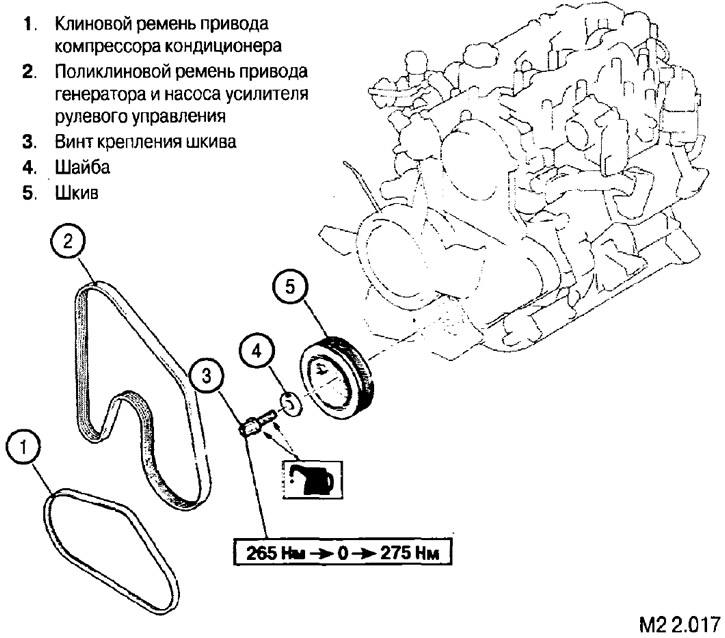

Note: after assembly, the tension of the belts must be checked (1) And (2) and adjust the belt tension if necessary (2). Due to the presence of an automatic tensioner, adjusting the belt tension (1) not required.

These operations are described in the section «Maintenance».

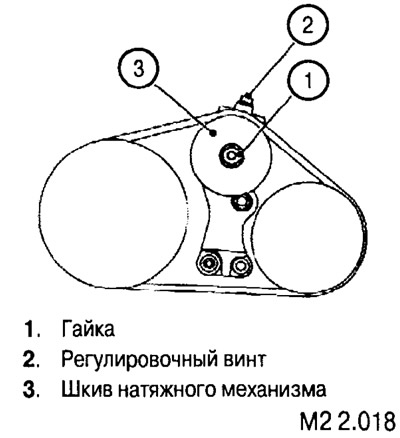

Removing the A/C Compressor Drive Belt

Note: if you plan to continue using this belt, before removing it, put an arrow on its non-working surface with chalk indicating the direction of rotation of the pulleys.

Loosen the pulley nut. By turning the adjusting screw of the tensioner (counterclock-wise), loosen and remove the belt from the pulleys.

Removing the alternator drive belt and power steering pump

Note: if you plan to continue using this belt, before removing it, put an arrow on its non-working surface with chalk indicating the direction of rotation of the pulleys.

Using a spanner wrench, turn the auto tensioner and insert a hex key into its hole (to fix the mechanism). Remove the belt from the pulleys.

The belt is installed in the reverse order.

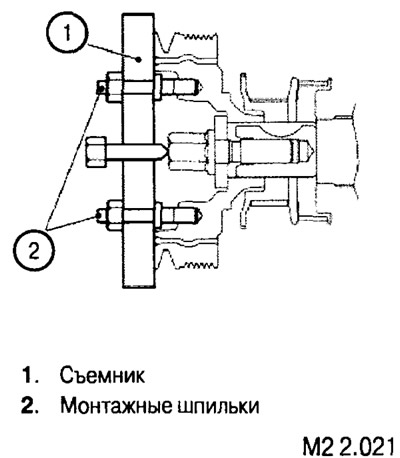

Removing the pulley

Use the mounting studs to loosen the pulley mounting screw (1) and holder (2), as it shown on the picture.

The pulley is removed using a puller (1).

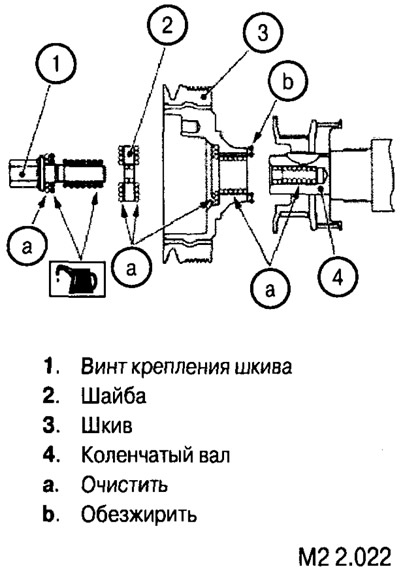

Pulley installation

When installing the pulley on the shaft, clean, degrease and lubricate the mounting elements as shown in the figure.

Put the pulley on the shaft and, holding it with the holder, tighten the fastening screw to a torque of 265 Nm (see fig. M2 2.020). Then completely loosen the screw and re-tighten it with a torque of 275 Nm.

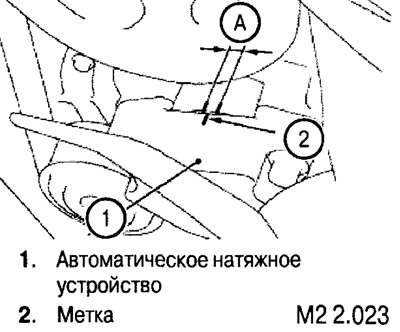

Attention: after installing the automatic tensioner and belt, turn the crankshaft clockwise (one or more times) and make sure that the mark on the auto-tensioner is within the zone «A», as it shown on the picture. Otherwise, the belt needs to be replaced.