Attention: Separate parts of the brake mechanisms of the left and right wheels are different; therefore they are not interchangeable. When removing parts, lay them out in such a way as to install them in their original places.

Removing

Carefully knock off the grease cap -1- with a plastic or rubber mallet.

Tighten the handbrake, loosen the self-locking nut -2- without unscrewing it.

Mark the position of the rim on the wheel hub with paint. This ensures that the balanced wheel is reinstalled in its original place.

Raise the back of the car see par. 29.

Remove wheel.

Release the handbrake.

Loosen nut -2- and remove brake drum -4- with outer wheel bearing -3-. Make sure that the bearing does not fall out.

Attention: after removing the brake pads, do not press the brake pedal, as the piston will come out of the brake cylinder.

Before removing the return springs, it is recommended to note their mounting position. This will make subsequent installation easier.

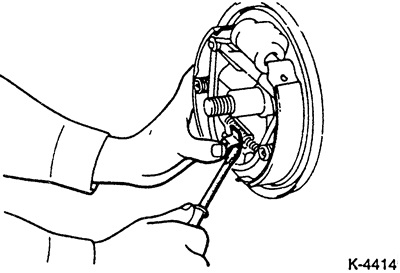

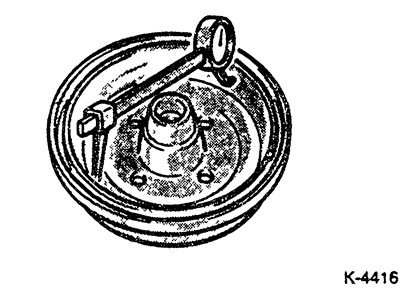

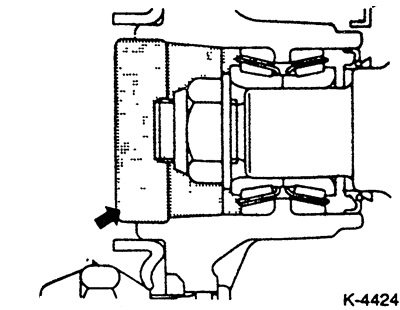

Vehicles from 1.84 to 5.90: Depress the clamping spring with a large screwdriver as shown in the illustration.

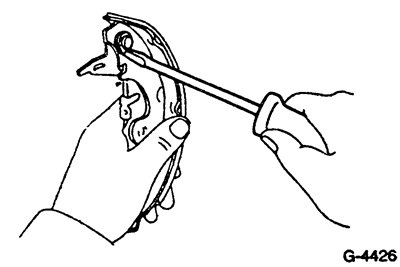

Disconnect the return springs with a suitable screwdriver or pliers.

Attention: Spring -11- (brake type 2) is under great tension. Danger of accident!

Remove the setting lever and setting piece.

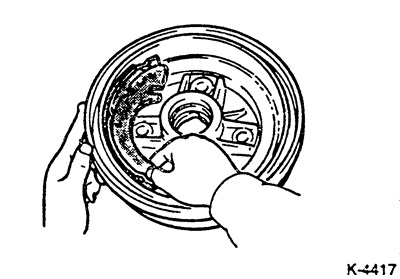

Firmly compress the spring cup with pliers and turn 90°. While compressing, hold the fixing pin on the rear side of the brake shield.

Disconnect the lower spring from the front brake shoe and remove the front brake shoe.

Swing down the rear brake shoe and disconnect the handbrake cable from the handbrake lever.

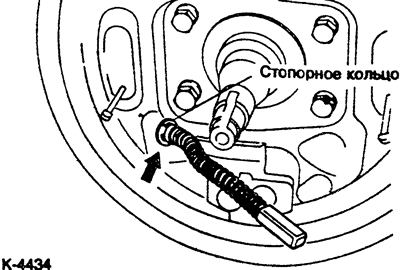

If it is necessary to remove the handbrake cable, disconnect it from the brake shield. To do this, compress the spring with pliers and pull out the circlip with a screwdriver.

Remove boot from working brake cylinder -5-.

Caution: The cylinder piston must not protrude while doing this. Check if it is dry behind the boot cuff. If moisture is present, replace the wheel brake cylinder.

Put the dust boot on the working brake cylinder.

Installation

It is imperative to replace all 4 brake pads at the same time, even if only one of the brake pads has reached the wear limit. Install only one type of brake pads. Clean the brake drum and brake caliper with a vacuum cleaner or alcohol. If the brake cylinder is wet with brake fluid, replace the cylinder. Ensure that the threads of the setting device move freely and lightly lubricate with MoS grease2. Boring brake drums with scratches and grooves, while processing both drums at once. Observe the upper permissible drum diameter (wear limit), see 18.17.

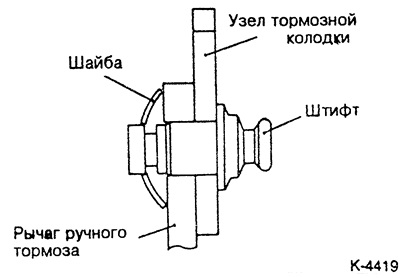

Move the handbrake lever from the old to the new brake pad.

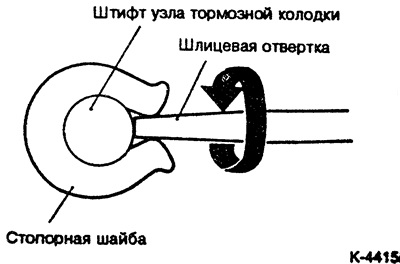

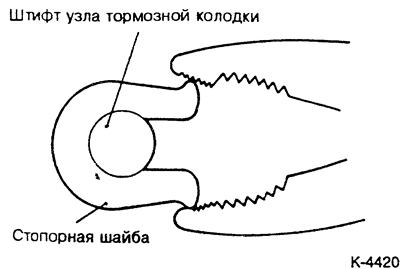

To do this, spread out the lock washer and remove the thrust washer.

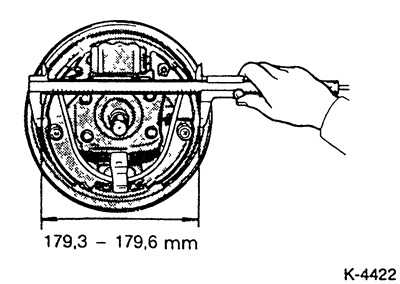

Measure the diameter of the brake drum in at least 2 places. When the wear limit is reached or if wear is very uneven, replace the left and right brake drums and brake pads.

Check the compatibility of the shape of the brake drum and brake shoes. To do this, cover the inner surface of the brake drum with a layer of chalk and rub it with a brake shoe. If the contact surface is very uneven, replace the brake pad.

Clean the contact points between the brake pads and backboard, brake pads and locking pins, and the back of the piston, and before installing the brake pads, coat with a thin layer of high temperature grease, preferably high temperature copper paste.

Lubricate the thread and contact points of the setting element also lightly. Attention: Do not allow grease to get on the brake pads and brake linings.

Position the handbrake lever and install the thrust washer as shown in the illustration.

Install the lock washer using pliers.

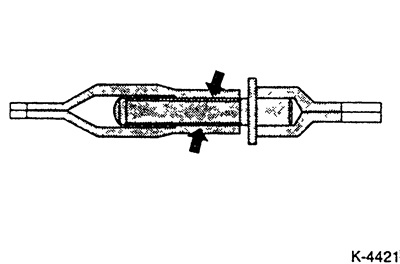

Lubricate the threaded part and the inner surface of the coupling with high-temperature paste. SAE J310 NLGI Nr.1 brake paste may be used.

If removed, connect the handbrake cable to the brake shield guide. To do this, tighten the spring with pliers and insert the retaining ring.

Connect the handbrake cable to the handbrake lever.

Install the brake shoe and secure it with locking pins, cups and springs. At the same time, hold the locking pins at the back and at the same time press the spring cup with pliers and fix it by turning it by 90°.

Insert the return springs into the brake shoes using brake spring pliers.

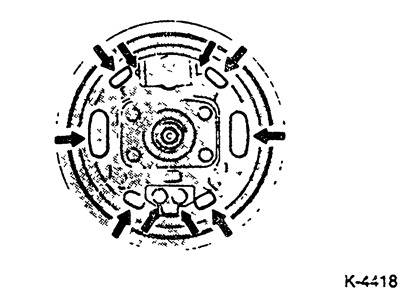

Attention: Pay attention to the correct position of the return springs, see illustrations.

Check the functionality of the automatic installer. To do this, move the handbrake lever on the rear brake shoe forward and backward. In this case, the set screw must turn. If the set screw does not turn, it is usually due to improper installation of the brake pads, repeat the installation.

Use a screwdriver to turn the setting roller to the position of the shortest adjustable length.

Turn the adjusting screw to adjust the outer diameter of the brake pads to the required value.

Attention: The handbrake lever must be released. When the lever is pulled by the handbrake cable, automatic brake pad setting does not function.

Put on the brake drum.

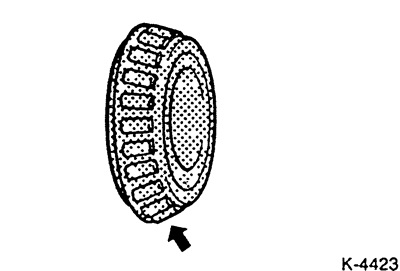

Apply bearing grease to the inner race of the outer bearing.

Insert the hub bearing and screw on, without tightening, a new hub nut.

Put the wheels in accordance with the marking, screw the wheel nuts. Lower the vehicle and tighten the nuts crosswise. Torque see 19.4.

Tighten the hub nut with the vehicle on the ground.

Fill the grease cap with bearing grease and install it.

By repeatedly pressing the brake pedal, make the basic setting of the clearance in the rear wheel brakes. At the same time, clicks in the brakes are heard before reaching the gap setting.

Adjust handbrake.

On the road, in the absence of vehicles, make trial braking at medium speed.