pass: with 20 Nm torque wrench.

- 2nd pass: with 40 Nm torque wrench.

- 3rd pass: with 60 Nm torque wrench.

- 4th pass: with 75 Nm torque wrench.

Caution: Do not retighten the cylinder head bolts when the engine is hot, as part of a service or after a repair.

Secure muffler with new nuts.

Slide the gear wheel with toothed belt onto the camshaft and secure. Make sure that the camshaft and crankshaft are in the TDC position and the position of the toothed belt on the gear wheel is not lost, the TDC position see point 1.6.

Fit a new cylinder head cover gasket, fit the cylinder head cover and lightly tighten the bolts alternately.

Install the upper toothed belt cover.

Tighten the intake manifold fitting with a force of 25 Nm.

Check coolant, oil and low pressure hoses for porosity and ruptures, replace if necessary.

Put on all low pressure hoses, tighten with clamps, see section "Withdrawal".

Route the cable harness and secure it to the intake manifold.

Connect all electrical wires to the motor, see section "Withdrawal".

Install and secure the fuel supply pipe with a new O-ring. Moisten all joints with gasoline first. When reassembling, be careful not to pinch or damage the O-ring.

Put the fuel outlet pipe on the distribution pipe and secure with a clamp.

Connect the throttle cable to the throttle valve element and secure to the intake manifold.

Install the ignition wires see point 4.4.

Put on the low pressure hose of the hydraulic vacuum brake booster and secure with a clamp.

Put on the coolant and heater hoses and secure with clamps, see section "Withdrawal".

Put on the air intake hose and secure with a clamp.

Fit the crankcase ventilation hose to the air intake hose and to the cylinder head cover.

Check engine oil level and top up see point 32.1.

Adjust throttle cable see point 6.8.

Connect ground cable to battery.

Bring the engine up to operating temperature. To do this, warm up the engine while driving until the normal operating temperature of the coolant is reached. Then drive for about 5 km to ensure that the engine oil reaches sufficient temperature.

Check the tightness of the hose connections.

Check ignition timing, see point 4.7.

Check the operation of the engine at idle, see paragraphs. 7.4/8.4.

Set clock.

If necessary, set the security code in the radio, see section "Radio coding".

Engine 124/136 hp

Remove the radiator see point 3.6.

Remove the air quantity meter connector from the air filter housing.

Remove air filter.

Remove the semi-circular cylinder head cover seal from the front.

Remove toothed belt.

Loosen the brace from the intake manifold.

Install in reverse order.

Cylinder Head Bolt Tightening Order

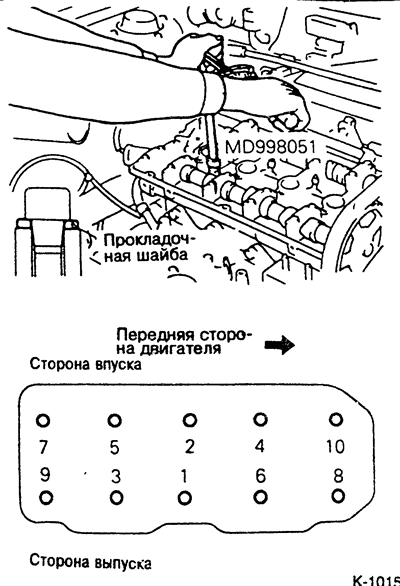

Attention: When tightening the cylinder head bolts, pay attention to the correct position of the shim washers, see illustration.

- 1st pass: with 30 Nm torque wrench.

- 2nd pass: with 60 Nm torque wrench.

- 3rd pass: with 80 Nm torque wrench.

- 4th pass: with 100 Nm torque wrench.

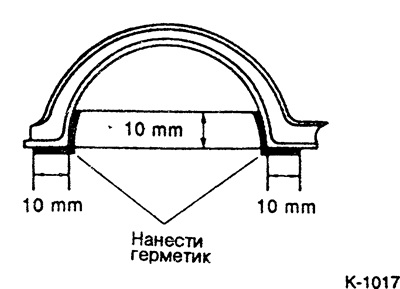

Insert the semi-circular seal as shown in the following figure. First, apply a sealant, such as MITSUBISHI ZM-8660, to the contact surface of the cylinder head and to the seal.

Coat the cylinder head cover gasket as shown in the following figure with a sealant such as MITSUBISHI 3M-8660. Install cylinder head cover and tighten slightly (3 Nm).

Torque:

- Guy: 50 Nm.

- Intake manifold fitting: 30 Nm.

Diesel engine

Disconnect the engine mount see point 1.4.

Remove upper intake manifold see point 1.10.

Loosen the lower part of the intake manifold (nuts, 20 Nm).

Remove spark plugs see point 32.1.

Set the engine to TDC, see point 1.13.

Remove upper toothed belt cover.

Position the camshaft sprocket with toothed belt on the lower toothed belt guard. Before unscrewing the camshaft gear, see point 1.13.

Remove the injection pipes as a set. To do this, loosen the union nuts with 2 wrenches.

Attention: do not disturb the curvature of the injection tubes. After disconnecting the pipes, plug the holes with suitable plugs so that foreign objects and dirt do not get in.

Installation is carried out in the reverse order.

Caution: The mating surfaces of the cylinder head and engine must not be machined.

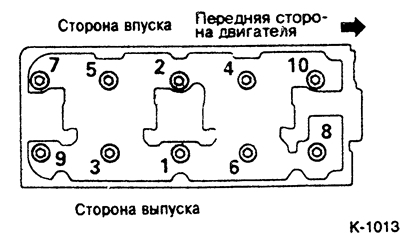

The sequence of an inhaling of bolts of a head of cylinders is resulted on fig. K-1013. Tightening torque for cylinder head bolts

- 1st pass: with torque wrench 30 Nm.

- 2nd pass: with torque wrench 60 Nm.

- 3rd pass: with torque wrench 90 Nm.

- 4th pass: with torque wrench 115 Nm.

Attention: With the camshaft removed, the following additional work must be carried out:

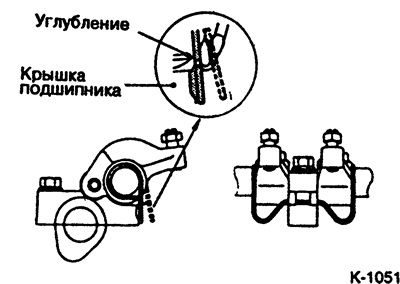

Tighten the camshaft bearing cap bolts evenly in several passes and finally tighten to 20 Nm.

Tighten the fastening of the rocker arm block to the bearing caps and the rocker arm axle support with a force of 30 Nm.

Insert the rocker springs into the groove of the bearing cap as shown in the illustration.

Check valve clearances, adjust if necessary.

Torque:

- Camshaft gear 100 Nm.

- The lower part of the intake manifold 20 Nm.