Mark the position of the rim on the wheel hub with paint. This ensures that the balanced wheel is reinstalled in its original place.

Loosen the wheel nuts on the vehicle on the ground.

Raise the front of the car see par. 29.

Remove wheel.

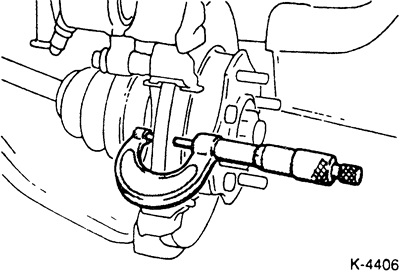

Measure the brake disc thickness. In workshops, a special caliper or caliper with a micrometer is used for this, since when the brake disc wears, a protrusion forms on its edge. The thickness of the brake disc can also be measured with a conventional caliper, but pads of known thickness should be placed on both sides of the disc and the thickness of the two pads should be subtracted from the measured value.

Attention: Measure at least 4 points on the brake disc.

If the wear limit is reached, replace the brake disc. Wear limit values, see 18.17.

In case of significant scratches and grooves with a depth of more than 0.5 mm, replace the disc.

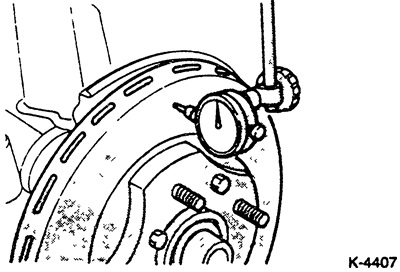

If equipped with a dial indicator, measure the lateral runout of the brake disc. Install the dial indicator at a distance of 5 mm from the edge. Required value: maximum 0.15 mm. Excessive lateral runout may be caused by a broken front wheel bearing, visit a dealer to check.

Remove wheel nuts.

Put the wheels in accordance with the marking, screw the wheel nuts. Lower the vehicle and tighten the nuts crosswise. Torque see 19.4.