Each instance of this product is assigned a 30-digit alphanumeric identification code, which corresponds to information about the individual characteristics of the nozzle. When installing a new injector, the code printed on its body is entered into the ECM using the control and diagnostic equipment. Such individualization allows you to customize the injector control with the most successful set of ECM output parameters.

Operating principle

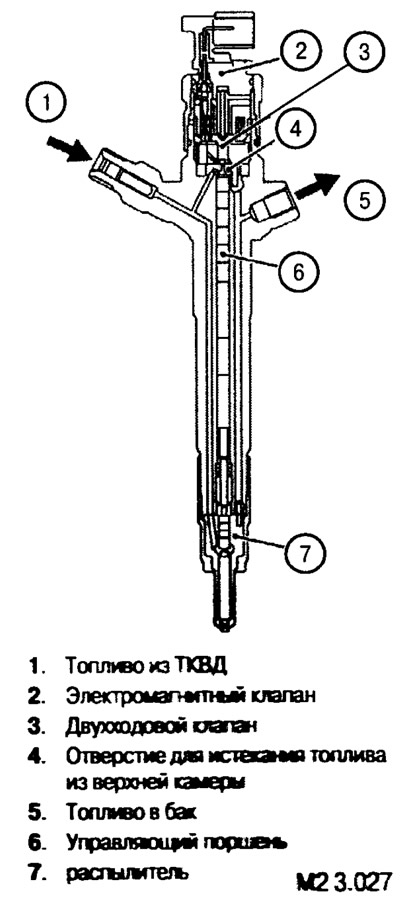

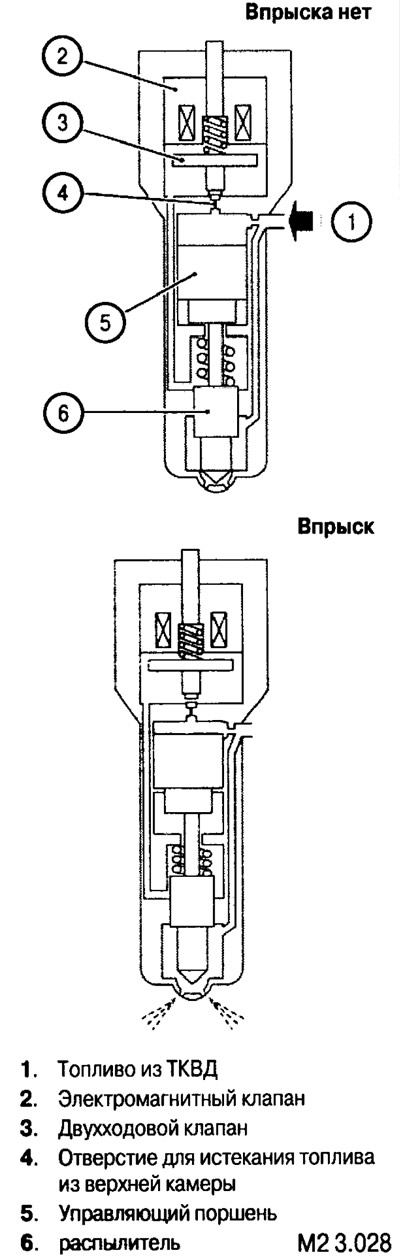

High pressure fuel is supplied to the injector. Significant mechanical force is required to open the sprayer valve.

Fuel pressure is used as the energy source to open the sprayer valve.

The nozzle has two cavities into which fuel is supplied under pressure. In these cavities, the fuel presses on the special end surfaces of the control piston. The forces developed by the fuel from both sides are balanced. When a control signal is applied to the winding, the electromagnet opens a special hole through which fuel flows from the upper control chamber into the drain line. The balance of forces acting on the control piston is disturbed, and the piston, moving up, opens the spray valve. After removing the signal from the electromagnet in the chambers, it is restored, and the piston, under the action of a return spring, closes the spray valve.

|  |