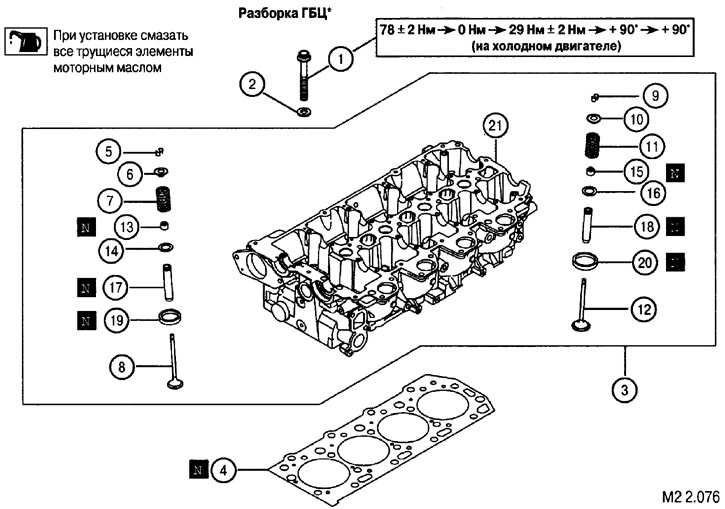

Elements of the cylinder head valve mechanism: 1. Cylinder head screws; 2. Washer; 3. cylinder head assembly; 4. Cylinder head gasket; 5. Valve crackers; 6. Valve spring plate; 7. Valve spring; 8. Inlet valve; 9. Valve cotters; 10. Valve spring plate; 11. Valve spring; 12. Exhaust valve; 13. Oil scraper cap; 14. Valve spring seat; 15. Oil scraper cap; 16. Valve spring seat; 17. Intake valve guide; 18. Exhaust valve guide; 19. Valve spring seat; 20. Valve spring seat; 21. cylinder head

Checking the head and elements of the valve group

After disassembling the cylinder head, remove the remnants of gaskets, oil, scale, etc. from its surfaces. After cleaning, blow out all channels with compressed air.

Inspect the condition of the mating surfaces, camshaft bearing beds, intake and exhaust valve seats.

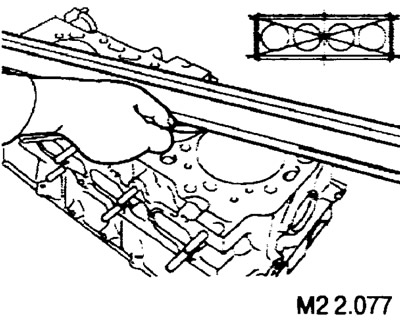

Checking the flatness of the cylinder head

Using a measuring ruler and feeler gauges, check the flatness of the mating surface (for gasket installation) in the directions shown in the figure.

Standard value: 0.05 mm.

Maximum allowable value: 0.2 mm.

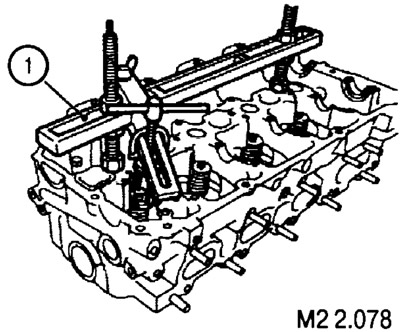

Removing the crackers securing the upper valve spring support

Attention: when removing crackers, set the piston of each cylinder to the TDC position.

1. To compress the valve spring in order to remove the valve cotters, install a tool on the cylinder head (1).

2. After compressing the valve spring, remove the crackers, plate and valve spring.

3. Remove the valve stem seal from the valve guide.

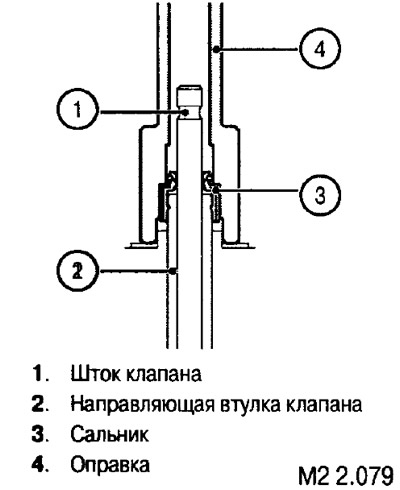

Installing valve stem seals (valve seals)

Note: The use of used seals is not allowed.

1. Apply a small amount of engine oil to the inner lip of the oil seal and press it onto the guide using a drift (4).

2. After installing new seals, install the valve spring and plate, compress the spring with a tool (1) (see fig. M2 2.078) and install the cotters on the valve stem.

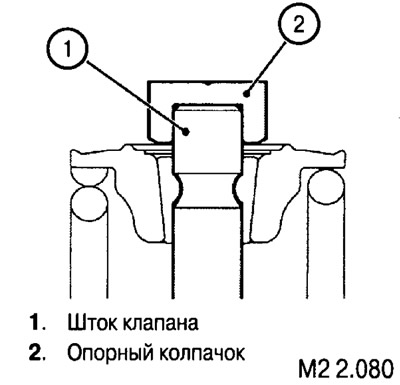

Valve stem cap

The valve stem cap must be fitted tightly.

Valve

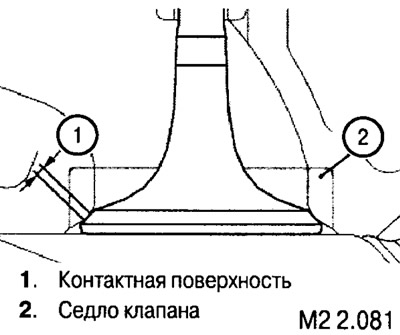

Checking the width of the contact surface and the thickness of the valve disc

1. The width of the contact surface must be uniform and located in the center of the valve face.

Standard value: 1.1-1.5 mm.

In case of incorrect contact, it is necessary to lap or replace the valve, replace or restore the geometric characteristics of the valve seat.

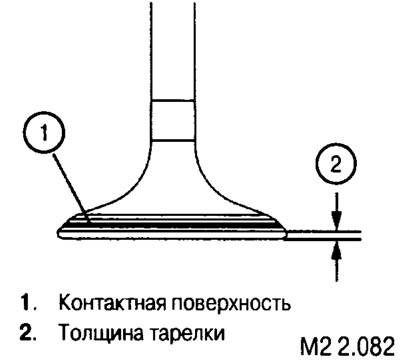

2. Measure the thickness of the valve disc.

Standard value:

- intake valve: 1.3mm;

- outlet valve: 1.5 mm.

Maximum allowable value:

- intake valve: 0.8mm;

- exhaust valve: 1.0 mm.

If the thickness is less than the limit, replace the valve.

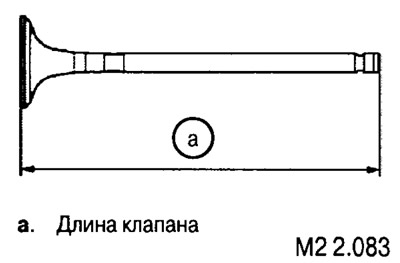

Valve length check

Standard value:

- intake valve: 107.58 mm;

- exhaust valve: 107.98 mm.

Maximum allowable value:

- intake valve: 107.08 mm;

- exhaust valve: 107.48 mm.

If the length is less than the limit, replace the valve.

Valve spring

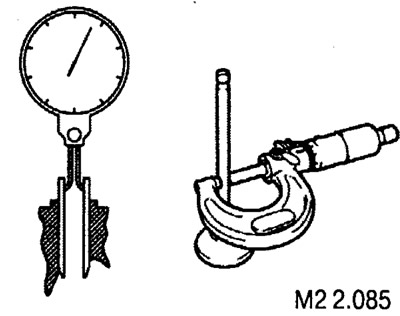

Measure spring height and yaw (in a free state).

Spring length:

- standard value: 54.3 mm;

- limit value: 53.3 mm.

Vertical Deviation:

- standard value: no more than 2°;

- limit value: 4°.

If the values obtained exceed the limits, the valve or guide may need to be replaced.