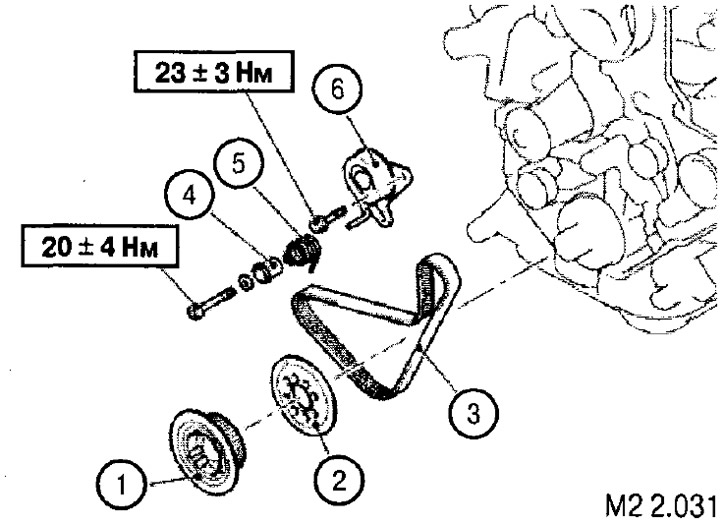

1. Crankshaft pulley; 2. flange; 3. Belt «IN»; 4. Tensioner sleeve; 5. Tension spring; 6. Tensioner assembly

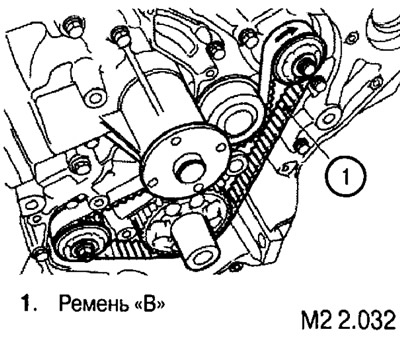

Removing the belt «IN»

Note: if you plan to continue using this belt, before removing it, put an arrow on its non-working surface with chalk indicating the direction of rotation of the pulleys.

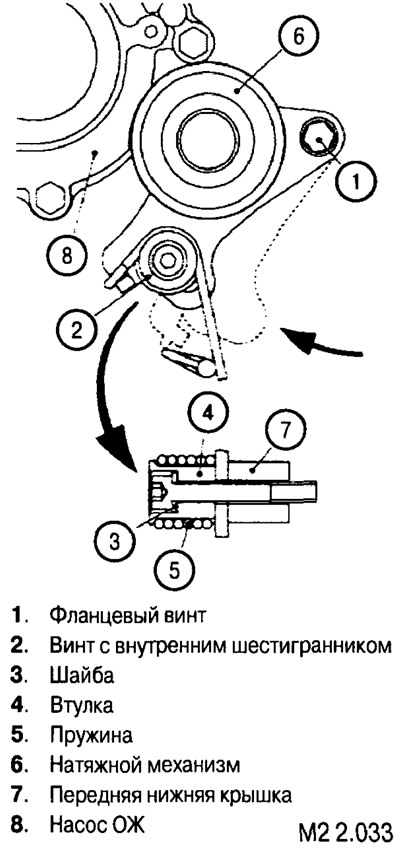

Loosen the fixing screws (flanged and with hexagon socket) tensioning mechanism of the belt, move it towards the coolant pump and tighten the screws to fix the mechanism.

Remove the belt from the pulleys.

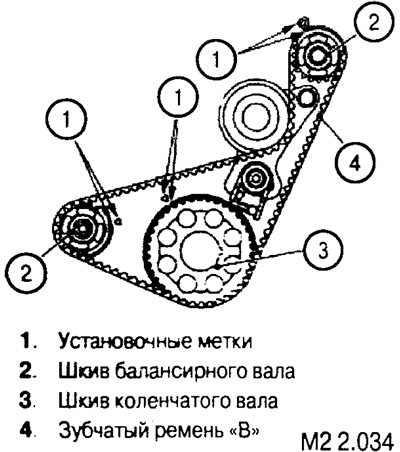

Installing the belt «IN»

Check that the piston of the first cylinder is in the TDC position. Align the pulley marks and install the belt on the pulleys according to the direction of rotation (if a previously removed belt is used).

Loosen the screws securing the tensioner (flange screw - 1 turn, and hex socket screw - 1-2 turns). This will move the tensioner and tension the belt.

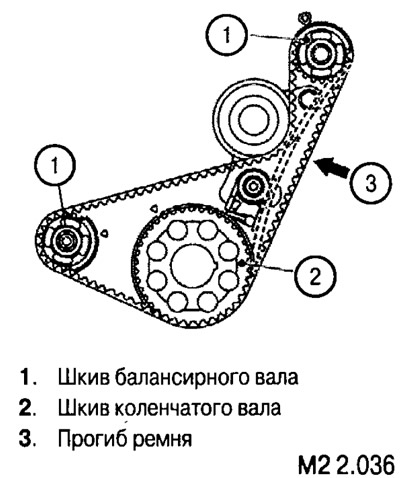

Check that the deflection of the belt at the point indicated in Figure M2 2.036 (pressing on the belt with the index finger), is within 4-5 mm.

Then tighten the hex screw first and then the flange screw.

Tightening torques:

- flange screw - 23±3 Nm;

- hexagon socket screw -20±4 Nm.