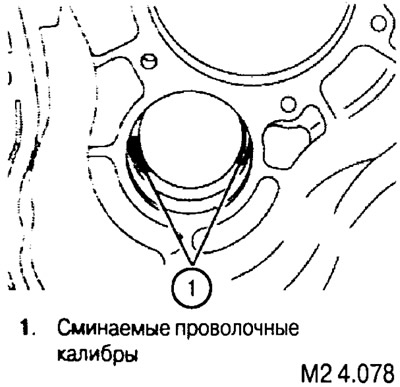

For this crumpled pieces of wire (further - calibers) should be installed in the bearing seats as shown in Figure M2 4.078.

After that, you need to install the intermediate shaft with bearings and tighten the screws securing the front cover of the transfer case to a torque of 35±6 Nm.

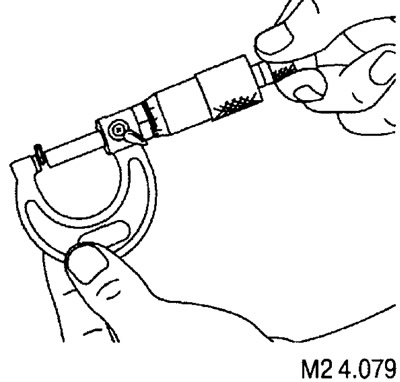

After crimping the fastening screws, remove the intermediate shaft and measure the thickness of the crumpled calibers.

Note: if the gauges are not crumpled, then larger diameter gauges should be used (diameter: 1.6mm, length: about 10mm) and repeat measurements.

According to the measurement results, adjusting washers should be selected. To do this, subtract from the value of the thickness of the crumpled gauge from 0 mm to 0.15 mm, and select a washer with the thickness closest to the calculated value. The normal clearance after correct selection of the shim should be between 0 mm and 0.15 mm.