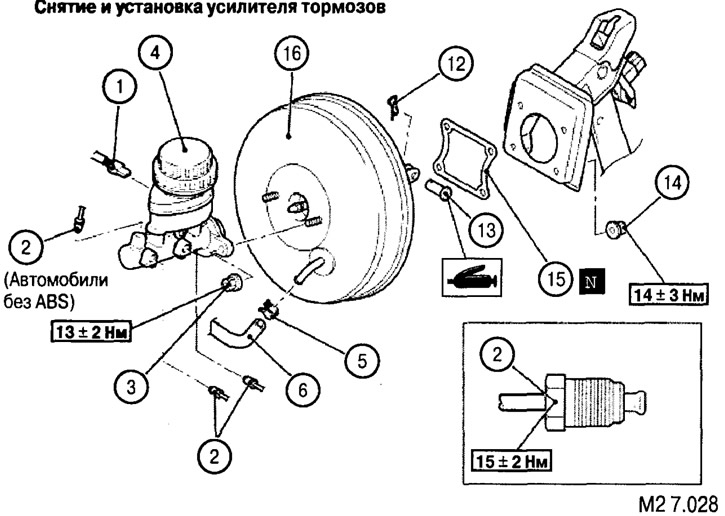

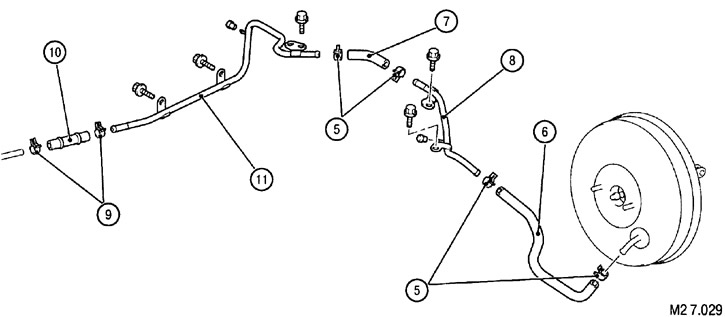

List of elements for drawings M2 7.028 - M2 7.029: 1. TJ level sensor connector. 2. Connecting the master cylinder to the brake line. 3. Master cylinder fixing nut. 4. Brake master cylinder: before installation, check and, if necessary, adjust the stroke of the push rod of the brake booster valve (see below). 5. Hose clamp. 6. Vacuum hose with built-in non-return valve. 7. Vacuum hose B. 8. Vacuum pipe B. 9. Hose clamp. 10. Vacuum hose A. 11. Vacuum tube A. 12. Pin clip. 13. Pin. 14. Brake booster fixing nut. 15. Seal. 16. Brake booster.

Removing

Note: The brake fluid must be drained before removal.

Removal is carried out in the order indicated in figures M2 7.028 - M2 7.029.

Installation

Installation is in the reverse order. After installation, it is necessary to fill the TJ brake system and bleed air.

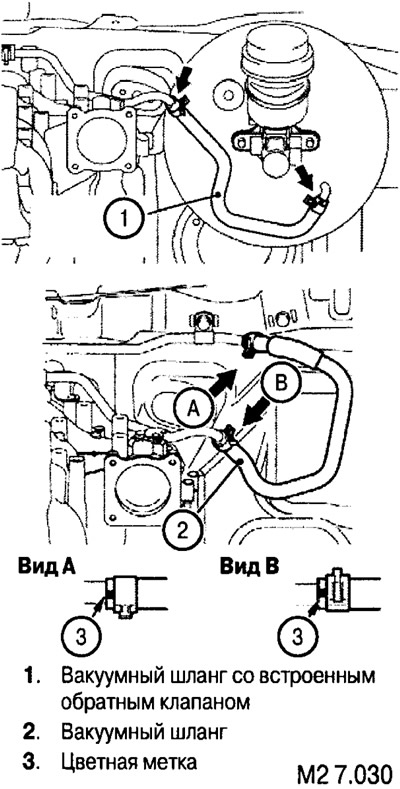

Vacuum hose and clamp connection

Install the vacuum hose and clamp in such a way that the colored marks on them are located as shown in the figure.

Checking and adjusting the stroke of the valve lifter

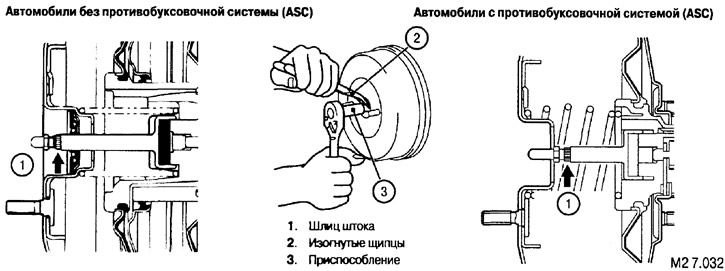

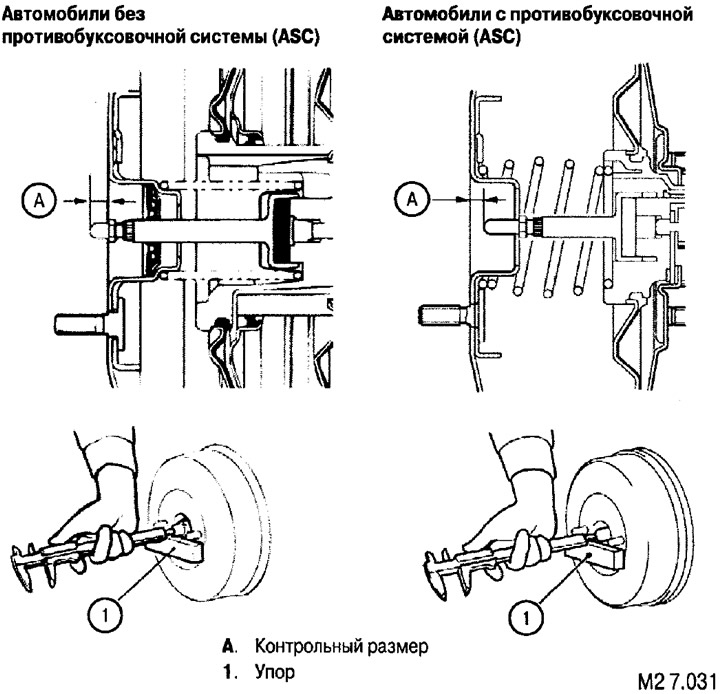

For a more accurate check, apply a negative pressure of 66.5 kPa to the brake booster. In this case, the standard values (A) are:

- for vehicles without traction control (ASC): 9.925-10.175 mm;

- for vehicles with traction control (ASC): 6.675-6.925 mm.

Without applied pressure of 66.5 kPa to the brake booster values (A) are:

- for vehicles without traction control (ASC): 8.925-9.175 mm;

- for vehicles with traction control (ASC): 7.675-7.925 mm.

If the stroke of the stem exceeds the specified value, adjust it by turning with a special tool, while holding the stem spline with curved pliers.