Since some connections under the vehicle must be disconnected during removal, four stands and one jack are needed to raise the vehicle. Before installation, cover the front fenders to protect them from damage.

Depending on the year of manufacture and on the model, electrical wires, as well as low pressure or coolant hoses, can be routed differently in the engine compartment. Since it is impossible to give a detailed picture of each option, it is recommended to mark the wires with adhesive tape before removal, if necessary. The pictures show a carbureted engine from September 1988.

Removing

- Disconnect the earth cable from the battery.

Attention: This erases the data in the electronic memory, for example, the memory of engine defects or the code of the radio receiver. Disconnect the battery only when the ignition is switched off, as otherwise the control unit of the injection device may fail. Before disconnecting the battery, read the instructions in sections "Radio" And "Removing and installing the battery".

- Remove the engine hood edema, see 20.7.

- Drain the coolant see point 3.3.

- Remove the gearbox see point 12.1.

- Remove the radiator see point 3.6.

- Diesel engine: Drain engine oil, see point 32.1.

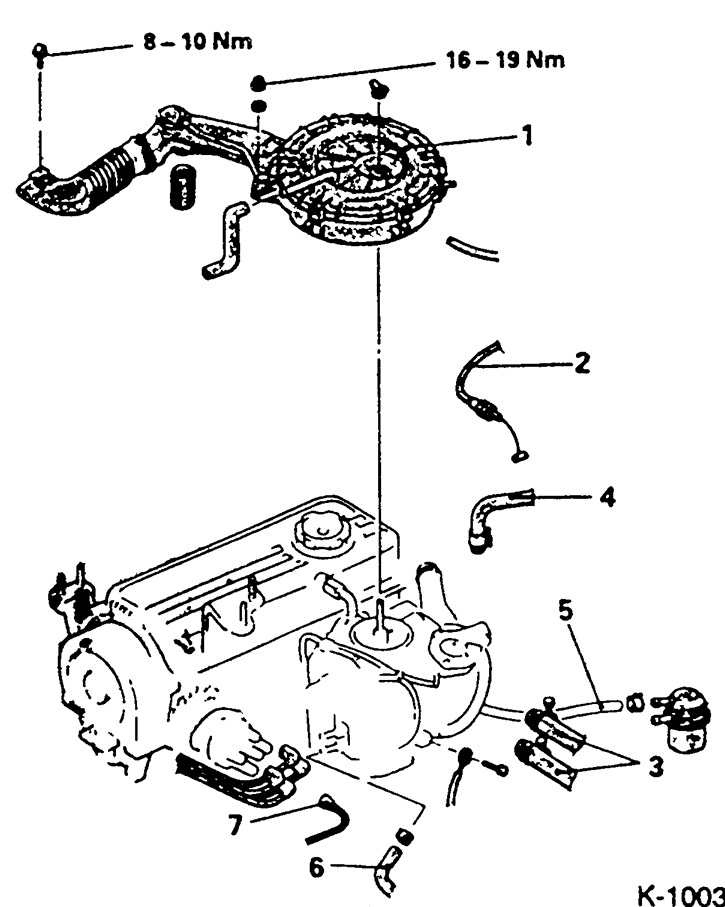

- Unscrew air filter -1-. Disconnect the warm air, low pressure and crankcase ventilation hoses.

- Disconnect throttle cable -2- and move to one side.

- Disconnect the two heater hoses -3- after releasing and fully pushing back the clamps.

- Detach low pressure hose -4- for brake booster from suction pipe.

- Disconnect the supply hose -5- from the fuel pump and the fuel return hose -6- from the carburetor, after releasing the clamps. When removing the hoses, place a rag to collect any spilled fuel. If necessary, close the hoses with suitable plugs. Suitable for this are, for example, screws with the appropriate thread diameter.

- fuel injected engine (MPI): Unscrew the connecting plate of the fuel supply hose from the jpy6bi distributor. Remove the sealing ring, when installing, replace the ring with a new one.

- Vehicles manufactured before August 1990: Pull out the high voltage wire between the ignition distributor and the ignition coil from the middle of the distributor cap.

Attention: To facilitate installation, mark the fuel hoses with adhesive tape.

Caution: The system is pressurized, so the pressure must first be relieved, see point 8.3.

Disconnect all engine wiring:

- Secondary air valve connector -8-.

- Idle speed boost valve connector -9-.

- Connector for cold start ignition timing valve -10-.

- Thermal switch connector -11-.

- Connector for coolant temperature sensor -12-.

- Connector for coolant temperature sensor -13-.

- lambda probe connector (oxygen sensor) -14-.

- Lambda valve connector -15-.

- Intake manifold heating connector -16-

- Connector for throttle position sensor -17-.

- Vehicles produced before August 1990 Distributor connector -18-.

Detach low pressure hose -19- from carburetor.

Disconnect low pressure hose from socket -20-.

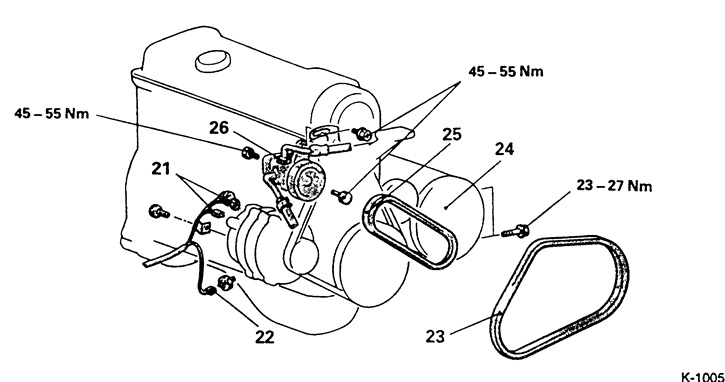

Disconnect from generator thick (B+) -21- and thin (D+) wires. Unscrew the wire fastening from the generator and release the wires from their fastenings at the engine support and at the starter.

Unplug connector -22- for oil pressure switch.

If fitted, remove V-belt -23- for air conditioner. Remove the 3 air conditioning compressor mounting bolts -24- from the bracket and place the compressor aside with the wires connected or hang it on the wire to the body.

Caution: Do not open the refrigerant circuit of the air conditioner. The coolant contains Freon or Frigen and can cause frostbite if it comes into contact with the skin. The engine can be removed without opening the coolant circuit.

Remove V-belt for servo pump -25-, see paragraph 1.21.

Unscrew servo pump -26- and lay aside with hoses connected or hang on wire to body.

lift the car, see par. 29.

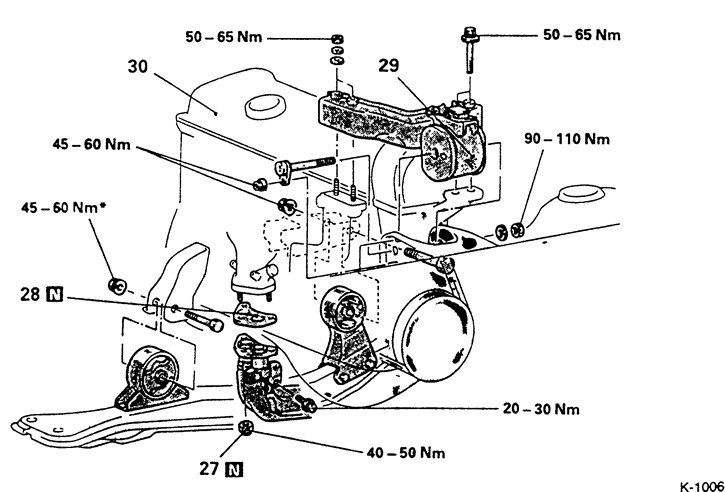

Unscrew front muffler pipe -27-. Lower the muffler and hang it on a wire behind the body, see also point 10.

Remove seal -28-, install new one when installing.

Diesel engine: Loosen the hollow bolts securing the engine oil inlet and outlet pipes to the oil filter connection. Remove seals and replace during installation.

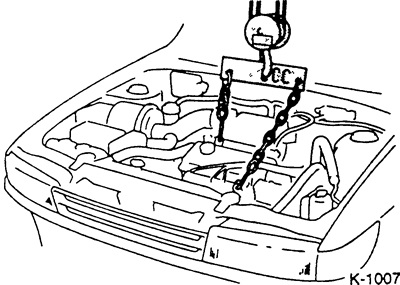

Raise the engine with a crane just enough to relieve the engine mounts.

Unscrew the engine beam -29- (rice K-1006).

Loosen the lower engine mounts.

Check that all wires and hoses are disconnected from the engine.

Raise the engine slowly with a crane.

Attention: Lift the engine carefully so as not to damage the body.

Installation

Check engine mounts, oil and fuel hoses for cavities and cracks and replace if necessary.

Check the clutch disc for sufficient lining thickness and condition. In case of significant wear and high mileage, replace the clutch as a set. If the release bearing makes noise when pressing the clutch pedal, replace the bearing.

Check release bearing for wear and replace if necessary see point 11.2.

Clean and coat with a thin layer of lubricant (e.g. MOS2 grease or MITSUBISHI grease 0101011) clutch release bearing and gear notch of the drive shaft.

Carefully insert the engine into the engine compartment. Be careful not to damage the drive shaft.

Install the engine on supports and bolt, see fig. K-1006.

Attention: First tighten the nut marked 1 by hand Only after the engine is fully lowered, tighten the nut with the prescribed tightening force.

Disconnect the lifting device.

Attach muffler pipe with new gasket to exhaust manifold and secure with new nuts.

Diesel engine: Screw the engine oil supply and return pipes with new gaskets to the oil filter connection fittings with a torque of 45 Nm.

Install the air conditioning compressor.

Install the servo pump.

Install the V-belt see paragraph 1.21.

Connect the connector to the oil pressure switch.

Connect electrical wires to the generator.

lower the car, see par. 29. Put on all low pressure hoses, securing with clamps, see section "Withdrawal".

Connect all electrical wires to the motor, see section "Withdrawal".

Connect the inlet and outlet fuel hoses to the fuel pump and to the carburetor and secure with clamps.

Attention: Do not mix up fuel hoses.

Injection engine: Connect and secure with a new gasket the fuel supply pipe.

Connect the throttle cable to the throttle element and to the heel, see point 6.7.

Connect the low pressure hose from the brake booster to the exhaust manifold and secure with a clamp.

Fit and secure heater hoses with clamps.

Install the radiator see point 3.6. Install the gearbox see point 12.1.

Install engine compartment hood see 20.7.

Diesel engine: Fill with engine oil.

Check the oil level in the engine and gearbox, top up if necessary, see point 32.1.

Check the concentration of antifreeze in the coolant and top up, see point 32.1.

Adjust throttle cable see point 6.8. Connect ground cable to battery.

Warm up the engine to normal coolant operating temperature.

Check hose connections for leaks.

Check ignition timing, see point 4.7.

Check the operation of the engine at idle, see paragraphs. 7.4/8.4.

Set clock.

If necessary, set the radio's security code, see section "Entering the radio code".