Examination

Inspect cuffs, replace defective cuffs immediately. To replace the protective cuffs, the drive shaft must be removed and disassembled. If dirt is found in the hinge, wash the hinge with gasoline and lubricate with a new special grease (contained in cuff repair kit).

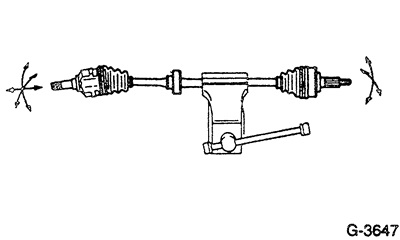

Fix the removed drive shaft in a vise and check the mobility of the hinges.

Check the integrity and degree of wear of the wedge grooves.

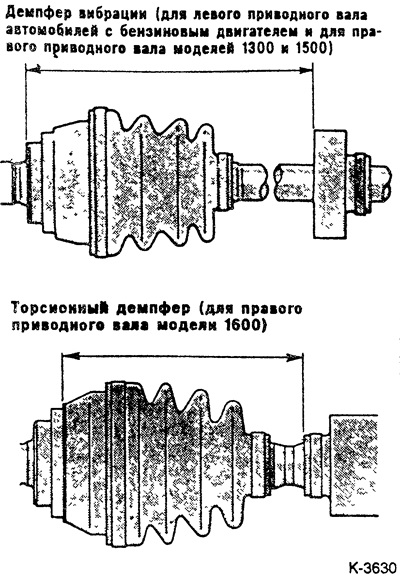

Check the reliability of fastening, make sure that there are no cracks or damage to the vibration dampers and torsion dampers.

If defects are found, disassemble the drive shaft.

Disassembly

Before removing, mark the edges of the joint collar on the shaft with a felt-tip pen, which will facilitate subsequent assembly.

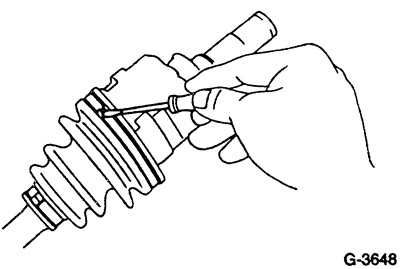

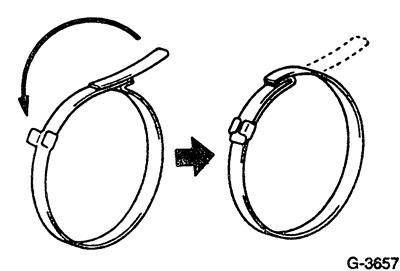

Use a screwdriver to pry off the cuff tapes on the inner hinge and remove.

Slide the cuffs along the shaft.

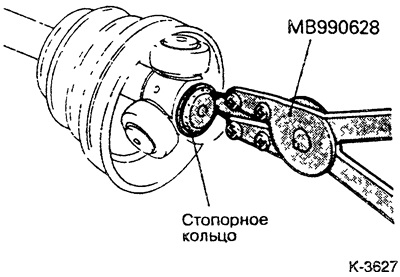

Spread the retaining ring with special pliers (e.g. HAZET) and remove it from the hinge pin.

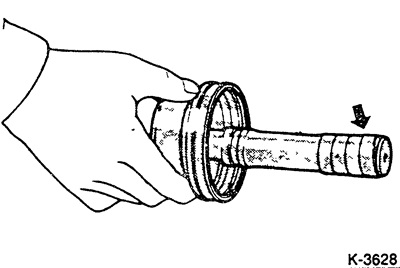

Remove the cross and clean.

Attention: Do not disassemble the cross joint.

Apply adhesive tape to the wedge grooves to prevent damage to the cuffs when tightening.

Mark the position of the vibration damper or torsion damper with a felt pen.

Remove the joint, vibration damper, torsion damper and joint collars from the shaft.

Caution: The outer hinge must not be disassembled.

Thoroughly wipe the hinge cavities, internal parts, flanges, cap and cuffs. Remove existing old grease with solvent and compressed air.

Check the wear of the working surfaces and the hinge mating elements, replace the hinge if necessary.

Assembly

Replace porous and defective cuffs. Be sure to install new clamping strips and retaining rings.

Lightly lubricate the surface of the shaft so that the cuff slides better. In addition, wrap the shaft splines with adhesive tape so that the cuffs are not damaged when put on.

Put on the cuff of the outer hinge with a clamp, do not fasten the clamp. Do not confuse the cuffs of the hinges: the cuff and collar of the outer hinge are smaller than those of the inner hinge.

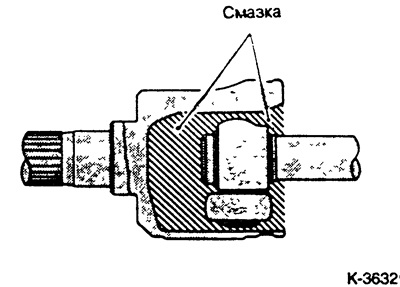

Fill the inside of the hinge and collar with the prescribed amount of grease. Grease is available in the cuff repair kit.

Engine - Lubrication Quantity:

- 1.3/1.5 l - 75 - 95 g

- 1.6 l (16 cells) / 1.8 l diesel - 90 g

- 1.8 l (16 cells) – 100-120 g

Attention: Fill the joint with half of the grease, and the cuff with the other half.

Fasten clamps.

Attention: The joint must not be deflected while doing this.

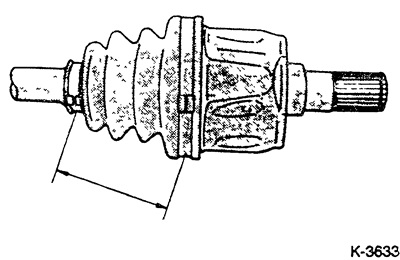

Install the vibration damper and / or torsion damper in the marked place and secure with a clamp. When installing a new drive shaft, the following distances apply:

Engine - Distance:

- 1.3/ 1.5 l - 434-440 mm

- 1.6 l (16 valves.) / 1.8 l diesel left - 140-145 mm

- 1.6 l (16 valves.) / 1.8 l diesel right - 221-227 mm

- 1.8 l (16 valves.) torsion damper - 195-201 mm

Caution: The rubber part of the vibration damper and torsion damper must not be exposed to grease, otherwise it must be wiped off immediately.

Apply special grease to the cross joint (from repair kit) .

Attention: Do not use other greases, do not mix old and new greases, do not mix greases of different types.

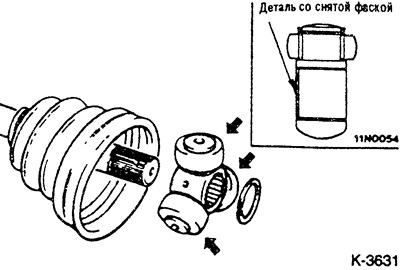

Mount the joint cross on the shaft with the chamfered parts first.

Insert a new circlip into the shaft groove.

Fill the inside of the hinge and collar with the prescribed amount of grease. Grease is available in the cuff repair kit.

Engine - Lubrication Quantity

- 1.3/1.5 l - 115-135g

- 1.6 l (16 cells) / 1.8 l diesel - 110 g

- 1.8 l (16 cells) — 110-130 g

Attention: Fill the joint with half of the grease, and the cuff with the other half.

Push on and align the clamps, observing the correct distances:

Engine - Distance

- 1.3/1.5 l left - 80±3 mm

- 1.3/1.5 l right - 85±3 mm

- 1.6 l (16 valves.) / 1.8 l diesel left - 80±3 mm

- 1.6 l (16 valves.) / 1.8 l diesel right 1.8 l - 85±3 mm

- (16 valves.) - 85±3 mm

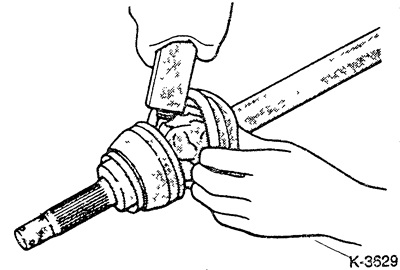

The cuffs must be securely seated in the grooves of the shaft. Bend the cuff bands with a screwdriver and, as shown in the figure, secure by bending the spouts.

In the installed position, the cuffs should not be stretched or flattened. Pull on and fasten the cuff strips.

Install drive shaft.