Attention: When the drive shafts are removed, the vehicle must not be moved, because in the absence of axial tension, the running elements of the hub bearings can be damaged. Install drive shafts if necessary to move the vehicle.

Removal of the joint on the gearbox side is different for shafts with and without center bearing.

Designations in the text refer to drawing K-3623.

Removing

Pull off the decorative cap.

If there is one, carefully knock down the hub cap with a plastic hammer.

Straighten and use pliers to pull out the cotter pin -1-.

Loosen fastening nut -2-. At the same time, the assistant press the foot brake pedal so that the hub does not rotate.

Attention: The car must be on the ground. Great turning force. Danger of accident!

Loosen the wheel nuts with the vehicle on the ground.

Mark the position of the wheel rim on the wheel hub with paint. This ensures that the balanced wheel is reinstalled in its original place.

Raise the front of the car see par. 29.

Remove wheel.

Drain the oil from the gearbox see point 32.2.

Loosen hub nut -2- and remove with washer -3-.

Loosen nut -4- and press ball joint -5- downwards, see point 14.6.

Press the joint -7- of the steering tip, see 16.4.

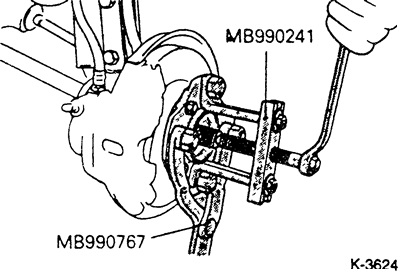

Press the drive shaft out of the wheel hub using a conventional puller. At the service station, the MB-990241 puller is used for this purpose.

Drive shaft without middle bearing

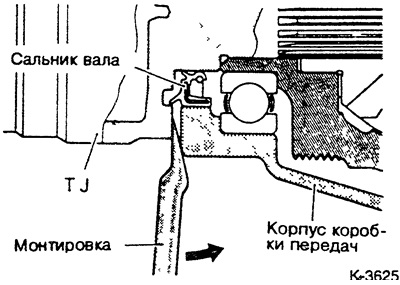

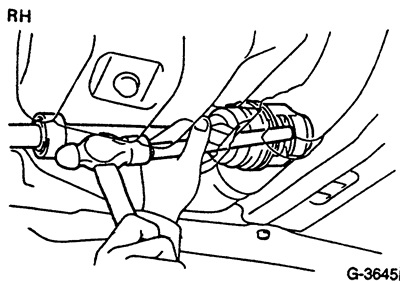

Insert a pry bar between the hinge and the gearbox housing. Reject the mount, thereby depressing the hinge. If necessary, you can press the shaft out of the gearbox grip with a short jerk of the mount. Do not pull on the drive shaft, as this could damage the constant velocity joint! Do not push the mount too far in order not to damage the gland.

Drive shaft with middle bearing (partially on cars produced from 1.84 to 8.88)

Remove the safety ring from the middle bearing.

With light blows of a plastic hammer on the ball joint plate, pull out the drive shaft.

Caution: Pushing with a pry bar can damage the middle bearing.

Check the ease of movement of the middle bearing.

Installation

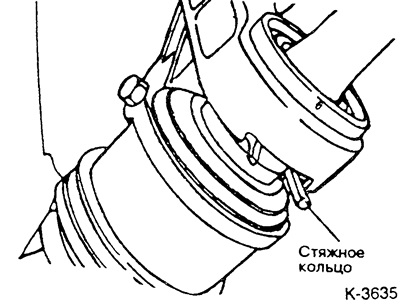

If present, press in center bearing until fully seated in bearing housing. Then secure the bearing with a compression ring.

Check seals for wear before installation.

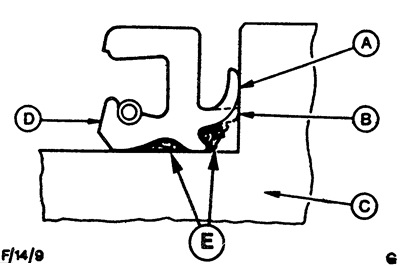

A - a new sealing sponge;

B - worn sealing sponge;

C - wheel hub or drive shaft;

D - stuffing box;

E - lubricant.

Remove worn seal. If necessary, drill a hole in the stuffing box and, having screwed a screw of the appropriate diameter into the hole, pull out the stuffing box, holding the screw with pliers.

Attention: If the oil seal is defective or worn, check the integrity of the rollers and bearing cages, replace if necessary.

Coat the new oil seal with grease as shown in the illustration and press the oil seal evenly using a tube of the correct diameter.

Clean and lightly lubricate the splines and threads of the drive shaft.

|  |

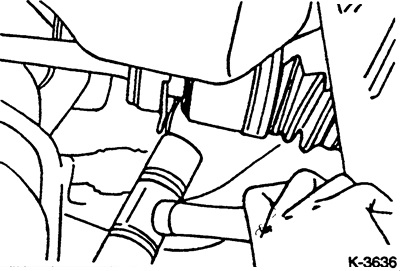

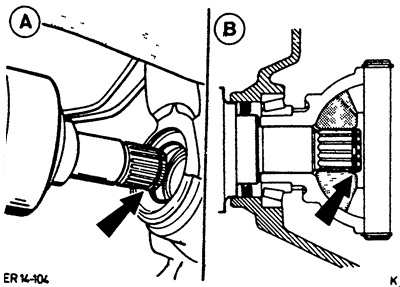

Insert the drive shaft with a new circlip -arrow A- into the spline of the bevel gear and press it in with a hammer and a brass rod until it snaps into place -arrow B-. By lightly pulling and pressing, check the perfect fit of the shaft. It should be impossible to pull it out by hand.

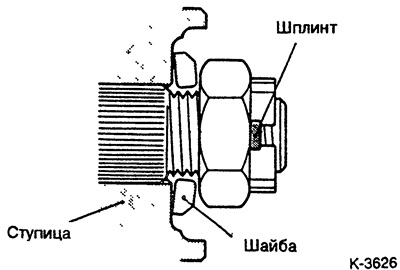

Apply the washer as shown in the figure and screw on, without tightening, the fastening nut.

Fasten the ball joint with a tightening torque of 70 Nm.

Tighten the steering knuckle joint with a torque of 30 Nm and install a new cotter pin.

Install the wheel, taking into account the marking made of its position relative to the hub. Lower vehicle and tighten cross wheel nuts, tightening torques see 19.4.

Tighten the hub nut to at least 200 Nm. If the cotter pin holes in the nut and the shaft do not match, tighten the nut again (up to 260 Nm) until the holes line up. The pin must be new.

Pour oil into the gearbox see point 32.2.

If removed, carefully install the hub cap.

If possible, urgently check the alignment of the front wheels of the car.