Attention: if the piston is replaced with a new one, the piston rings must also be replaced with new ones.

Check piston rings for damage, kinks or significant wear.

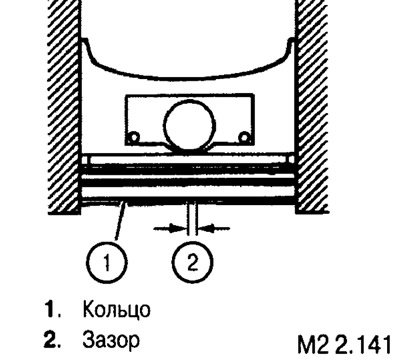

Check clearance between piston ring and piston groove. If the clearance exceeds the limit, replace the ring or piston or both.

Note: Remove carbon deposits from all piston grooves before taking measurements. Measure the clearance between the ring and the piston groove over the entire circumference of the ring.

Gap between ring and piston groove

Rated value:

- ring No. 1 - 0.06-0.11 mm;

- ring No. 2 - 0.05-0.08 mm;

- oil scraper ring - 0.02-0.07 mm.

Maximum permissible values:

- ring No. 1 - 0.15 mm;

- ring No. 2 - 0.15 mm;

- oil scraper ring - 0.10 mm.

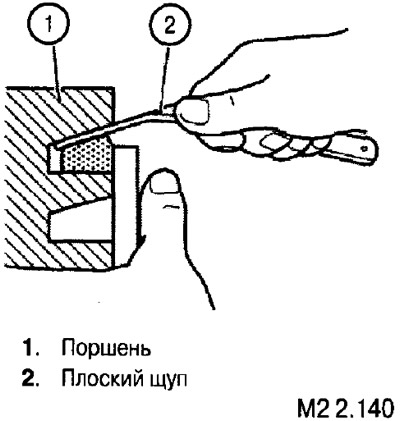

Checking the gap in the ring lock

Install the piston ring in the cylinder. Using the piston as a pusher, move the ring down so that it is at right angles to the cylinder walls. Measure the piston ring gap with a flat feeler gauge. If the gap in the lock exceeds the maximum allowable value, the ring must be replaced.

Rated value:

- rings No. 1 and No. 2 - 0.30-0.45 mm;

- oil scraper ring - 0.25-0.45 mm.

Limit value: 0.8 mm.