If the front tires are noticeably worn, it is recommended to replace them with the rear tires. This results in approximately the same service life of all 4 tires.

Always use a torque wrench when tightening wheel nuts. This ensures that all wheel nuts are evenly tightened.

You should not replace a single tire, but at least dads on the same axle. In this case, tires with less wear must always be installed at the rear. All-wheel drive vehicles must be fitted with tires of the same type and with the same profile pattern.

Attention: Along with the replacement and removal of tubeless tires, for safety reasons, also replace the nipple.

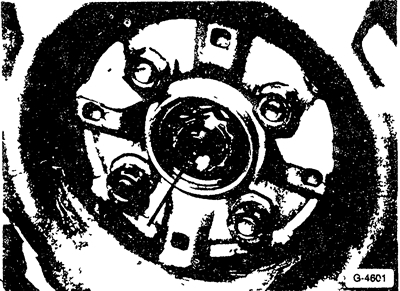

Existing traces of rust on adjacent surfaces of rims should be removed with a wire brush. To protect against corrosion, lightly lubricate the wheel rim mounting hole on the hub at the rear and front with bearing grease each time the wheel is removed.

Remove wheel covers with the blunt end of a wheel wrench (from the on-board tool kit).

Before removing the wheel, mark the position of the rim relative to the hub with chalk or a felt-tip pen, so that after installing the wheel in its original place.

Light metal discs are coated with a clear lacquer to protect against corrosion. When changing wheels, try not to damage the varnish coating, touch up with varnish if necessary.

For light metal rims, use only wheel nuts specifically designed for them.

Attention: If the vehicle is fitted with light metal rims and the spare wheel has a steel rim, put the appropriate wheel nuts for the steel rim in the vehicle tool kit.

Clean contaminated nuts and threads.

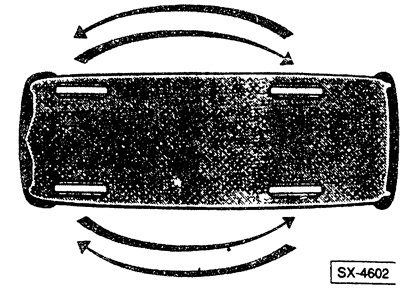

Tighten the nuts crosswise in several passes.

Attention: Due to one-sided or different tightening of the bolts, overstressing can occur in the rim and/or hub.

Wheel nut tightening torques:

Vehicles produced from 9.88 to 3.92:

- 100 Nm for steel and light alloy wheels.

Vehicles from 1.84 to 888:

- steel wheels: 80 Nm;

- light alloy wheels: 100 Nm.