Removing

Mark the position of the rim on the wheel hub with paint. This ensures that the balanced wheel is reinstalled in its original place.

Raise the front of the car see par. 29.

Remove wheel.

For rear disc brakes only: Fully release the handbrake and disconnect the handbrake cable from the brake caliper.

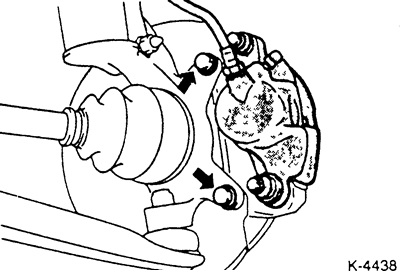

Disconnect the brake caliper and, together with the installed brake pads, hang with a wire on the body or on the rack.

Attention: Suspend the brake caliper, avoiding tension or twisting of the brake hose.

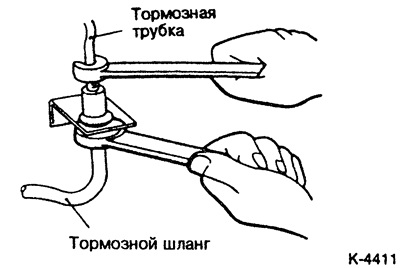

If it is necessary to completely remove the caliper, disconnect the brake hose. To do this, unscrew the union nut while holding the hexagon wrench on the brake hose at the same time. Loosen the clamp of the brake hose holder and remove the brake hose from the holder.

Warning: Brake fluid will leak out. Collect brake fluid in a bottle designed exclusively for brake fluid. After installation from brake system it is necessary to remove air.

Installation

To ensure uniform braking on both sides, both brake discs must have the same working surface in terms of grinding and roughness height. Therefore, you should replace the brake discs on the same axle at the same time.

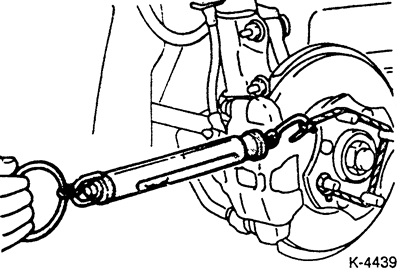

Check bearing torque. To do this, fasten the cord, as shown in Figure K-4439, to the hub studs. Connect the steelyard to the other end of the cord and pull at an angle of 90°to the studs until the hub begins to rotate. Spring balance indication (steelyard) write down.

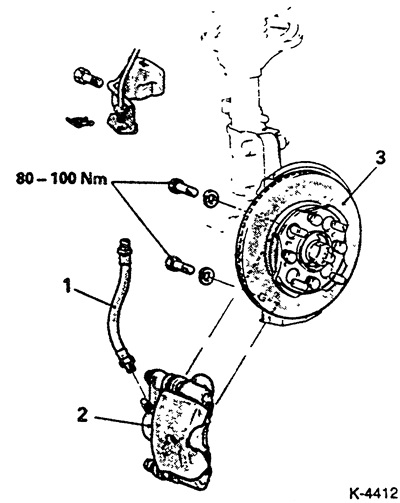

Attach the brake bracket with 2 bolts to the steering knuckle. The tightening torque of the front caliper mounting bolts is 100 Nm. Fasten the rear wheel caliper with a force of 60 Nm.

If the brake hose was removed, insert the brake hose into the holder and secure with a clip. Screw on the union nut of the brake pipe. Do not twist the hose when installing. Tighten the cap nut to approx. 15 Nm.

If the brake system has opened, bleed the air from the brake system, see clause 18.11.

Loosen wheel nuts.

For rear disc brakes only: Connect handbrake cable.

Measure the starting torque with the brake pads installed as follows:

Start the engine and let it idle.

Attention: The transmission must be in neutral position.

Press and hold down the brake pedal for approximately 5 seconds.

Turn off the engine.

Rotate the wheel hub 10 turns forward.

Measure the starting moment of the wheel hub, as shown in the figure. Compare the measured value with the starting torque measured with the brake pads removed. If the difference exceeds the required value, it is necessary to disassemble and repair the brake caliper (workshop work).

Required value:

- with conventional brake disc 35 N (3.5 kg).

- with blown brake disc 70 N (7.0 kg).

If the required value is exceeded, the brake caliper should be disassembled, the sliding elements cleaned and the wear of the piston cuff checked (workshop work).

Put the wheels in accordance with the marking, screw the wheel nuts. Lower the vehicle and tighten the nuts crosswise. Torque see 19.4.

Caution: Press the brake pedal firmly several times until strong resistance appears.

Check the fluid level in the reservoir and, if necessary, top up to the MAX mark.

Rear wheel disc brakes: Adjust the handbrake, see 18.15.