Attention: During the measurement of idle speed and CO content, the radiator fan must not turn on. When you turn it on, wait for it to turn off.

Verification conditions

Check the muffler, for which, with the engine running, cover the exhaust pipe with a rag. All joints must be tight.

Caution: Ensure adequate ventilation during this test. Otherwise, there is a danger of poisoning.

Check the play of the rods and carburetor axles, repair or adjust if necessary (workshop work) .

Warm up and turn off the engine. The lower radiator coolant hose should be warm.

Place the transmission in neutral, apply the handbrake. With an automatic transmission, set the shift lever to the position "R". On vehicles with power steering, place the steering wheel in position "directly".

Turn off electrical consumers.

If your vehicle has a cold start cable (Choke buttons), the button must be fully depressed.

The air filter element must be clean, it is best to adjust with a new air filter element.

Connect according to the manufacturer's instructions a speed meter and a CO content meter; the air filter must be fixed. If the vehicle has a distributor with an integrated ignition coil and no tachometer, connect a measuring device, see section "Setting the ignition timing".

FBC carburetor: Press the gas pedal once to unlock fast idle. A short press on the gas pedal will move the lever away from the fast idle cam and thus unlock the fast idle.

Start a warm engine and let it run at idle speed.

Check the ignition timing and the closing angle of the breaker, set if necessary.

Check the tightness of the intake tract. To do this, coat all the seals of the intake device with a brush with gasoline. If at the same time the idle speed is increased for a short time, then the engine can suck in air through leaks. Locate and eliminate leaks.

Attention: Do not inhale fuel vapors - poisonous! Gasoline must not come into contact with hot parts or the ignition system. Flammable!

Examination

Check idle speed, required values see point 7.10.

Raise the idle speed to 2000-3000 rpm for a short time two or three times.

Check CO content, required value see paragraph 7.10.

In case of deviations from the required values, adjust the idle speed and the CO content as follows:

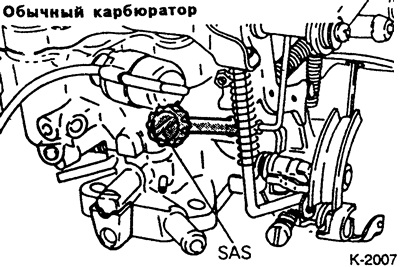

Conventional carburetor / VV carburetor

Adjustment

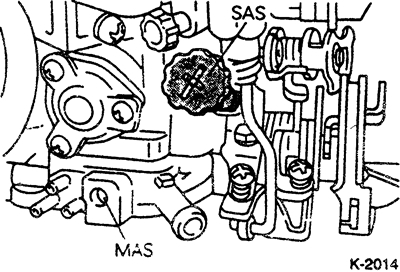

For a conventional carburetor, the idle speed adjustment screw -SAS- is used.

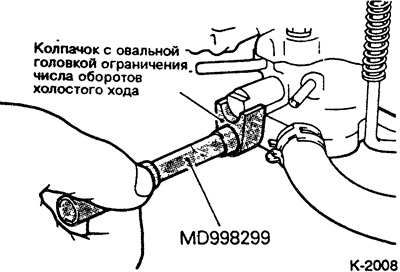

Standard carburetor CO content adjusting screw. A special tool MD-998299 is used to turn the screw.

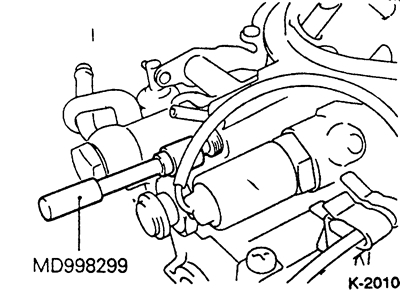

Set screw -SAS- for adjusting the idle speed of the VV carburetor.

VV carburetor CO content adjusting screw. A special tool MD-998299 is used to turn the screw.

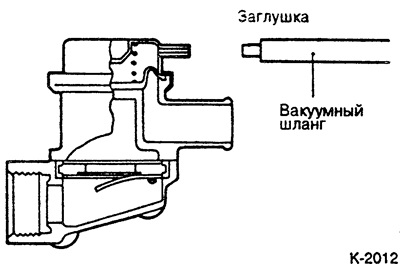

VV carburetor: Disconnect vacuum hose (with white stripes) from the idle speed compensator. Seal the hose opening securely and lay the hose aside.

Adjust the CO content and idle speed by alternately turning the set screws.

Caution: Turn the CO content adjustment screw with great care.

Then increase the speed to 2500 rpm for about 2 minutes.

Let the engine idle for about 3 minutes.

Check idle speed and CO content again and correct if necessary.

Install a new seal.

Disconnect gauges.

FBC carburettor

Typically, idle speed adjustment is not required with electronic air-fuel ratio control.

If, nevertheless, the idle speed adjustment must be made, for example, after repair or overhaul of the carburetor, the adjustment should be made as follows:

Adjustment

Switch off the ignition.

Disconnect the battery ground cable for about 10 seconds and then reconnect.

Remove lambda probe connector. The lambda probe is screwed into the exhaust manifold.

Disconnect the hose from the secondary air control valve and close the hose opening with a plug.

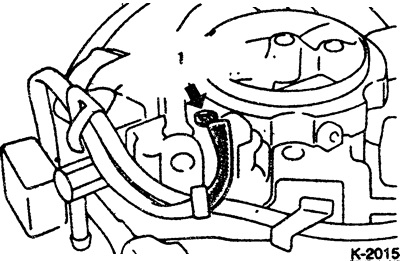

Remove seal from set screw -MAS-, see fig. K-2014, CO content adjustment. To do this, pierce the plastic seal in the center, screw in a suitable screw or self-tapping screw and pull it out together with the seal. If necessary, remove the air filter and then reinstall it.

Start the engine and let it idle for at least 5 minutes.

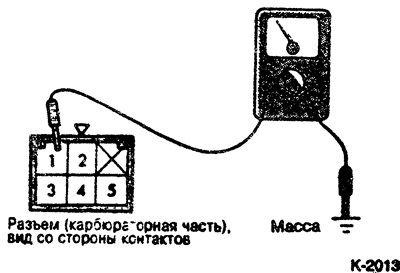

1 - Lambda control solenoid valve

Connect a voltmeter as shown in fig. K-2013, to the lambda valve connector. You don't need to disconnect the connector to do this.

Measure the voltage at idle speed and write under the index "V".

Connect the lambda probe connector.

Raise the speed for about 10 seconds to 2000-3000 rpm.

Take a voltmeter reading and record under the index "X". half value "X" should equal "V" x 0.5 V, otherwise turn the set screw -MAS- until the required value "X" Then repeat the check.

Attention: If this changes the idle speed, set the desired speed with the screw -SAS-.

Leave the engine to run at idle. Press the gas pedal hard (give full throttle) until the engine reaches 3000 rpm, then release the gas again. The voltmeter needle should deviate with an increase in speed, and then again, as soon as the engine switches to idle, return to the reading corresponding to the idle speed.

Connect the vacuum hose to the secondary air control valve after removing the plug

Place a new seal on the set screw -MAS- for the CO adjustment.