Removing

Mark the position of the rim on the wheel hub with paint. This ensures that the balanced wheel is reinstalled in its original place.

Raise the front of the car see par. 29.

Remove wheel.

Attention: Swapping pads from the outside to the inside and vice versa, as well as from the right to the left wheel and vice versa is not allowed. Swapping pads can cause uneven braking. Be sure to replace all pads on the same axle at the same time. If it is necessary to reinstall the pads, mark the pads before removing them.

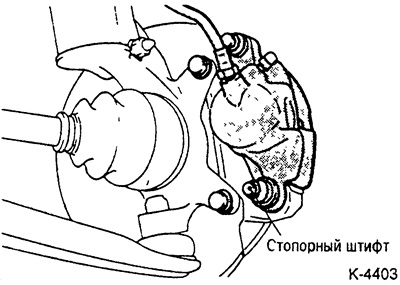

Unscrew locking pin, tilt brake caliper up and secure with wire to vehicle. Make sure that the brake hose is not stretched.

Attention: Do not remove the brake hose, otherwise you will have to remove air from the brake system. The locking pin is coated with a special grease. Never remove grease. Make sure no dirt gets in.

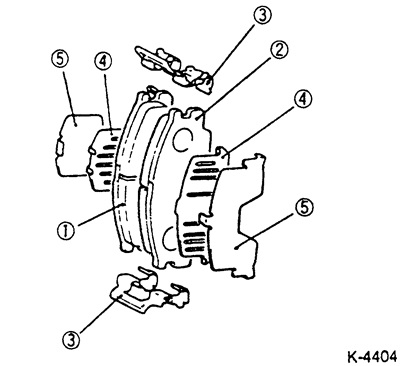

Pull out the brake pads with spacer springs, spacers and anti-squeak pads.

1 - Brake pad with wear indicator

2 - Brake shoe

3 - Bracket

4 - Inner washer

5 - Outer washer

Attention: Brake pads and parts (staples and gaskets) vary depending on the model and year of manufacture of the vehicle. The picture shows a repair kit for vehicles from 9.90 to 3.92. If the vehicle has brake pad parts that differ from those shown in the figure, be sure to note their installation position. In addition, it is recommended that you first remove the brake pads on only one wheel and only after they are properly installed, replace the pads on the other wheel.

Installation

Attention: When the brake pads are removed, do not press the brake pedal, otherwise the piston will be squeezed out of the housing.

Clean the guide surfaces and pad seats with a soft metal brush or clean with a cloth soaked in alcohol. Do not use any solvents containing mineral oils or sharp-edged tools.

Before installing the pads, check with your fingers that there are no grooves on the brake disc. If there are grooves or scratches, replace the brake disc.

Measure the thickness of the brake disc, see point 18.3.

Make sure that there are no ruptures and cracks on the anther and cuffs in the caliper. Replace a damaged boot immediately, as penetrating dirt quickly leads to depressurization of the brake caliper. To do this, the caliper must be removed and disassembled (workshop work).

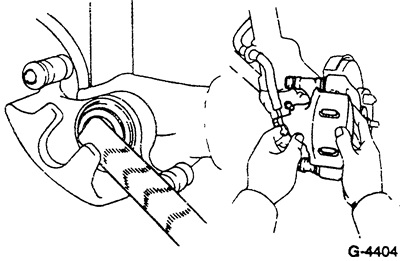

Drown the piston with a strong wooden rod (hammer handle) , while paying special attention to ensure that the piston is not warped and the dust boot is not damaged.

Attention: When the piston is depressed, the brake fluid is squeezed out of the brake cylinders into the reservoir. Monitor the fluid level in the reservoir, if necessary, suck out the brake fluid.

When suctioning, use a plastic bottle, which should only be used for brake fluid. Do not use drink bottles! Brake fluid is poisonous and must never be sucked out by mouth through a hose. Apply suction. After replacing the pads, the level of brake fluid in the reservoir should not exceed the MAX mark, as the fluid expands when heated. Leaking brake fluid flows onto the brake master cylinder, destroying paint and causing corrosion.

Attention: If the pads are heavily worn, check the ease of movement of the piston. To do this, insert a wooden block into the brake caliper, and the assistant slowly press the brake pedal. A wooden block is installed to prevent the piston from completely retracting. The brake piston should move in and out easily, another caliper can be installed to check. Make sure that the piston does not come out completely. If, by negligence, the piston is completely squeezed out, after installing the piston, air must be bled from the brake system, see clause 18.11.

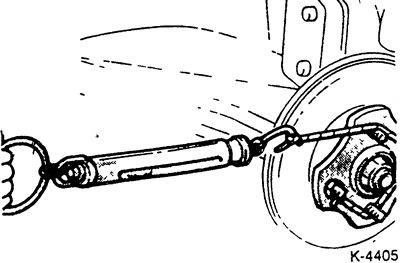

Measure the starting torque of the wheel hub as shown in the illustration and record the measured value.

Attach the brackets to the brake caliper bracket.

To prevent squeaking of disc brakes, coat the reverse sides of the brake pads, as well as the anti-squeal linings, with a thin layer of lubricant (e.g. Plastilube, Tunap VC 582/S, ChevronJSRJ/2, Liqui Moly LM-36 or LM-508-ASC, brake paste SAE J310 NLGI Nr. 1). Lubricant must never get on the working surface of the brake pad and on the brake disc. In case of contact, wipe off the grease immediately and clean the surface with alcohol. Apply the paste in such a thin layer that in the installed state, when the brake pad is pressed during braking, it does not protrude beyond the edge.

Note: Paste is available in some repair kits.

Slide both brake pads with new anti-squeak pads into the retaining springs in the caliper bracket.

Tilt the piston housing down and insert and tighten the locking pin with a force of 30 Nm.

Start the engine, press and hold the brake pedal for about 5 seconds. In this case, the brake pads will take up their working position. Stop the engine and rotate the wheel hub 10 revolutions forward. After that, measure the moment of starting off the wheel hub, see fig. K-4405. Compare the measured value with the starting torque measured with the old brake pads. If the difference exceeds the required value, it is necessary to disassemble and repair the brake caliper (workshop work).

Required value for conventional brake disc:

- 35 N (3.5 kg) or less.

Required value with blown brake disc:

- 70 N (7.0 kg) or less.

Put the wheels in accordance with the marking, screw the wheel nuts. Lower the vehicle and tighten the nuts crosswise. Torque see 19.4.

Caution: Press the brake pedal firmly several times until strong resistance appears.

Check the fluid level in the reservoir and, if necessary, top up to the MAX mark.

Carefully break in new brake pads, for which several times with a small effort on the brake pedal, brake the car from a speed of 80 km / h to 40 km / h. Allow brakes to cool between braking.

Attention: For the first 200 km, do not allow full braking.