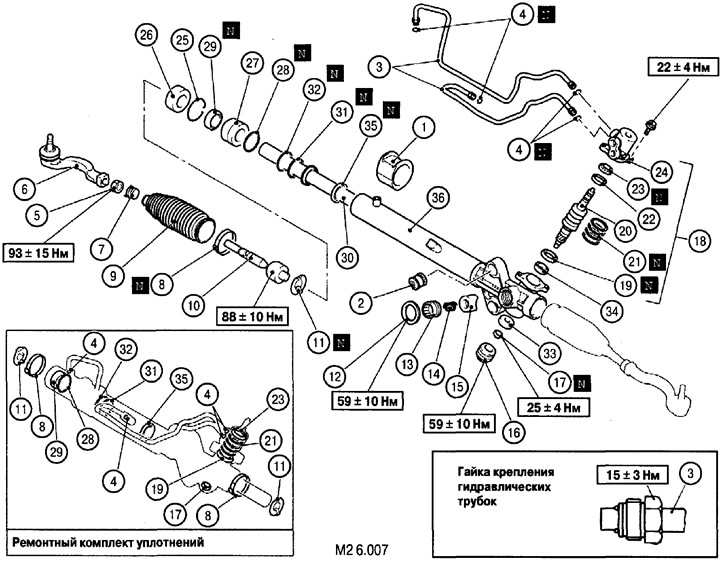

Steering gear design elements (for left-hand drive vehicles): 1. Rubber mounting sleeve steering gear; 2. Mounting rubber-metal bushing for mounting the steering mechanism; 3. Feed tubes (plum) oil in the power steering hydraulic cylinder; 4. O-ring (replace with a new one when reassembling); 5. Locknut; 6. Tie rod end; 7. Bellow collar (replace with a new one when reassembling); 8. Bellow collar (replace with a new one when reassembling); 9. Corrugated tie rod boot; 10. Tie rod; 11. Lock washer (replace with a new one when reassembling); 12. Locknut; 13. Threaded cover that regulates the pressure of the shoe on the rail; 14. Spring; 15. Rail support shoe; 16. Threaded plug; 17. Locknut (replace with a new one when reassembling); 18. Control valve assembly; 19. Bottom seal (replace with a new one when reassembling); 20. Gear and valve assembly; 21. O-ring (replace with a new one when reassembling); 22. Top bearing; 23. Upper seal (pi assembly to replace with a new one); 24. Valve body; 25. Snap ring; 26. Support stopper (replace with a new one when reassembling); 27. Support sleeve assembly; 28. O-ring (replace with a new one when reassembling); 29. Oil seal (replace with a new one when reassembling); 30. Steering rack assembly; 31. O-ring (replace with a new one when reassembling); 32. O-ring; 33. Lower bearing (replace with a new one when reassembling); 34. Needle bearing; 35. Oil seal (replace with a new one when reassembling); 36. Steering gear housing

Disassembly is carried out in the order indicated in Fig. M2 6.007. Assembly is carried out in the reverse order of disassembly.

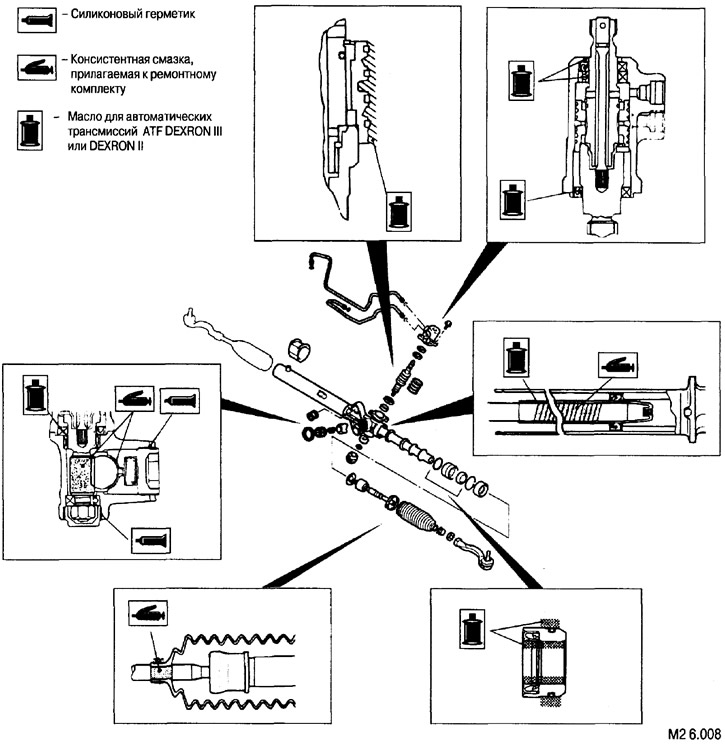

Lubrication points

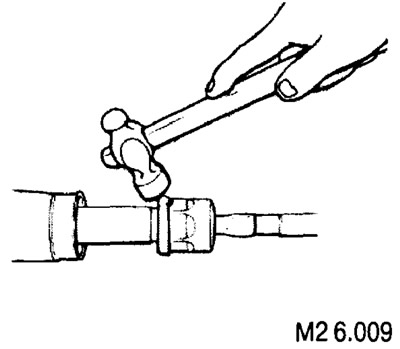

Installing the tie rod on the rack

After connecting the steering rod to the rack, use a hammer to bend the edges of the washer, fixing the hexagon of the housing of the inner joint of the steering rod.

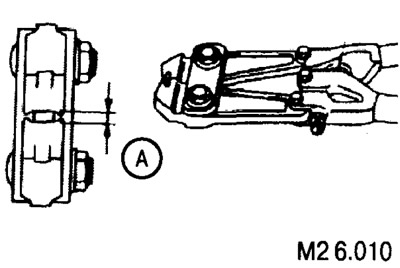

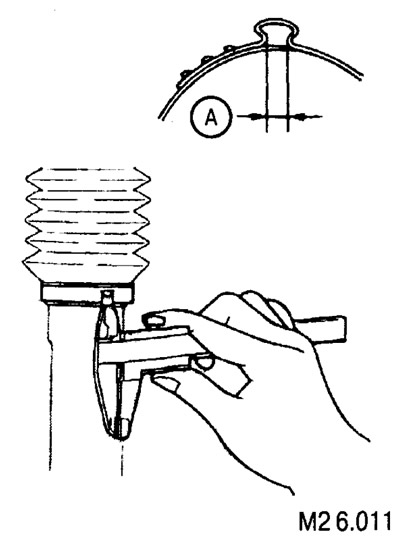

Installing the clamp

Fixation of the clamps is carried out using a special crimping tool (such as shown in Fig. M2 6.010).

With proper fixation, the size of corrugation A should be between 2.4 mm and 2.8 mm.

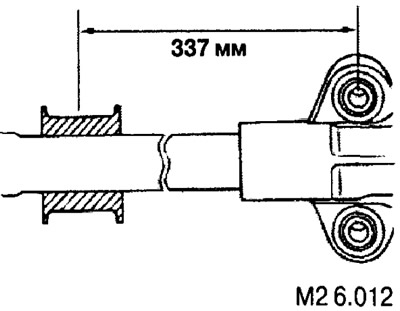

Installing the mounting rubber bushing

On fig. M2 6.012 shows the correct position of the mounting rubber bushing.