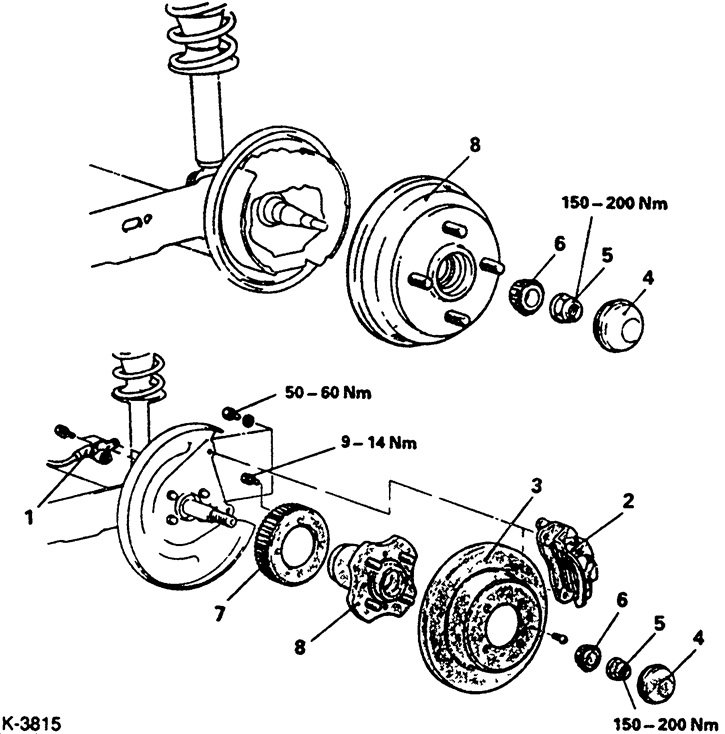

Vehicles from 9.88 to 3.92

1 - Wheel speed sensor (only on vehicles with ABS)

2 - Brake caliper

3 - Brake disc

4 - Hub cap

5 - Self-locking nut

6 - Inner race of the outer wheel bearing

7 - Rotor (only on vehicles with ABS)

8 - Rear wheel hub

Removing

Carefully tap off hub cap -4- with a plastic or rubber mallet.

Apply handbrake and loosen self-locking nut -5- without unscrewing.

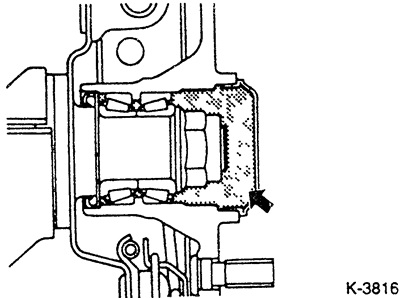

Remove brake caliper see 18.5.

Remove brake disc -3- by unscrewing retaining bolt.

If equipped, unscrew the wheel speed sensor.

9 Loosen nut -5- and remove outer roller bearing -6-. Do not drop the bearing.

9 Remove the brake drum/wheel hub.

On vehicles with ABS: Remove wheel hub and rotor.

Attention: Handle the rotor with care. The rotor teeth must not be scratched or damaged, as this may adversely affect the functioning of the ABS.

Installation

Check the condition of the O-ring on the back of the hub/drum. If traces of grease are visible, replace the ring.

Make sure that there are no chipped places and discoloration of the surface of the bearings and their cages.

Check hub/brake drum for wear and damage.

Insert the hub/brake drum and, if present, the rotor. Possibly drive in the hub/brake drum with a plastic mallet.

Fill with bearing grease and insert outer bearing.

Tighten the new self-locking nut to 150 Nm (on cars produced from 1.84 to 8.88 - 100 Nm) At the same time, clamp the mount between the studs so that the hub does not rotate (do not damage the thread). Great tightening force! Install the wrench horizontally so that the car does not move off the stands when tightening. Tighten the nut in several steps, turning the hub / brake drum in different directions in between to prevent the bearing from jamming.

Note: The old nut can be checked for refitting. To do this, screw the nut onto the wheel stud by 2 and 3 mm. Loosen the nut with a torque wrench. If the loosening force exceeds 5.5 Nm, the nut can be reinstalled.

Check wheel bearing play. Required value: 0.2 mm. If there is too much play, tighten the hub nut to a maximum of 200 Nm (on cars produced from 1.84 to 8.88 - 150 Nm) until the desired backlash value is reached.

If equipped, install the wheel speed sensor.

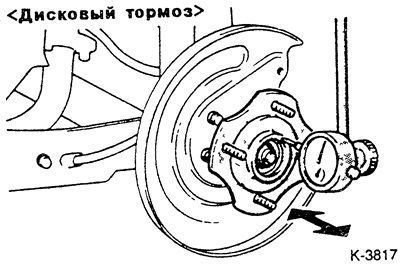

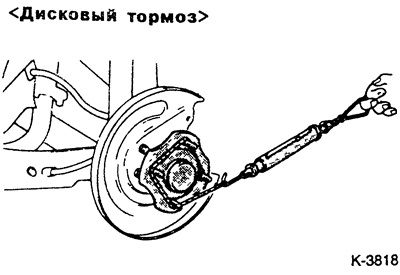

Check bearing torque. To do this, fasten the cord, as shown in the figure, to the studs of the hub / brake drum. Connect the steelyard to the other end of the cord and pull at a 90°angle to the studs until the hub / brake drum begins to rotate. Spring balance readings (steelyard) should not exceed 2.2 kg (on cars produced from 1.84 to 8.88. 1.7 kg, while fixing the steelyard directly on the lower hairpin). If the starting torque is too high, slightly loosen the hub nut. If the required tightening torques (150 Nm - 200 Nm), bearing play and starting torque cannot be achieved at the same time, replace wheel bearings.

Fill the hub cap with bearing grease and press it in as far as it will go.

Install brake disc.

Install the brake caliper see 18.5.